Bionic impeller for exhaust hood

A technology for range hoods and range hoods is applied in the fields of removing range hoods, applications, and household stoves, etc., and can solve the problems of reducing the shedding frequency of vortex shedding of leading edge pressure impacting trailing edge, reducing the working efficiency of fans, increasing motor load, etc., so as to reduce tailing Fringe vortex shedding frequency, easy processing, and the effect of reducing motor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The bionic impeller in this example is an improvement based on the prototype impeller, and the parameters of the prototype impeller are listed in Table 1:

[0023] Structural parameters symbol size Impeller inner diameter D 1 216mm Impeller outer diameter D 2 252mm Impeller width B 136mm number of blades Z 60 blade thickness d 0.4mm Import mounting angle β 1 72° outlet mounting angle β 2 168° blade curvature radius R 13.6mm

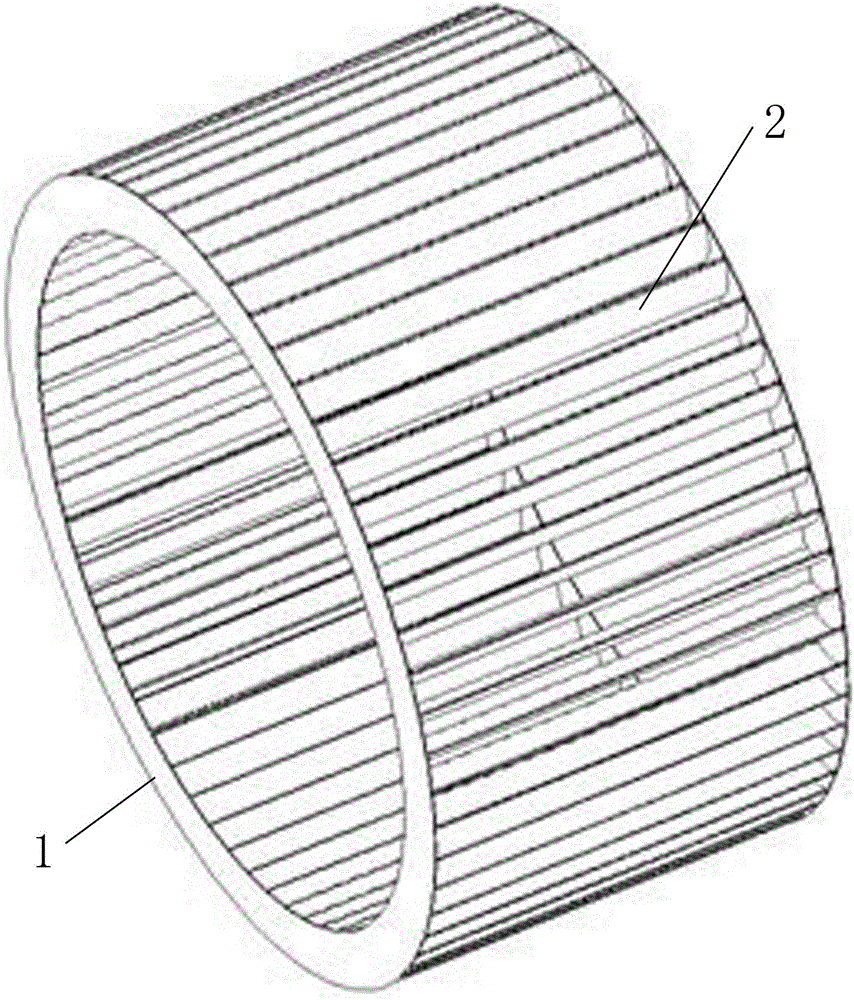

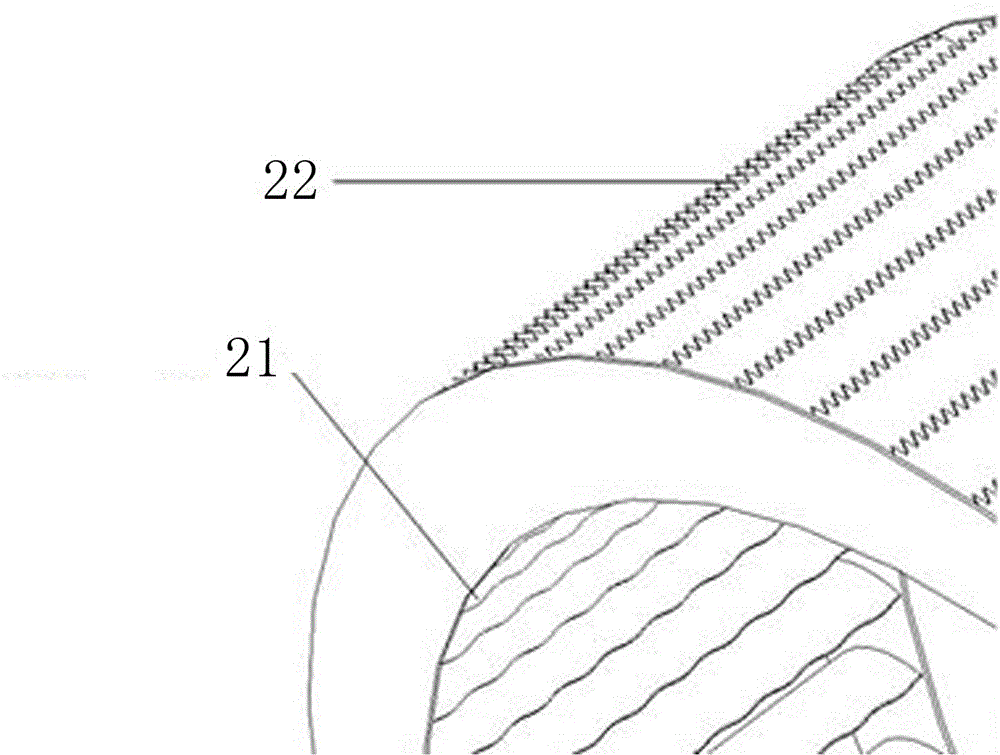

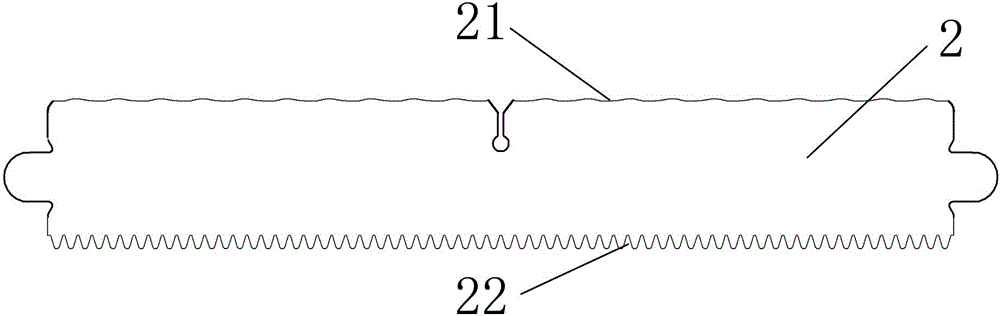

[0024] see Figure 1-6 , this embodiment includes two sets of annular end surfaces and blades, and blades are uniformly connected between the two sets of annular end surfaces. The blades in this embodiment are bionic blades, and the impeller blades are uniformly arranged with a single type of bionic blades. The side is the front edge of the wave structure, and the side facing the impeller range hood is the trailing edge of the sawtooth structure:

[0025] The leadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com