Dual-shaft water stirring type dish washing machine

A dishwasher and water-repelling blade technology, which is applied to the washing machine/washing machine for tableware, the parts of the washing machine/rinsing washing machine for tableware, cleaning equipment, etc. It can reduce the adsorption of food residues, reduce the cost of use, and improve the self-cleaning ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

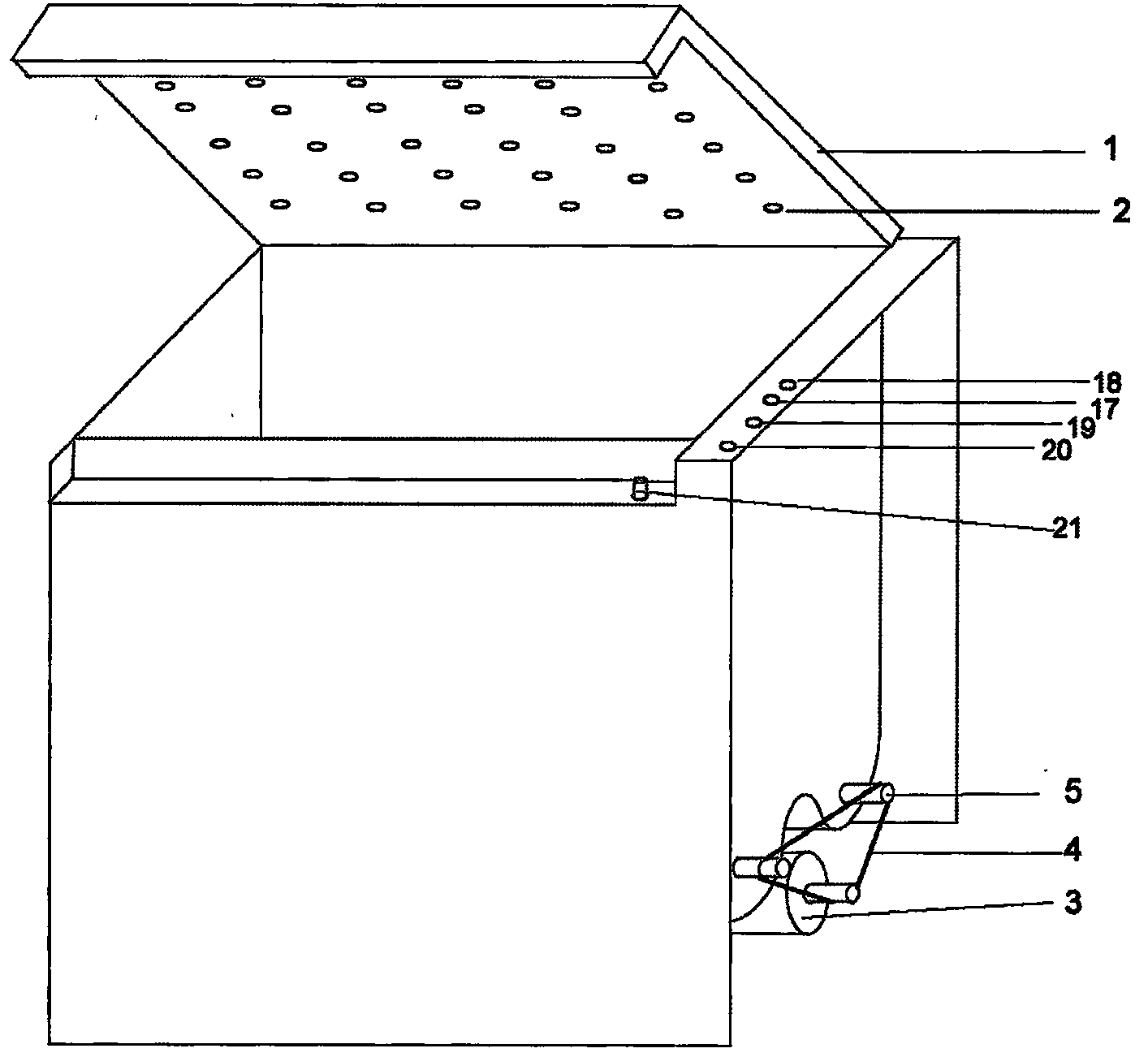

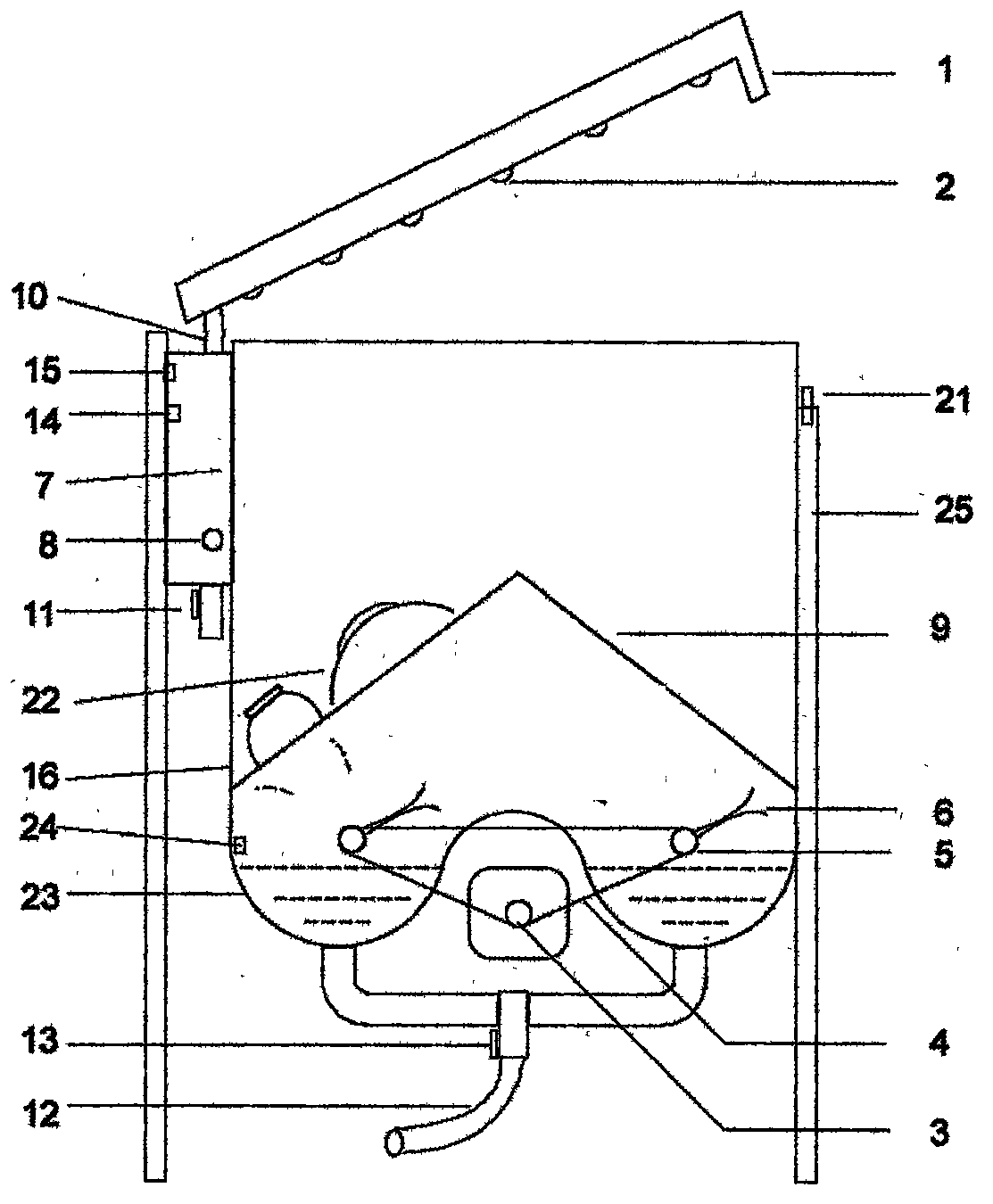

