Fabricated lattice type H-shaped bearing steel support

A prefabricated, H-beam technology, applied in the direction of house structure support, house structure support, pillars, etc., can solve the problems of low safety of the force transmission method, difficulty in ensuring the verticality of the bracket, and difficulty in ensuring the verticality, so as to achieve force transmission. The method is safe and reliable, the assembly process is convenient and efficient, and the verticality is easily guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

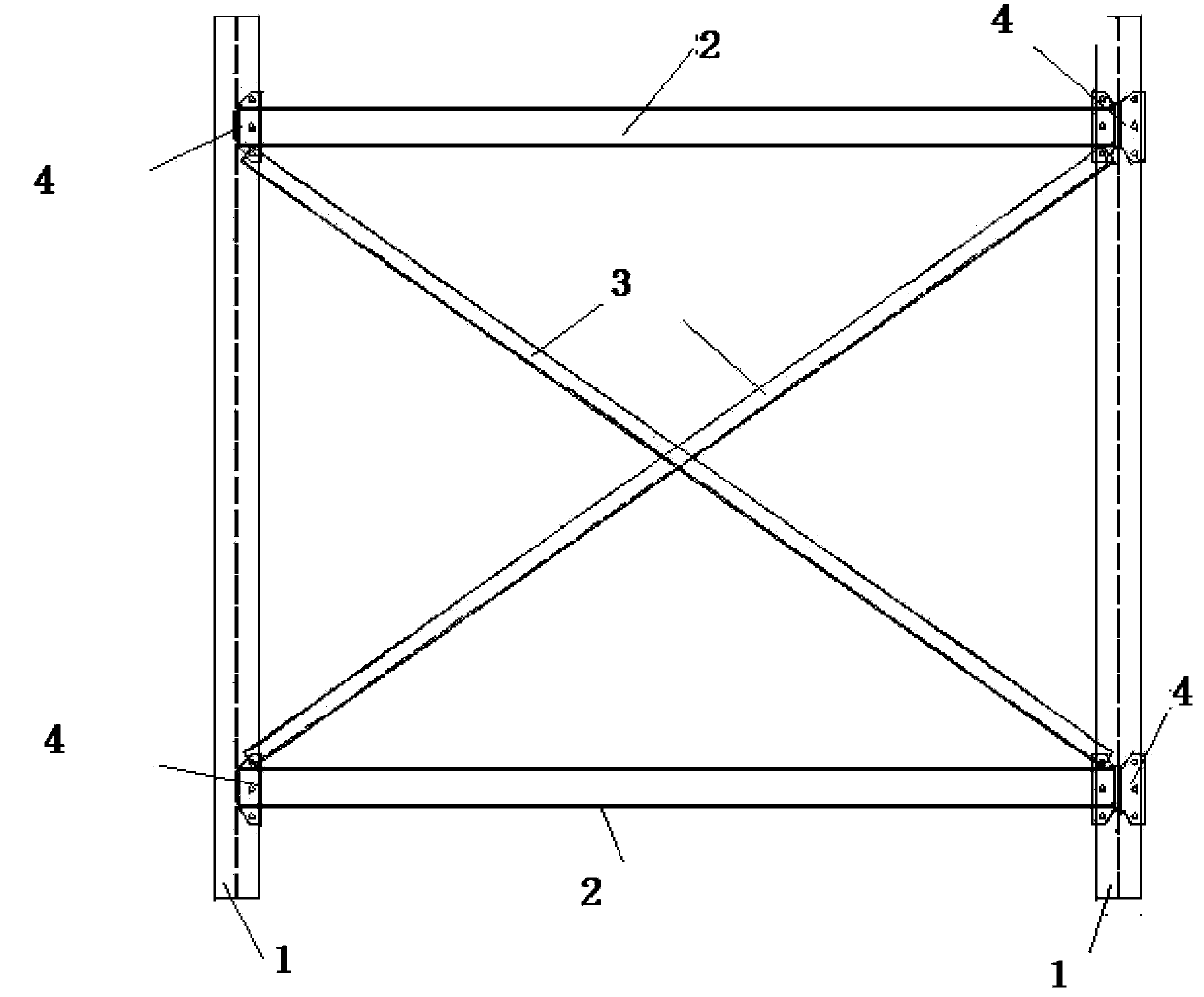

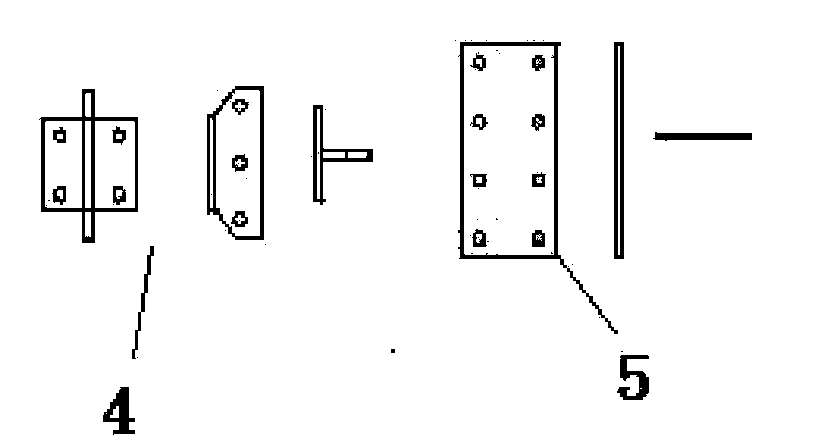

[0020] Such as figure 1 As shown, a framework for assembly of an assembled lattice load-bearing H-shaped steel bracket, including steel 1, horizontal support 2, oblique support 3 and T-shaped connecting plate 4, shaped