Spherical grid-structured top cover for low temperature liquefied gas and low temperature natural gas storage tanks

A grid structure and liquefied gas technology, applied in the container discharge method, gas/liquid distribution and storage, container filling method, etc., can solve the problems of unreasonable structural materials, loose surrounding material arrangement, and dense material in the middle, etc. Achieve the effect of uniform material arrangement, strong anti-uneven load capacity, and small cross-section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

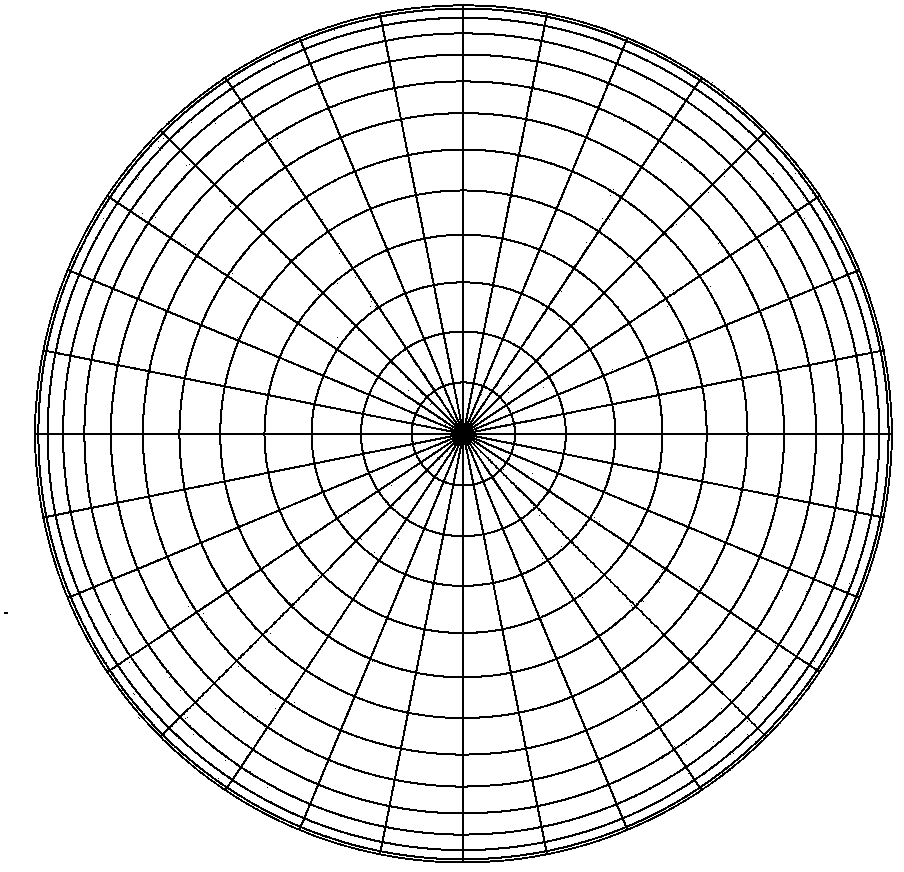

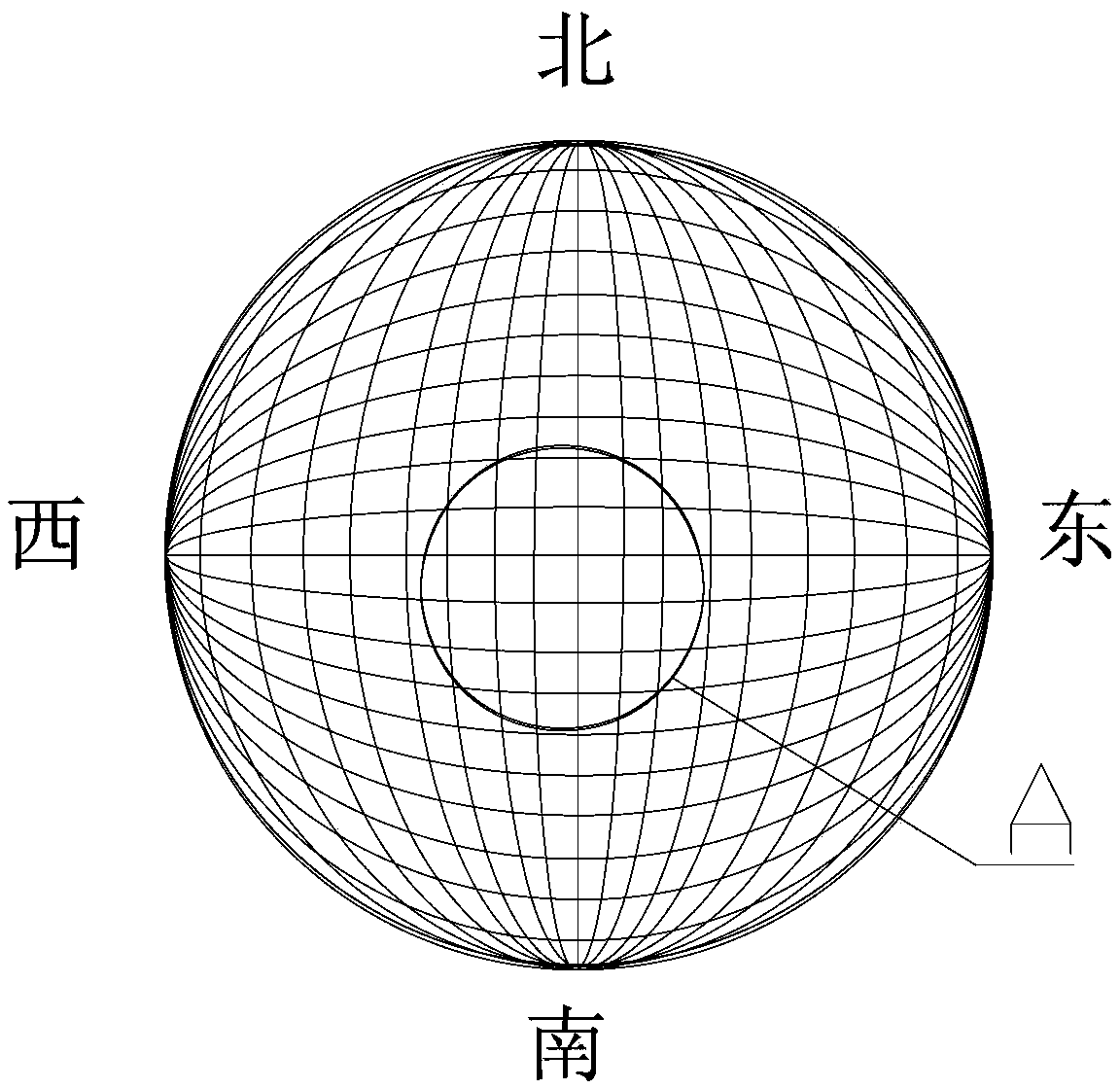

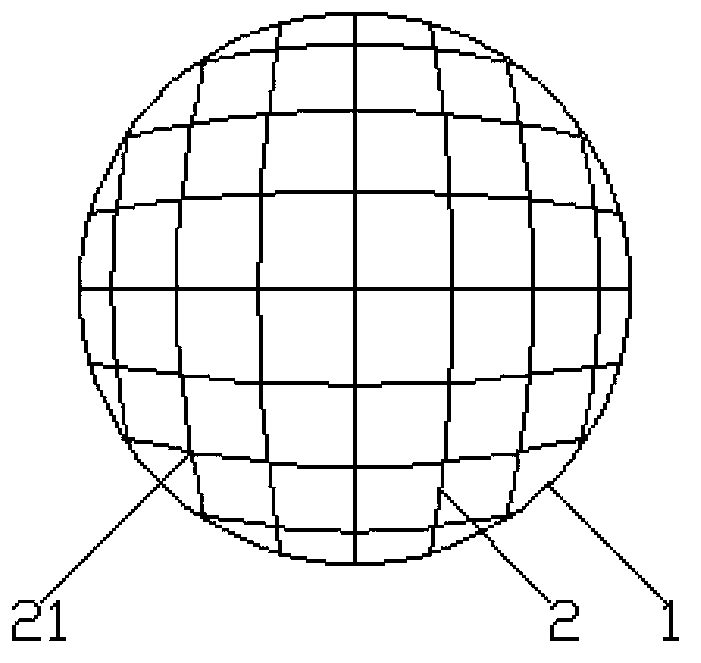

[0018] Such as Figure 2~3 Shown, a spherical grid structure top cover for low-temperature liquefied gas and low-temperature natural gas storage tanks, the top cover is installed on the top of the cylindrical storage tank, including a side ring beam 1, a reticulated shell connected to the side ring beam 2 and the skin installed on the reticulated shell. The reticulated shell 2 is a spherical two-way warp grid structure, which is welded by two-way warp arc mesh rods with through-type rigid joints, and each warp arc mesh rod The radius of curvature is the same spherical radius, which can be adapted to bear the uneven load and concentrated load of more than 100 tons on the top surface under the low temperature condition of -46~-164℃. A piece of A can be intercepted in the equator or temperate zone on the spherical surface of the two-way warp ball as the mesh shell of the spherical mesh structure of the present invention, such as figure 2 Shown.

[0019] The mesh poles are made of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com