Biomass porous phase change temperature adjustment and humidifying material and preparation method thereof

A phase change material, temperature and humidity control technology, applied in ceramic products, other household appliances, applications, etc., can solve the problem of consuming a lot of energy, and achieve the effect of saving raw materials, continuous pore size, and increasing varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the embodiments.

[0027] 1. Raw materials

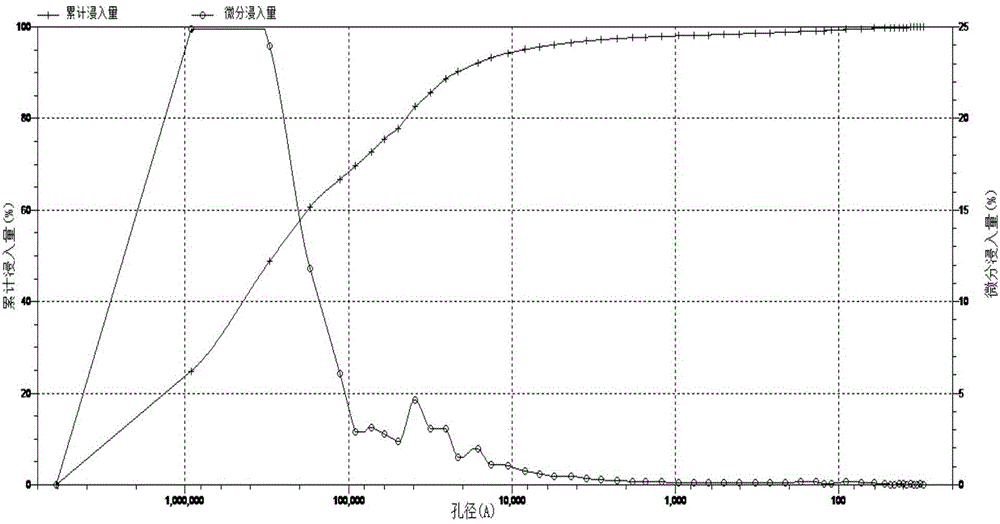

[0028] (1) Waste walnut shells: After pickling, they are dried and ground, passed through a 0.63mm sieve, and then physically activated. After activation, the pore size distribution of walnut shells is concentrated in 10 4 nm~10 5 Between nm, the porosity is as high as 76%.

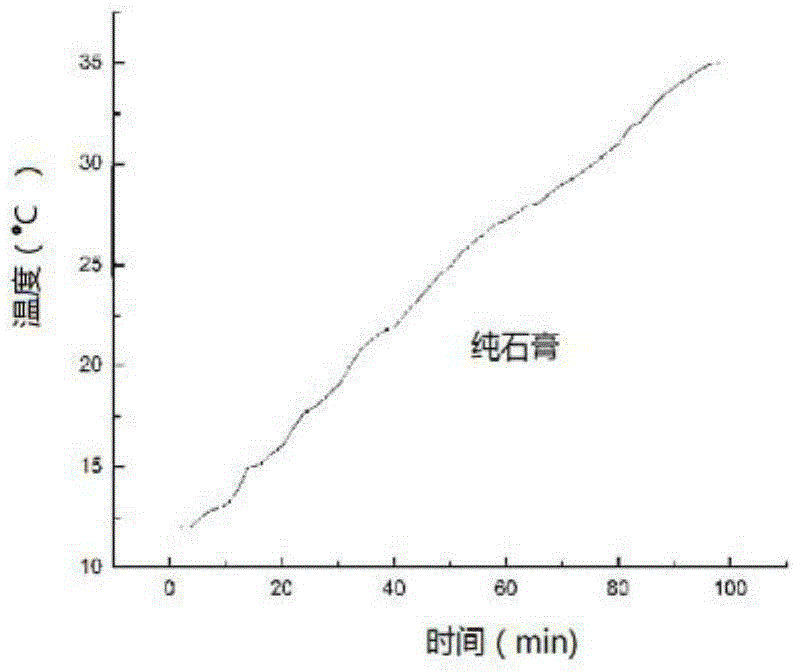

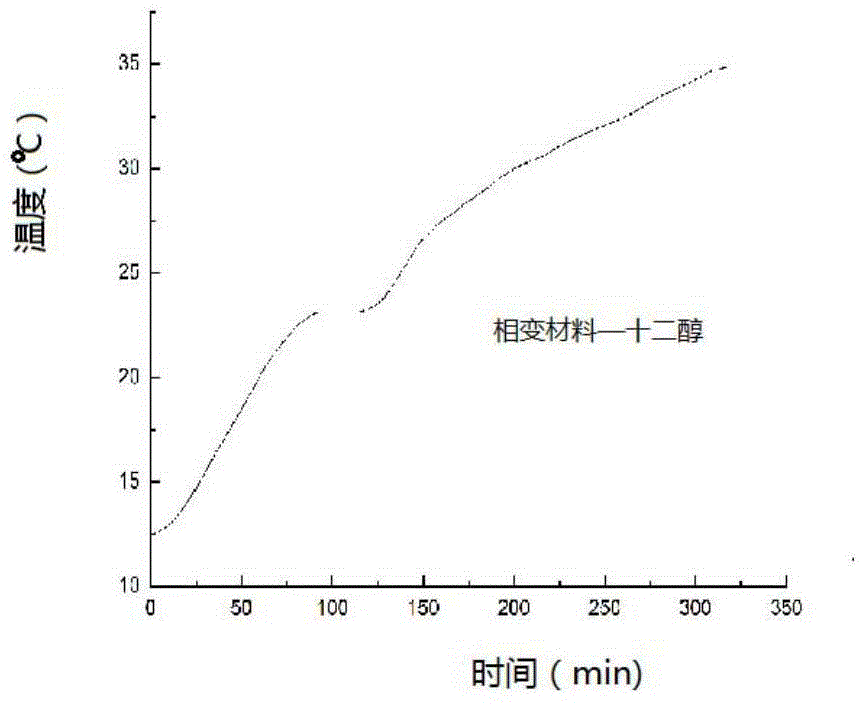

[0029] (2) Phase change material: use paraffin or dodecanol; paraffin: solid, melting point 45℃~48℃; dodecanol: liquid, melting point 20℃~24℃.

[0030] 2. Walnut shell activation system

[0031]

[0032] 3. The best adsorption ratio

[0033]

[0034] A preparation method of biomass porous phase change temperature and humidity control material includes the following steps:

[0035] 1) Pickling the walnut shell raw materials and baking at 105°C for 24 hours. Take the dried walnut shell raw material, put it into a ball mill, ball mill for 6 hours, and then use a vibrating mill for furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com