High-purity copper powder production process utilizing waste copper enameled wires

A production process and enameled wire technology, applied in the field of high-purity copper powder production process, can solve the problems of low use value and economic value, low copper powder grade, and low output, and achieve high use value and economic value. The effect of a short production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

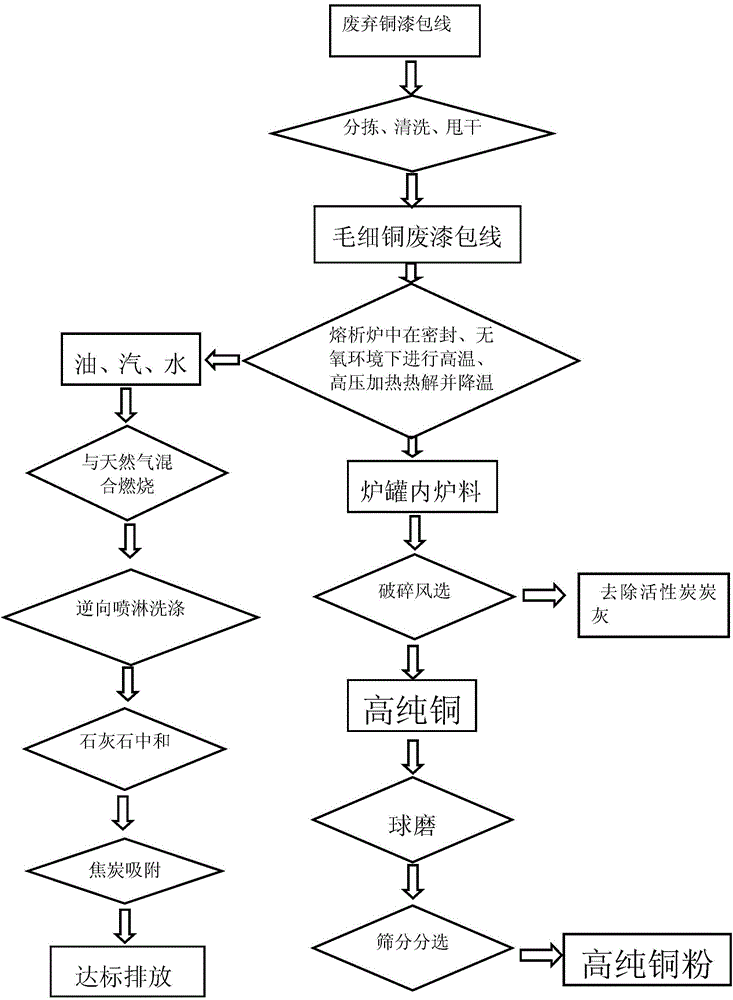

[0020] Such as figure 1 The shown high-purity copper powder production process utilizing waste copper enameled wire includes the following steps:

[0021] S1. Sorting, cleaning and drying the waste copper enameled wires in sequence. The sorting operation is to pick the capillary copper enameled wires with a diameter of 0.04mm to 0.1mm; since the copper enameled wires are thinner, the copper quality is higher. Therefore, the grade of high-purity copper powder produced by capillary copper enameled wire under the condition of this diameter will be very high; moreover, dust pollution can be removed after washing, and there are no other pollutants except paint;

[0022] S2. Send the selected capillary copper enameled wire into a melting furnace for heating and pyrolysis in a sealed and oxygen-free environment, and then perform forced cooling after pyrolysis;

[0023] S3. Perform crushing and winnowing treatment on the charge formed by heating and pyrolyzing in the melting furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com