Large-scale and high-intensity rivet connection pair and manufacturing method thereof

A technology of rivet connection and super-large size, applied in other manufacturing equipment/tools, rivets, manufacturing tools, etc., can solve the problem of not meeting earthquake resistance and anti-loosening, and achieve the effect of saving materials and improving fatigue resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

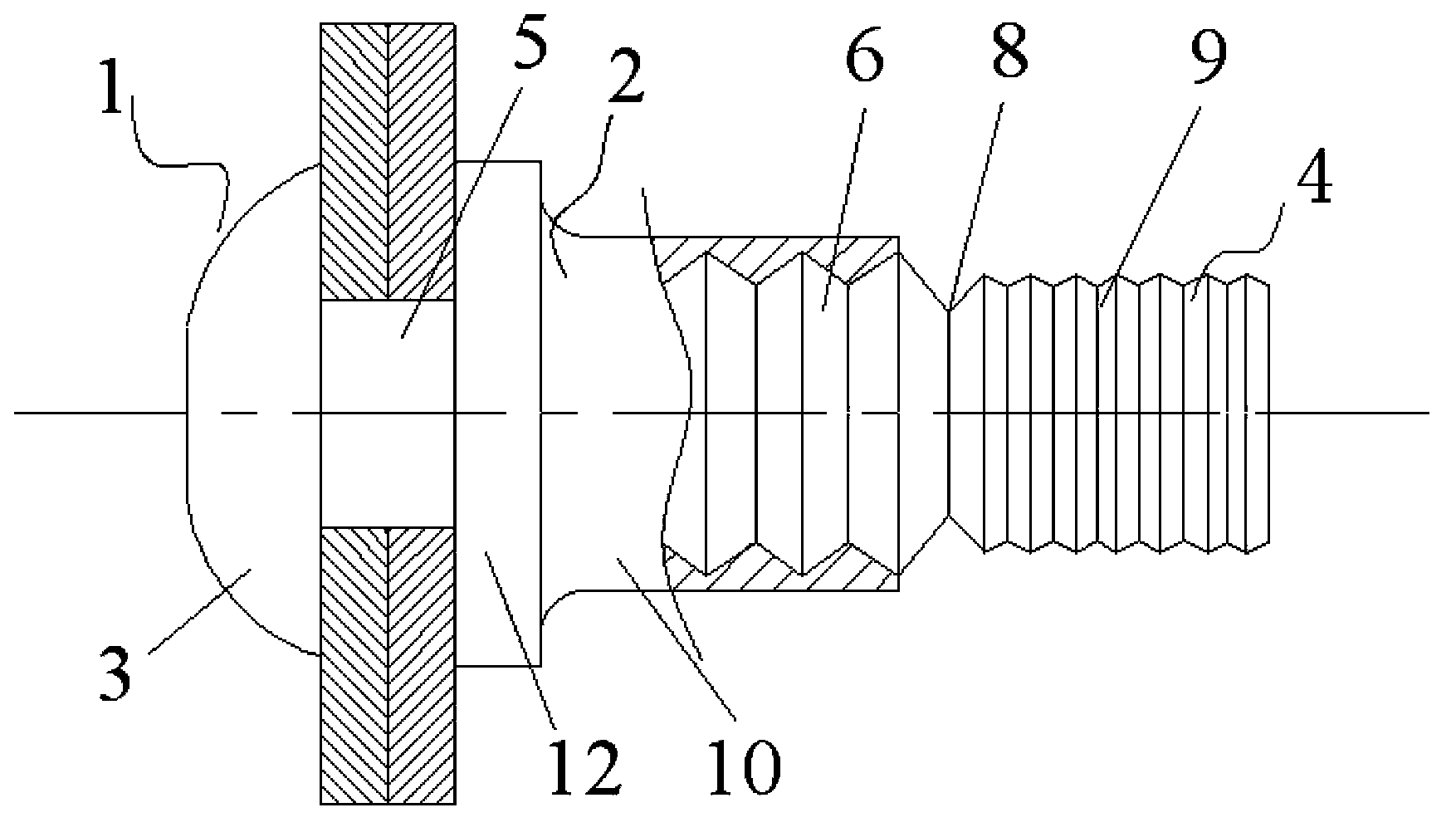

[0078] The present invention will be described in detail below in conjunction with specific examples.

