Analysis method for engine crankshaft system torsional vibration

An analysis method and engine technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problem of not considering the influence of dual-mass flywheel on the crankshaft system, and achieve the effect of optimized design and accurate analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

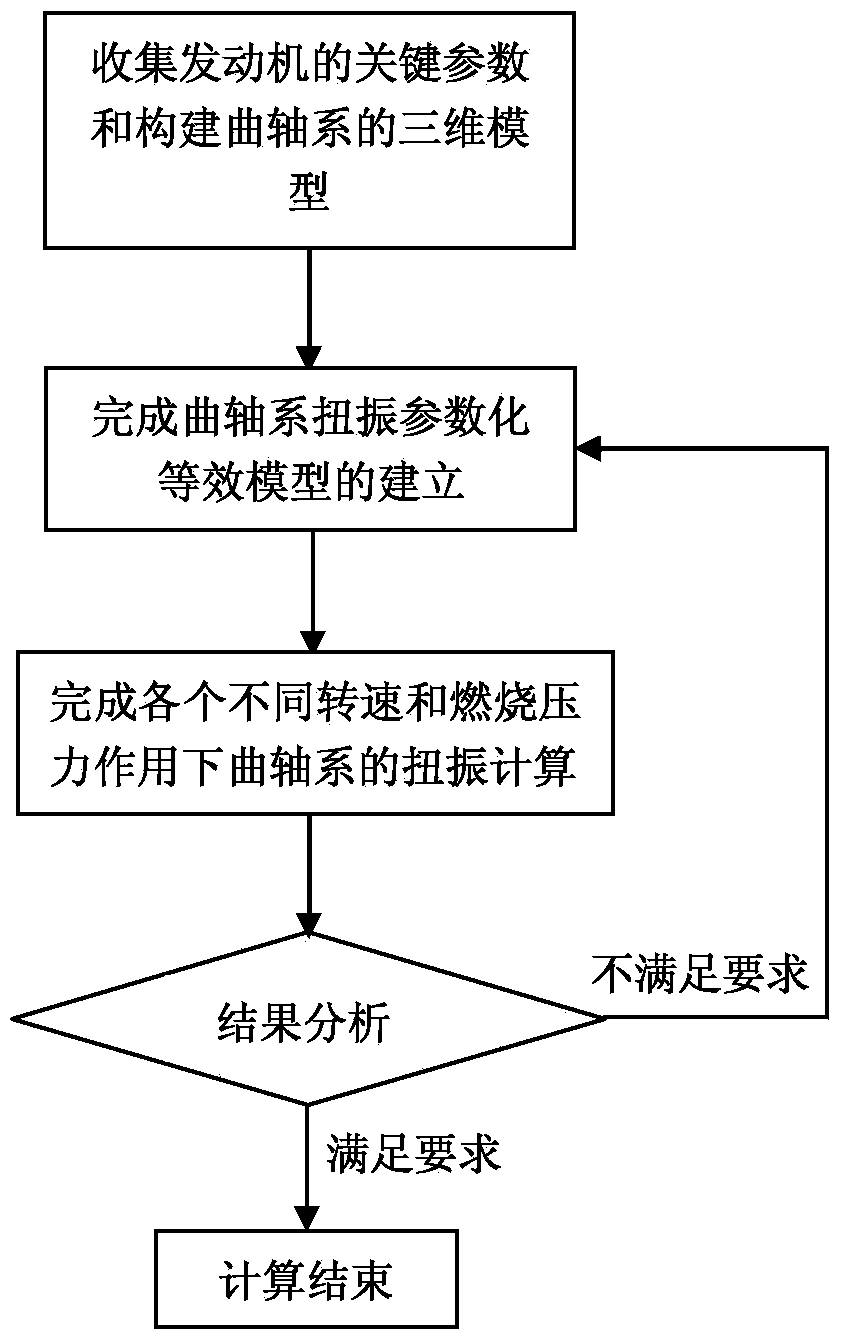

[0029] Such as figure 1 As shown, an engine crankshaft system torsional vibration analysis method includes the following steps:

[0030] (1) Collect the key parameters of the engine, including: the number of cylinders of the engine, the arrangement, the stroke size, the number of strokes, the length of the connecting rod, the quality of the piston assembly, and the combustion pressure in the next cycle at each speed; construct a three-dimensional model of the crankshaft system, 3D models including crankshaft, shock absorber and flywheel;

[0031] (2) Establish the torsional vibration parameterized equivalent model of the engine crankshaft system in Excite Designer;

[0032] Since the crankshaft system of the engine includes three components, the crankshaft, the shock absorber and the flywheel, the torsional vibration parameterized equivalent m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com