Method for producing beer through direct fermentation of malt flour

A malt powder and direct technology, applied in the field of brewing wine, can solve the problems of high energy consumption and capital investment in equipment, not adapting to energy saving and environmental protection, and high operating costs, and achieve the effect of speeding up production progress, retaining active substances and fresh taste, and moving flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A method of directly fermenting malt powder to produce beer, adding malt powder and water to a fermentation tank, heating while stirring, sterilizing at 78°C for 30 minutes, cooling to 58°C for saccharification, adding hops and brewer's yeast, stirring evenly, 28 °C fermentation for 48 hours.

[0022] The added amounts of hops and brewer's yeast were 0.2 wt. % and 0.05 wt. % of the malt powder, respectively.

[0023] Open the vent valve to vent during fermentation.

[0024] After fermentation, close the exhaust valve and keep the pressure for 16 hours to cool the wine to 0°C.

Embodiment 2

[0026] A method for directly fermenting malt powder to produce beer, adding malt powder and water to a fermentation tank, heating while stirring, sterilizing at 82°C for 40 minutes, cooling to 62°C for saccharification, adding hops and brewer's yeast, stirring evenly, 31 ℃ fermentation for 72 hours.

[0027] The added amounts of hops and brewer's yeast were 0.5 wt. % and 0.12 wt. % of the malt powder, respectively.

[0028] Open the vent valve to vent during fermentation.

[0029] After fermentation, close the exhaust valve and keep the pressure for 24 hours to cool the wine to 5°C.

Embodiment 3

[0031] A method for directly fermenting malt powder to produce beer, adding malt powder and water into a fermentation tank, heating while stirring, sterilizing at 80° C. for 35 minutes, cooling to 60° C. for saccharification, adding hops and brewer’s yeast, stirring evenly, and stirring for 30 minutes. ℃ fermentation for 60 hours.

[0032] The added amounts of hops and brewer's yeast were 0.3 wt. % and 0.08 wt. % of the malt powder, respectively.

[0033] Open the vent valve to vent during fermentation.

[0034] After fermentation, close the exhaust valve and keep the pressure for 20 hours to cool the wine to 2°C.

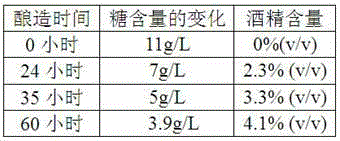

[0035] The saccharified liquid with a sugar content of 11% was fermented, and the changes in sugar content and alcohol content were detected by sampling, as shown in the table below.

[0036]

[0037] Each index of the product conforms to the national standard.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com