Material taking/sending mechanical arm

A technology of manipulators and manipulators, applied in the field of manipulators, can solve problems such as reducing the free space of production equipment, reducing productivity, and the single feeding or retrieving function of manipulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

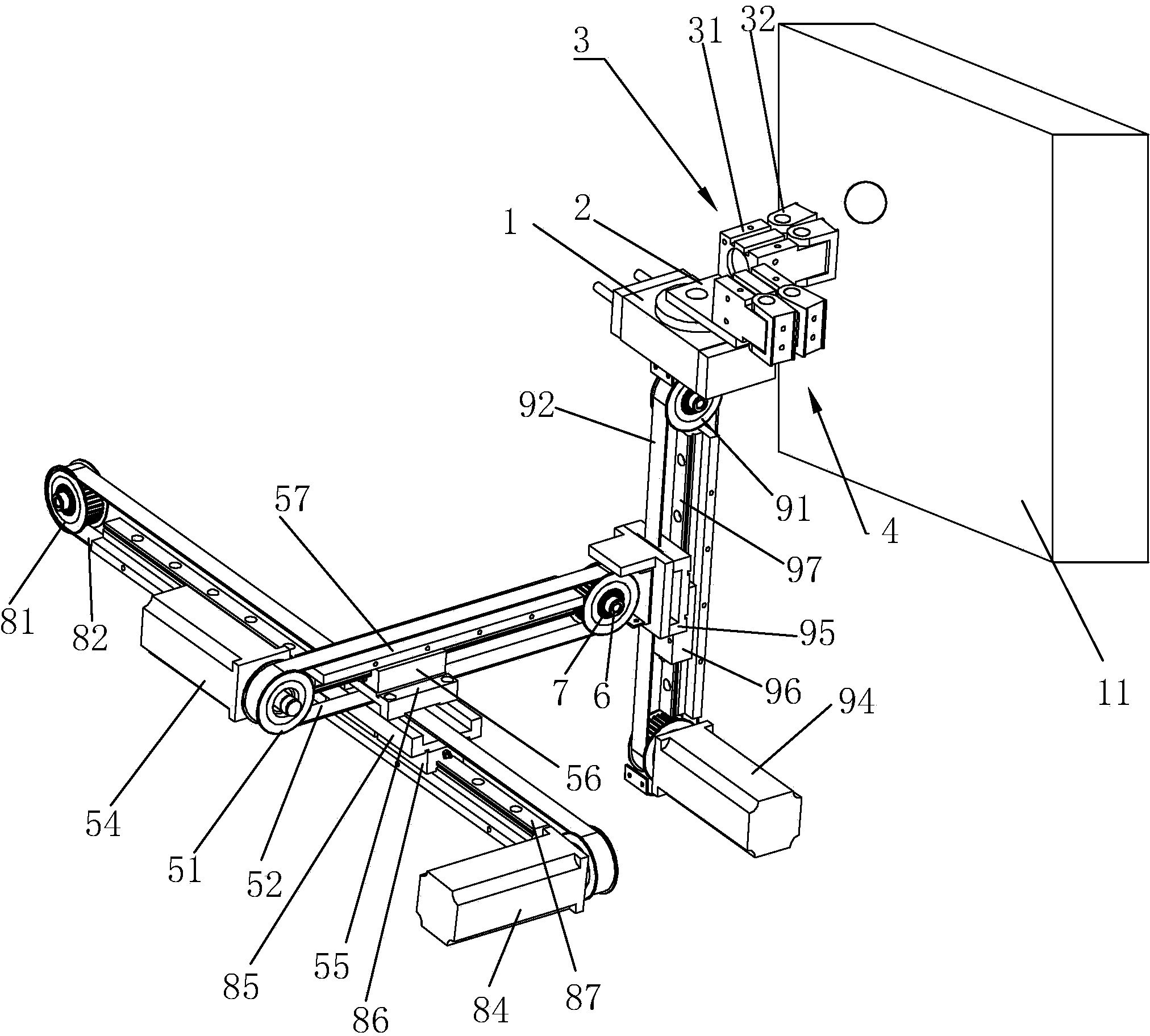

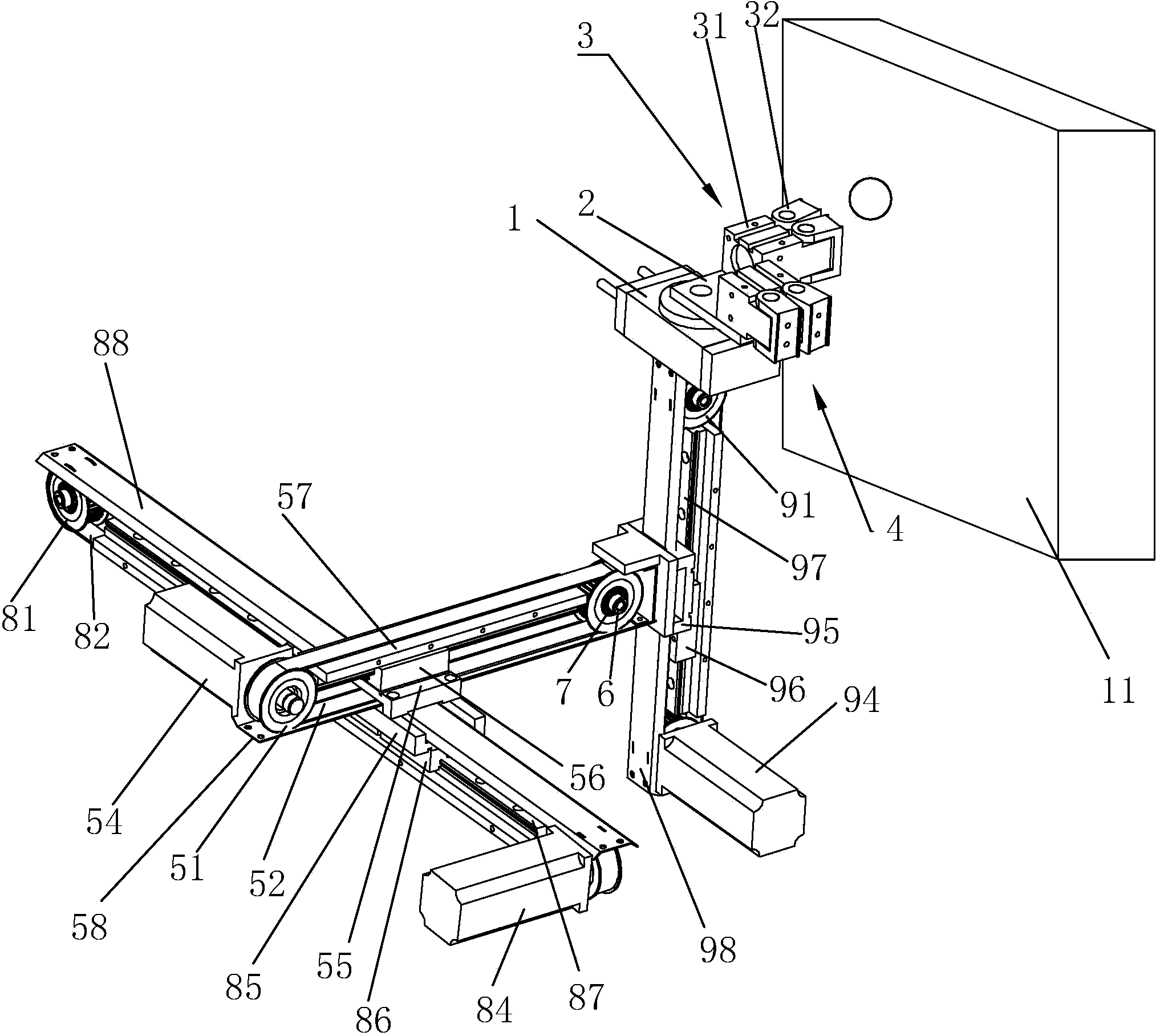

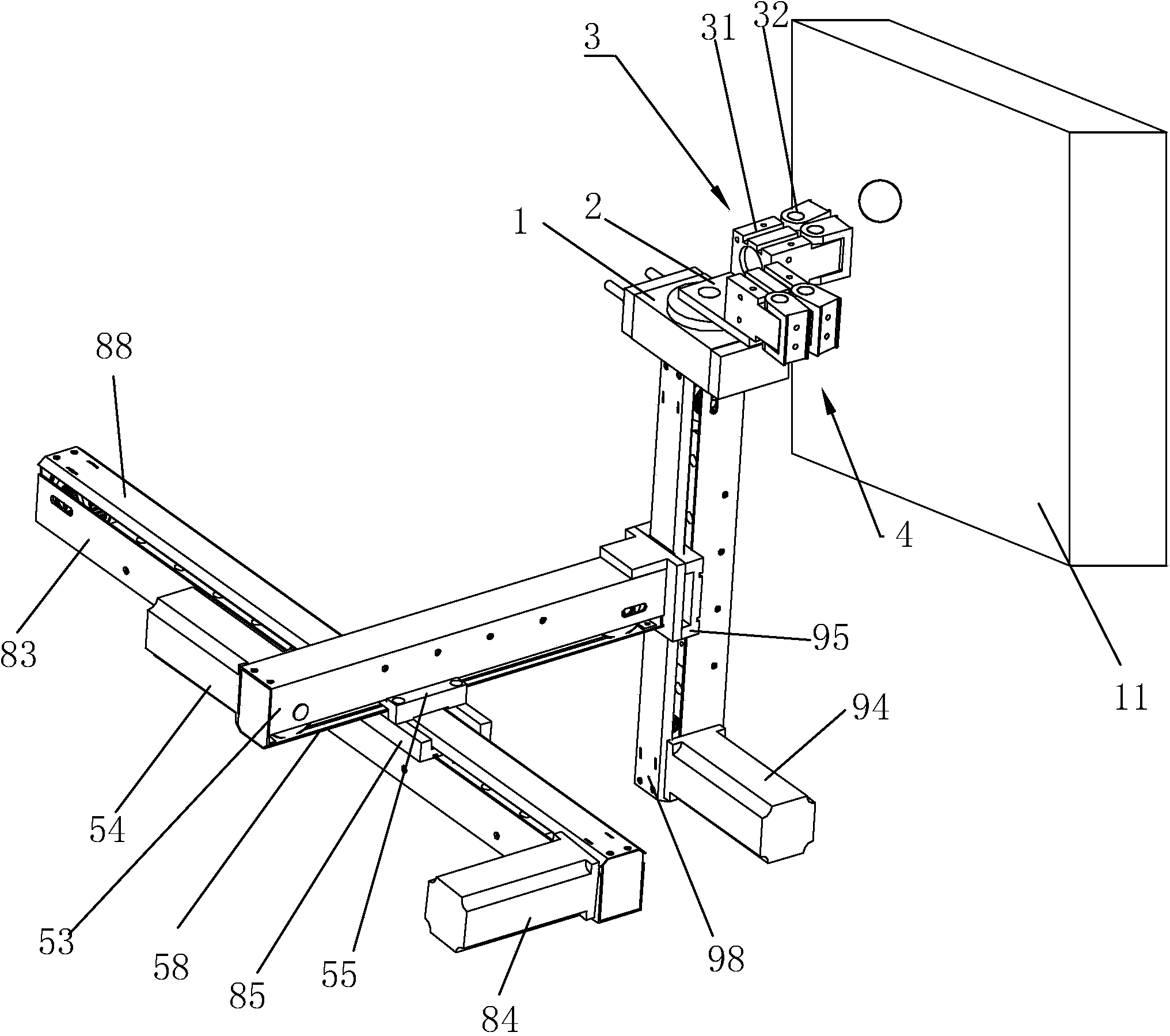

[0028] refer to Figure 1 to Figure 6 The embodiment of the feeding manipulator of the present invention will be further described.

[0029]A kind of feeding manipulator comprises mounting plate 2 and mechanical arm, and described mechanical arm is installed on described mounting plate 2, and described mechanical arm comprises feeding arm 3 and retrieving arm 4, and described feeding arm 3 and retrieving arm 4 are located on the same horizontal plane and arranged vertically to each other. The feeding arm 3 and the retrieving arm 4 both include an arm seat 31, and two mechanical fingers 32 are arranged on the arm seat 31. Drive the mechanical finger 32 to rotate and clamp or loosen the secondary driving mechanism of the workpiece to be processed. The main driving mechanism 1 for driving the mounting plate 2 to rotate around its center is provided on the mounting plate 2, and the mounting plate 2 is also provided with There is a first driving device for driving it to move in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com