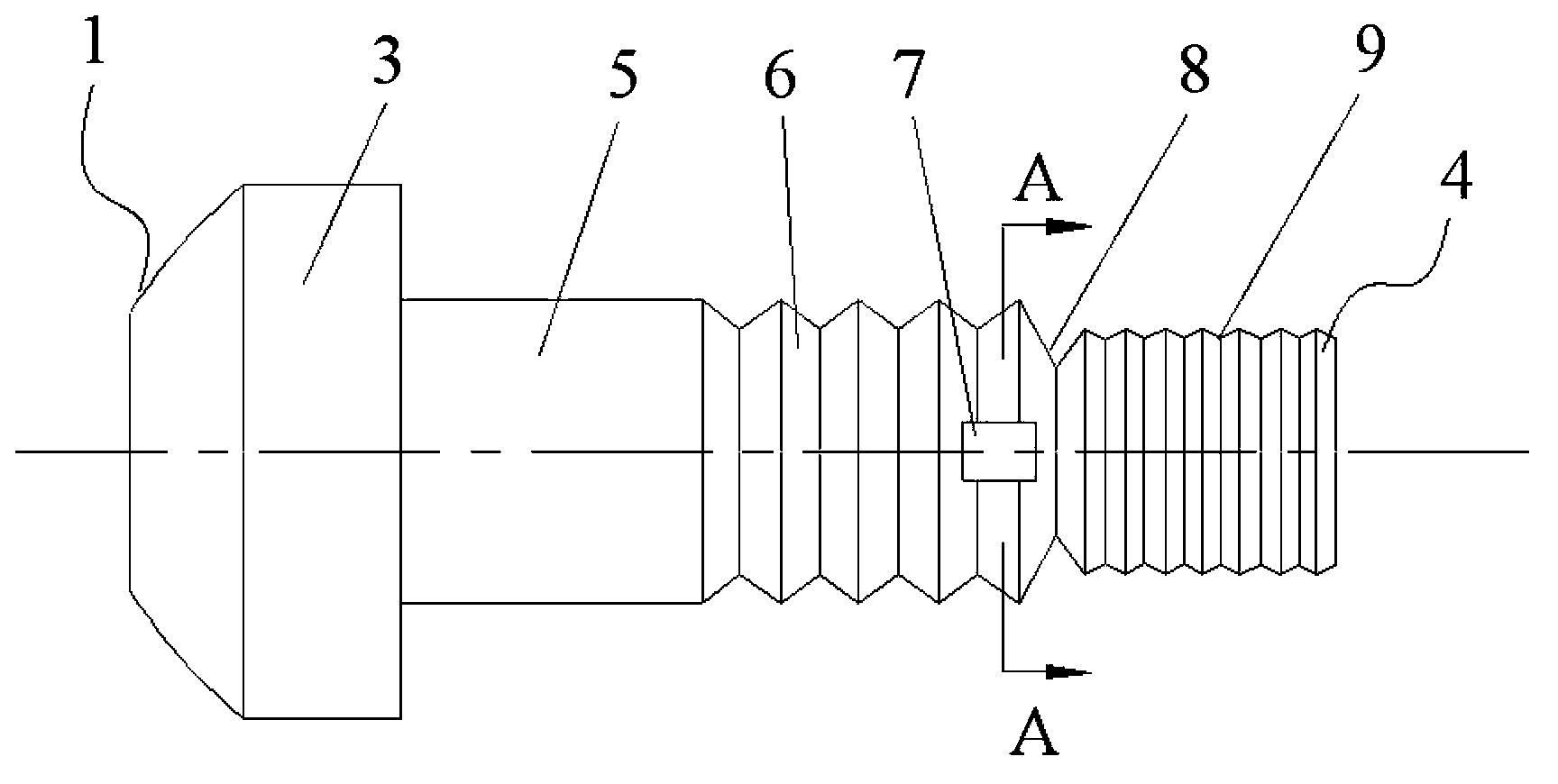

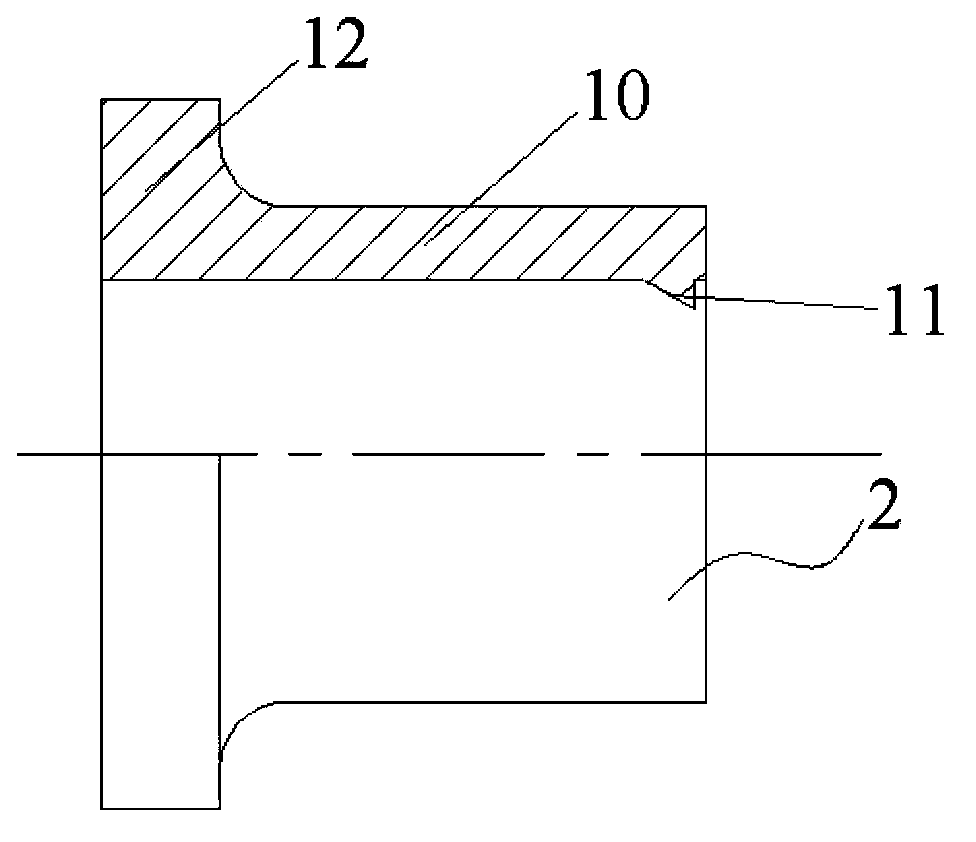

[0079] The manufacturing method of the super-large-sized high-strength rivet connection pair in this embodiment includes manufacturing rivets and manufacturing rivet sleeves, and the specific steps are as follows:

[0080] 1. Manufacture rivets

[0081] 1. Material selection and cutting

[0082] In this embodiment, medium-carbon alloy steel 40CrMnMo is selected as the material for manufacturing rivets, and the material is cut off according to the process requirements, and the outer circle is ground to remove surface metallurgical defects;

[0083] In this embodiment, medium carbon alloy steel 40Cr Ni Mo or 42Cr Mo can also be used as the material for manufacturing rivets;

[0084] 2. Warm upsetting the rivet material into a rivet blank with nail head and shaft

[0085] Upset the medium carbon alloy steel 40CrMnMo by warm upsetting to form a rivet blank with a nail head 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com