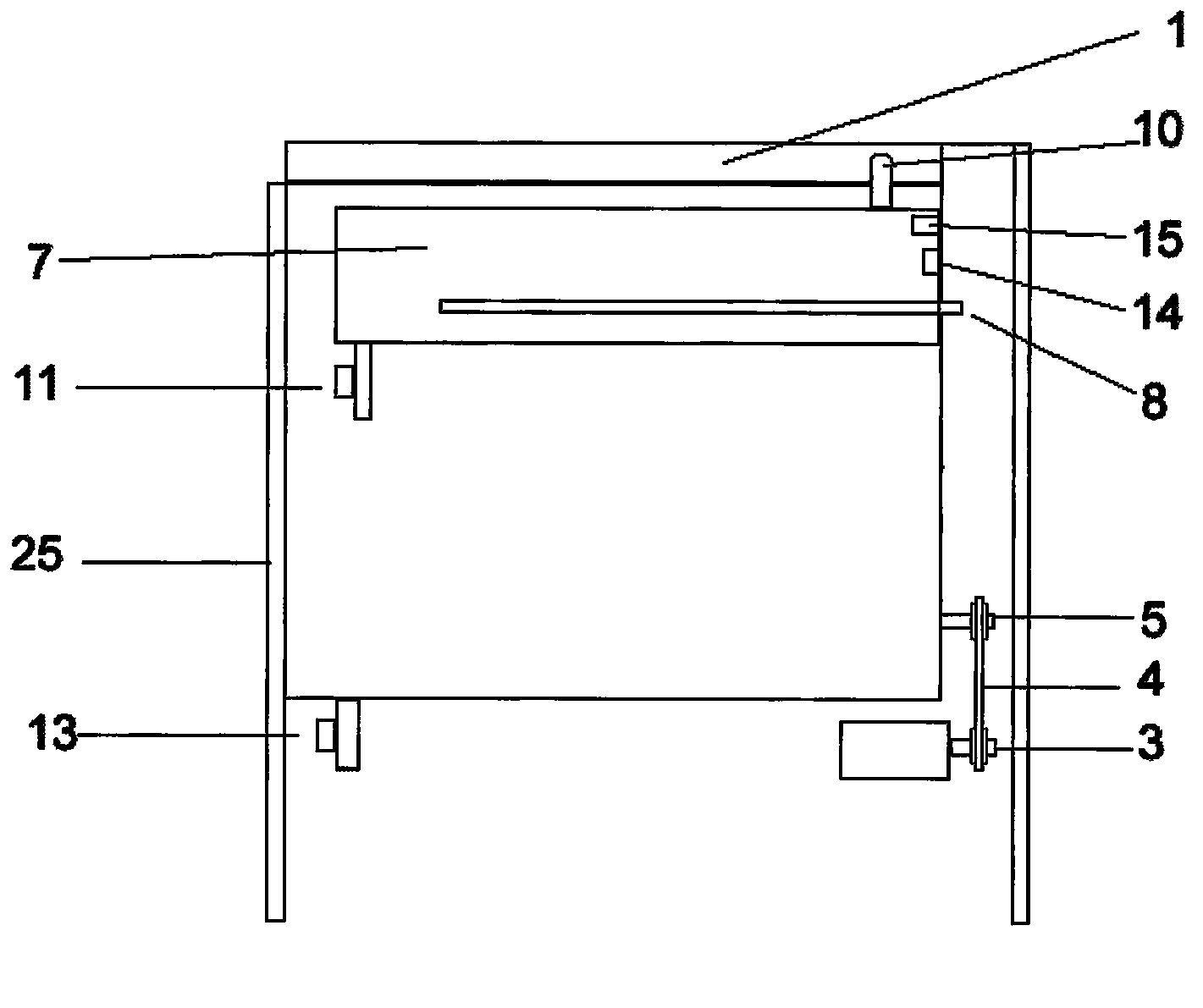

[0024] Plug in the dishwasher, remove the water spray cover [1], add an appropriate amount of detergent, put the pots, bowls [22], cups and other tableware that need to be cleaned on the "herringbone" shaped bowl with the mouth facing down on the shelf [9]. After putting the tableware, you can choose manual or automatic washing method according to the situation.

[0025] If you choose the automatic washing method, you only need to cover the water spray cover. When the cover is closed, the door control safety switch [23] will be pressed down to connect the circuit (during use, if the cover is opened, the door control safety switch The circuit will be disconnected and the motor will stop running to ensure safety). Then press the automatic washing button, the single chip microcomputer will control in sequence according to the following procedures:

[0026] 1. Inlet water heating. The program first starts the water tank water level gauge [15] to detect the water level of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com