fuel supply system

A fuel supply system and fuel technology, which are applied in charging systems, fuel injection devices, liquid fuel feeders, etc., can solve the problems of difficult components, complex structures, and generation of sealing points, and achieve improved accessibility and reduced quantity. , the effect of structure simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

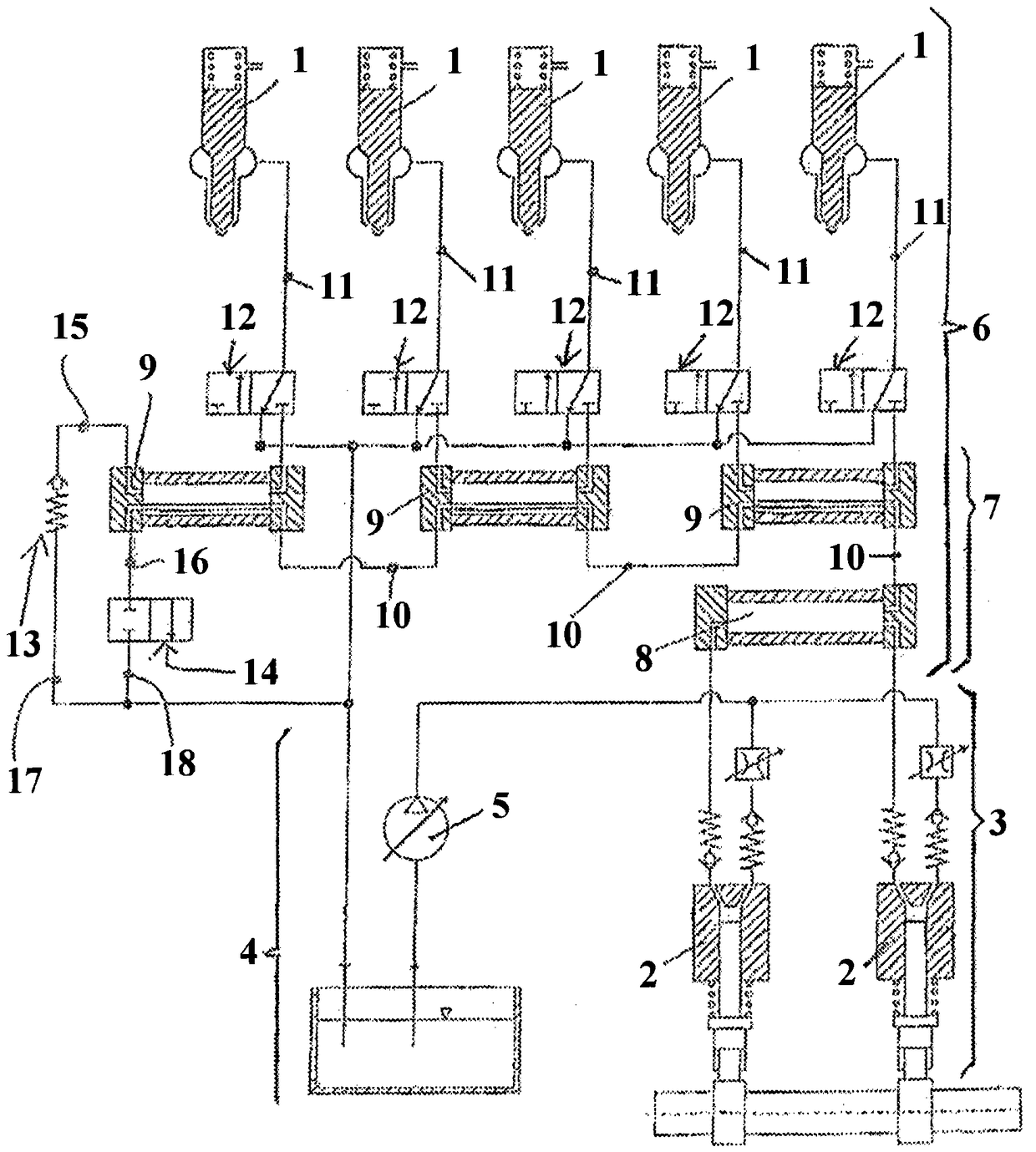

[0042] The invention relates to a fuel supply system for an internal combustion engine, especially a common rail fuel supply system, especially designed as a large diesel engine or a marine diesel engine. The basic structure of this fuel supply system has been referred to figure 1 to describe.