steel 1 is bolted to T-shaped connecting plate 4, and horizontal support 2 And the diagonal support 3 forms a frame-shaped skeleton through the T-shaped connecting plate 4 and bolts and the steel section 1, wherein the horizontal support 2 is used for connecting the section steel 1 horizontally, and the diagonal support 3 is used for connecting the section steel 1 diagonally.

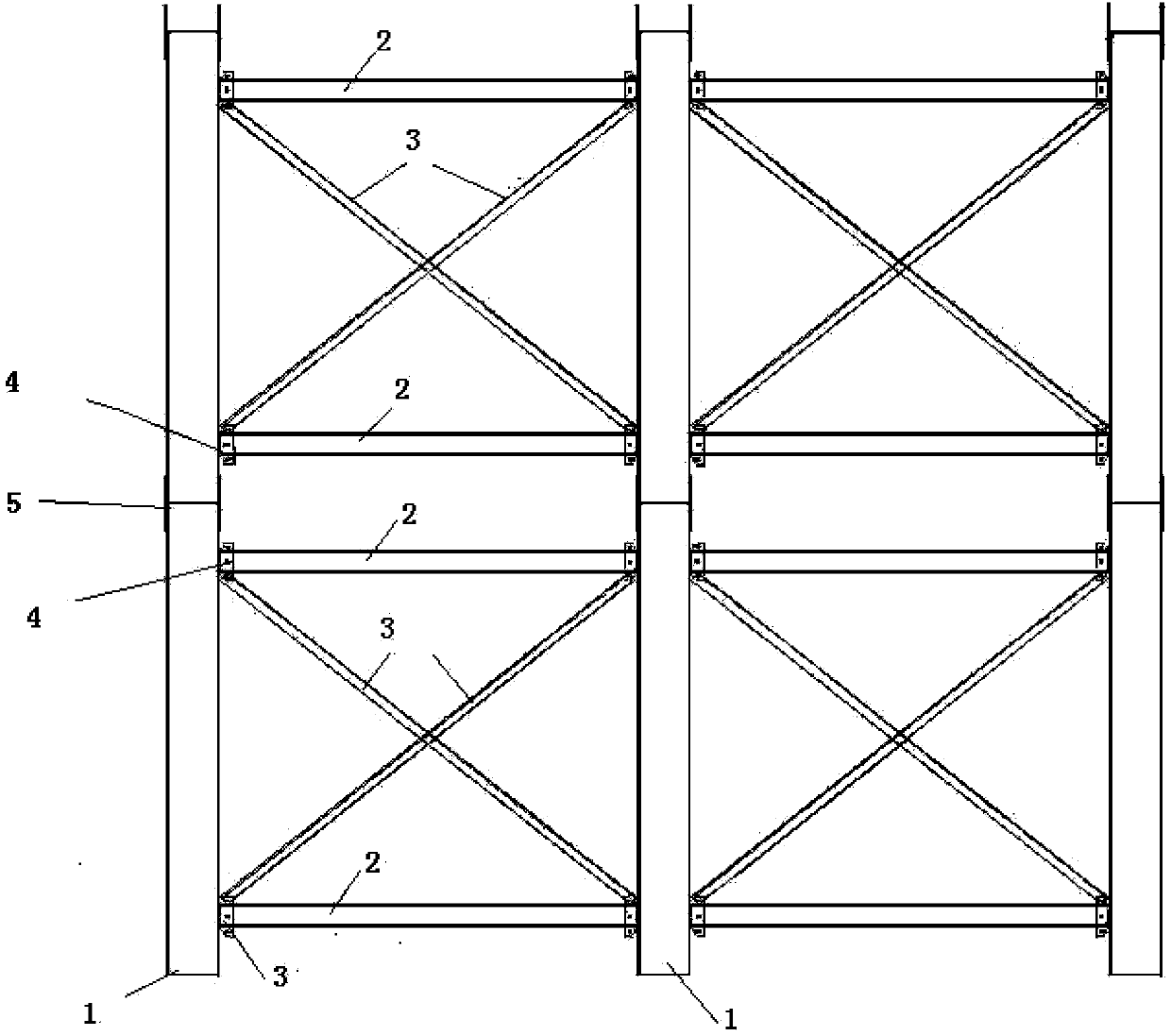

[0021] Such as figure 2 As shown, a prefabricated lattice structure load-bearing H-shaped steel support is obtained by expanding the above frame, and is connected and expanded through the T-shaped connecting plate 4, horizontal support 2, and oblique support 3 to the above frame, and the profile steel 1 of different frames in the vertical height direction passes Connecting plate 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com