Liquid iron slag filter

A filter and iron slag technology, applied in the direction of fixed filter element filter, filtration separation, solid separation, etc., can solve the problems of shortened filter element service life, filter element damage, equipment blockage, etc., to strengthen adsorption capacity and improve filtration capacity. , to avoid the effect of direct impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

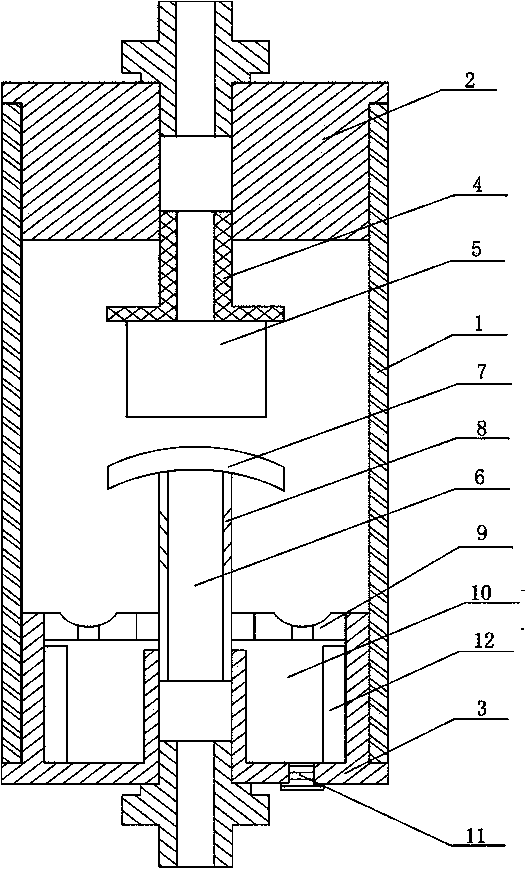

[0018] Such as figure 1 As shown, the liquid iron slag filter of the present invention includes a housing 1. On both ends of the housing 1, an upper head 2 and a lower head 3 are respectively installed, and the upper head 2 and the lower head 3 are both provided with communication A filter joint 4 is installed on the communicating hole of the upper head 2, a filter element 5 is installed on the filter joint 4, a spray tube 6 is installed on the communicating hole of the lower head 3, and the end of the spray tube 6 is installed The baffle 7 is provided with a plurality of spray holes 8 on the side wall of the spray pipe 6, and a filter plate 9 is sleeved on the spray pipe 6. The filter plate 9, the lower head 3, and the side wall of the housing 1 are enclosed to form a settlement In the chamber 10, an adsorption magnet 12 is installed in the settling chamber 10, and a discharge hole and a matching seal 11 are provided on the lower head 3, and the seal 11 can be disassembled to...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap