Lithium iron phosphate power battery management system and management method

A power battery and lithium iron phosphate technology, which is applied to battery circuit devices, current collectors, electric vehicles, etc., can solve problems such as poorer performance than single batteries, large estimation errors, and unreasonable energy management, and achieve enhanced management and control functions , good applicability and versatility, and the effect of simplifying the setting of charging parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the drawings and embodiments.

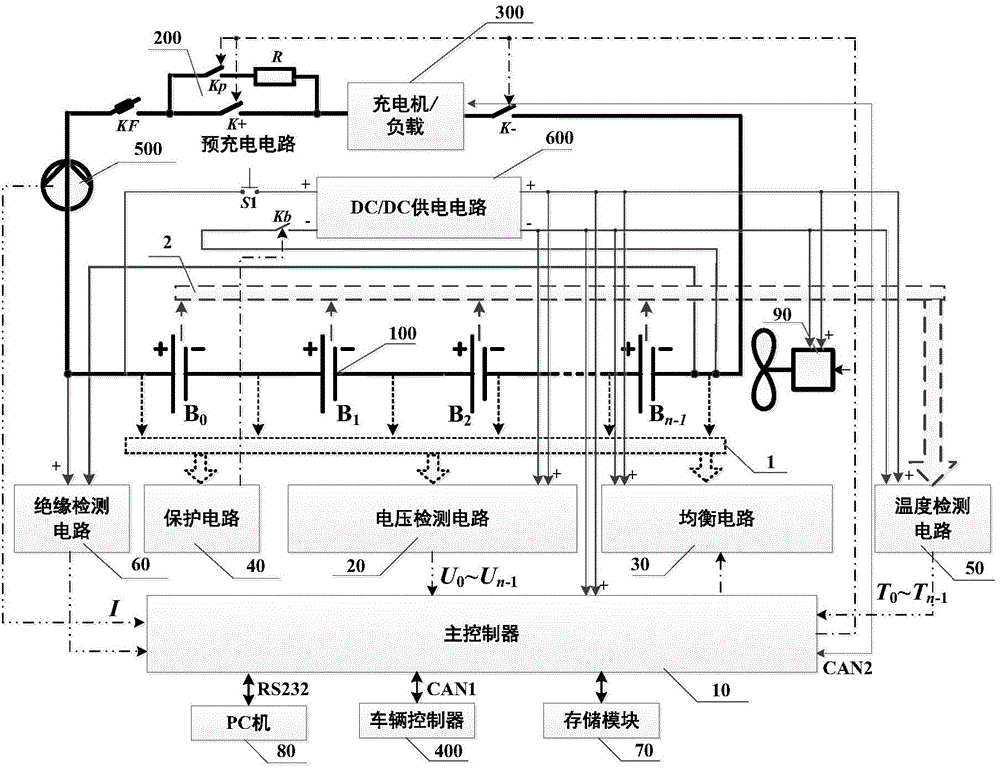

[0037] Such as figure 1 As shown, the battery management system includes a main controller 10, a voltage detection circuit 20, a temperature detection circuit 50, an insulation detection circuit 60, an equalization circuit 30, a protection circuit 40, a DC / DC power supply circuit 600, a precharge circuit 200, and a cooling fan 90 , Power battery pack 100, PC 80, vehicle controller 400 and storage module 70. It has the following functions: ①Battery cell voltage and total voltage detection; ②Battery pack charge and discharge current detection; ③Battery pack fault diagnosis and overcharge, overdischarge and equalization mandatory protection and temperature protection; ④Battery pack status (SOC , SOH, RUL) accurate estimation; ⑤Zero current switch fast equalization; ⑥Precharge; ⑦Battery pack insulation measurement; ⑧Battery pack operation and fault data recording; ⑨Commun...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com