An ultra-thin planar transformer skeleton

A flat transformer, skeleton technology, applied in the direction of transformer/inductor coil/winding/connection etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

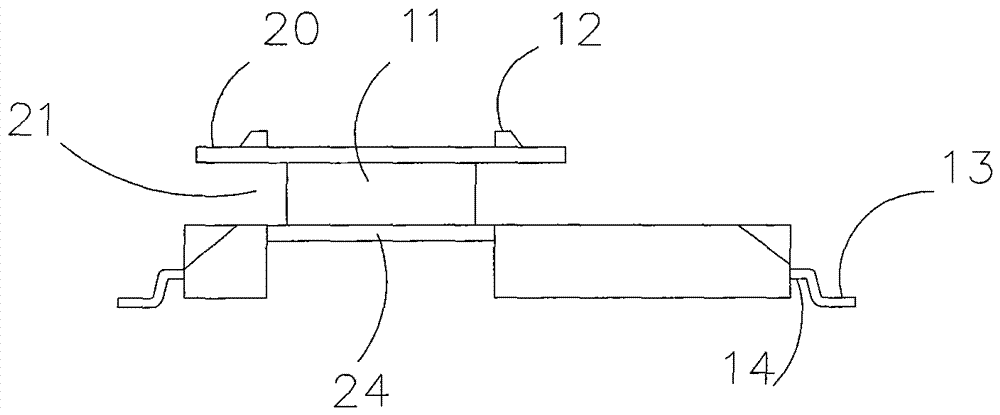

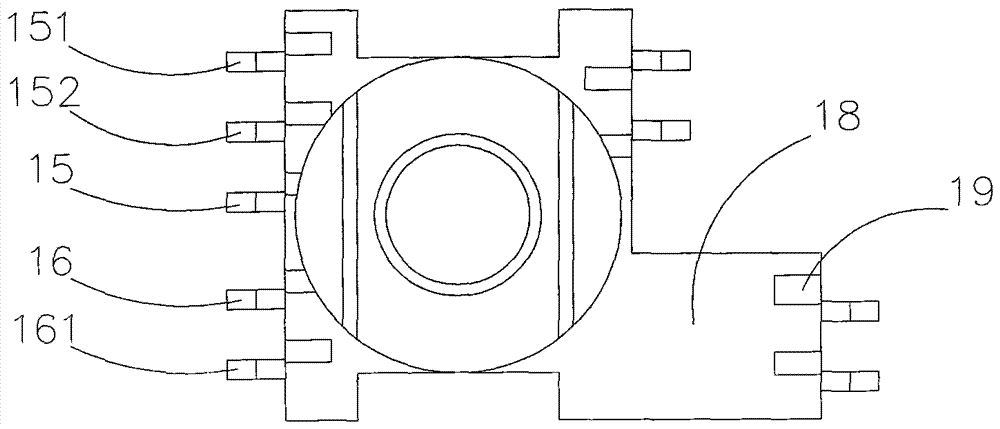

[0030] Such as Figure 1-3 As shown, an ultra-thin flat transformer bobbin includes a coil bobbin 24 and a winding post 11 arranged on the coil bobbin 24. A magnetic core assembly hole 23 is provided in the center of the winding post 11, and a transformer winding wrap guard leaf is arranged above it. 20. The transformer winding package guard leaf 20 and the coil bobbin 24 form a winding package limiting slot 21, and the primary side winding and the secondary side winding are wound in the winding package limiting slot 21, and the side of the coil bobbin 24 is connected with a secondary winding. The side extension bobbin 18, the other side of the coil bobbin 24 is provided with a set of primary side high-voltage winding surface mount pins 15, 151, 152 (wherein 152 is a center tap), a set of first primary side auxiliary winding surface mount pins 16, 161 A group of second primary side auxiliary winding surface mount pins 17, 171 are provided on the same side of the coil bobbin 24...

Embodiment 2

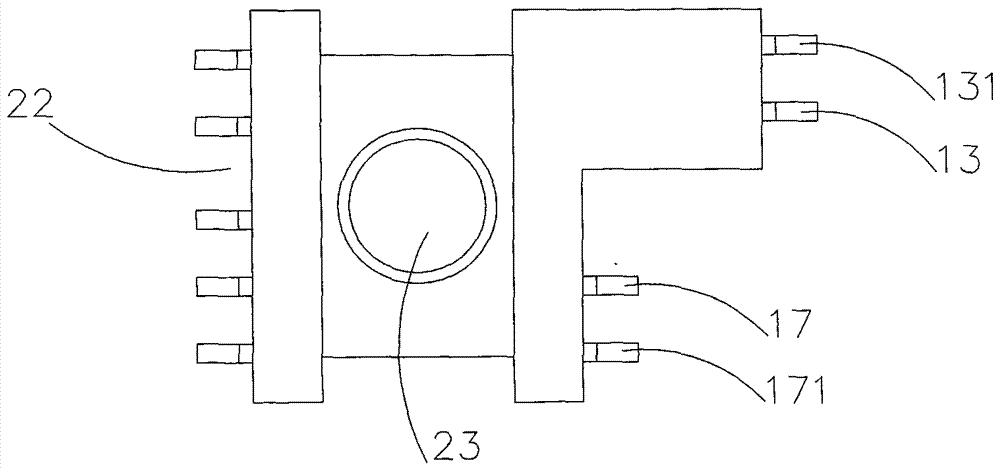

[0032] Such as Figure 4 As shown, except that the positions of the secondary-side extension frame 18 and the surface-mount pins 17 and 171 of the second primary-side auxiliary winding are exchanged, other structures are the same as those of the first embodiment.

Embodiment 3

[0034] Such as Figure 5 As shown, except that the positions of the surface-mount pins 15, 151, 152 of the primary-side high-voltage winding and the surface-mount pins 16, 161 of the first primary-side auxiliary winding are exchanged, other structures are the same as those of the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com