A kind of industrialized production method of red pigment with less machine surface precipitation and its machine surface precipitation detection method

A production method and technology for pigments, applied in chemical instruments and methods, organic dyes, color/spectral property measurement, etc., can solve problems such as difficulty in cleaning the machine surface, serious precipitation of pigments on the machine surface, and loss of pigment coloring. Low requirements, short reaction time, improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

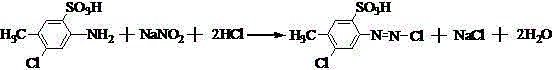

[0029] 1) Put 175Kg of 2-chloro-4-aminotoluene-5-sodium sulfonate into a common reaction kettle, add 2000Kg of water, raise the temperature to 70°C until completely dissolved, quickly add 215Kg of hydrochloric acid with a content of 30%, and then incubate at 0°C for 10 Add 251Kg of 20% sodium nitrite solution in 1 minute and carry out diazotization stirring reaction for 1 hour;

[0030] 2) Inject 145Kg of 3-hydroxy-2-naphthoic acid into the coupling reactor, add 250Kg of liquid caustic soda with a content of 30%, stir until the 3-hydroxy-2-naphthoic acid is dissolved, and add 35kg of rosin;

[0031] 3) Add the diazo solution into the coupling reaction kettle at 15°C for coupling reaction, and stir for 2 hours after adding the diazo solution;

[0032] 4) Raise the temperature to 38°C, inject 280Kg of calcium chloride into the coupling reaction kettle, stir for 1 hour and 15 minutes, then raise the temperature to 95°C for post-treatment, keep the heat for 30 minutes, cool down a...

Embodiment 2

[0035] 1) Put 175Kg of 2-chloro-4-aminotoluene-5-sulfonic acid into a common reaction kettle, add 2000Kg of water; quickly add 215Kg of 30% hydrochloric acid, and then add 20% sodium nitrite solution within 20 minutes at 10°C 251Kg carried out diazotization stirring reaction for 2 hours;

[0036] 2) Inject 148Kg of 3-hydroxy-2-naphthoic acid into the coupling reaction kettle, add 255Kg of liquid caustic soda with a content of 30%, and stir until the 3-hydroxy-2-naphthoic acid is dissolved;

[0037] 3) Add the diazo solution into the coupling reaction kettle at 10°C for coupling reaction, stir for 2 hours after adding the diazo solution, and add 17.5kg of S-rosin;

[0038] 4) Raise the temperature to 35°C, inject 350Kg of calcium chloride into the coupling reaction kettle, stir for 30 minutes, heat up to 95°C for post-treatment, keep warm for 10 minutes, cool down and filter, and dry at 90°C to obtain a pigment red weight of 351kg. The application performance of the pigment re...

Embodiment 3

[0040] 1) Put 175Kg of 2-chloro-4-aminotoluene-5-sulfonic acid into a common reaction kettle, add 2000Kg of water; quickly add 215Kg of 30% hydrochloric acid, and then add 20% sodium nitrite within 15 minutes at -2°C Solution 251Kg carried out diazotization stirring reaction for 1 hour;

[0041] 2) Inject 145Kg of 3-hydroxy-2-naphthoic acid into the coupling reaction kettle, add 250Kg of liquid caustic soda with a content of 30%, stir until the 3-hydroxy-2-naphthoic acid is dissolved, and add 30kg of stearic acid;

[0042] 3) Add the diazo solution into the coupling reaction kettle at 15°C for coupling reaction, and stir for 1.5 hours after adding the diazo solution;

[0043] 4) Raise the temperature to 40°C, inject 320Kg of calcium chloride into the coupling reaction kettle, stir for 15 minutes, heat up to 85°C for post-treatment, keep warm for 20 minutes, cool down and filter, and dry at 90°C to obtain Pigment Red with a weight of 359kg. The application performance of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com