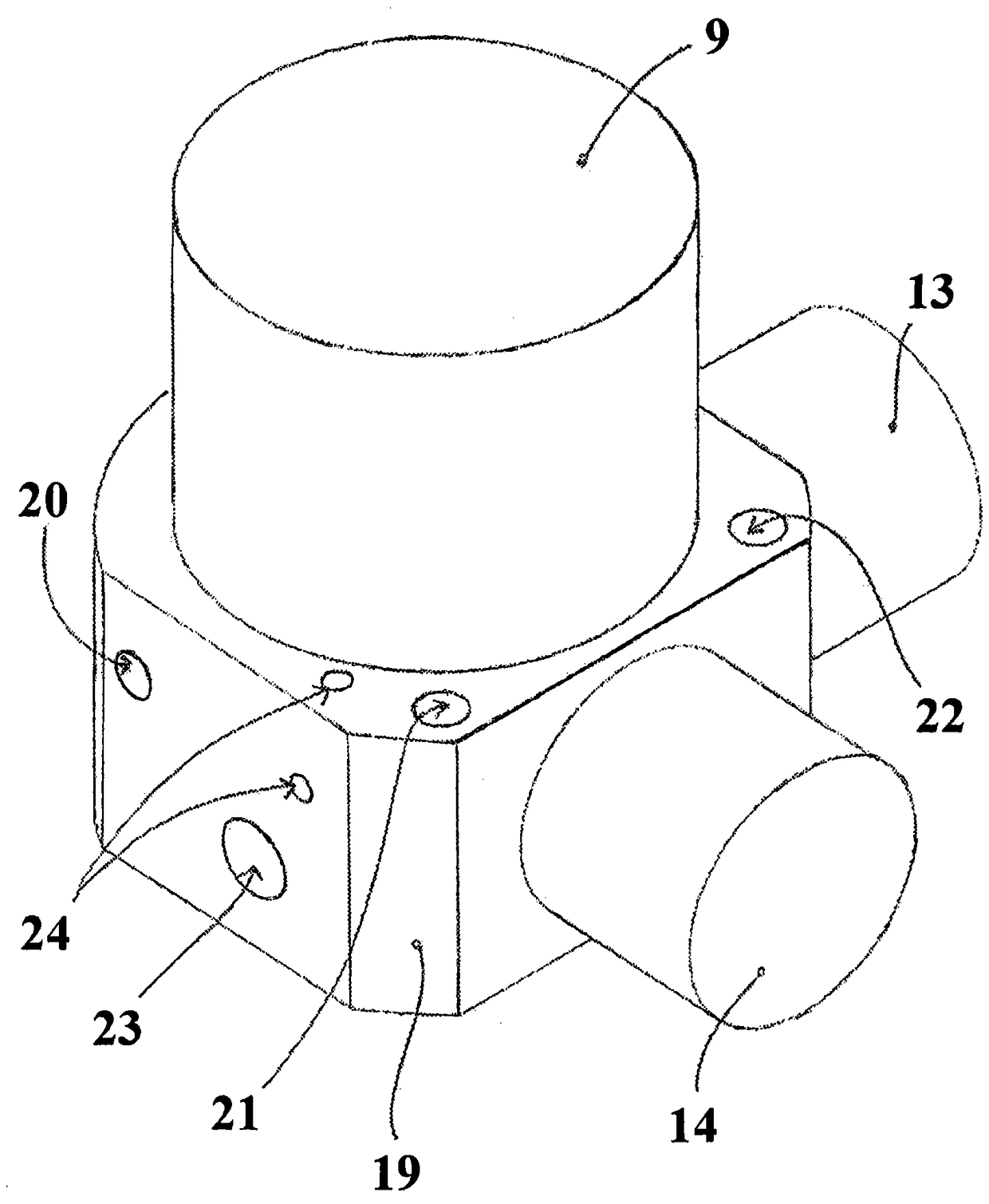

[0043] The invention concerns the details of the fuel supply system by means of which, in the area of the pressure accumulator 9 interacting with the pressure limiting valve 13 and the flushing valve 14 , the plumbing work can be reduced. For details on this, refer to the following figure 2 to describe.

[0044] therefore, figure 2 Assignment of a valve block 19 to the pressure accumulator unit 9 interacting with the pressure limiting valve 13 and the flushing valve 14 is shown, wherein the pressure accumulator unit 9 acts directly on the valve block 19 , wherein the valve block 19 also accommodates or carries the pressure limiting valve 13 and flush valve 14.

[0045] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com