Loudspeaker module and assembling method of loudspeaker module

A loudspeaker module and loudspeaker technology, applied in the direction of loudspeaker transducer fixation, microphone, sensor, etc., can solve the problems of loudspeaker ultrasonic machine damage, deformation of plastic shell, poor sealing of front and rear sound chambers, etc., and achieve a qualified rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

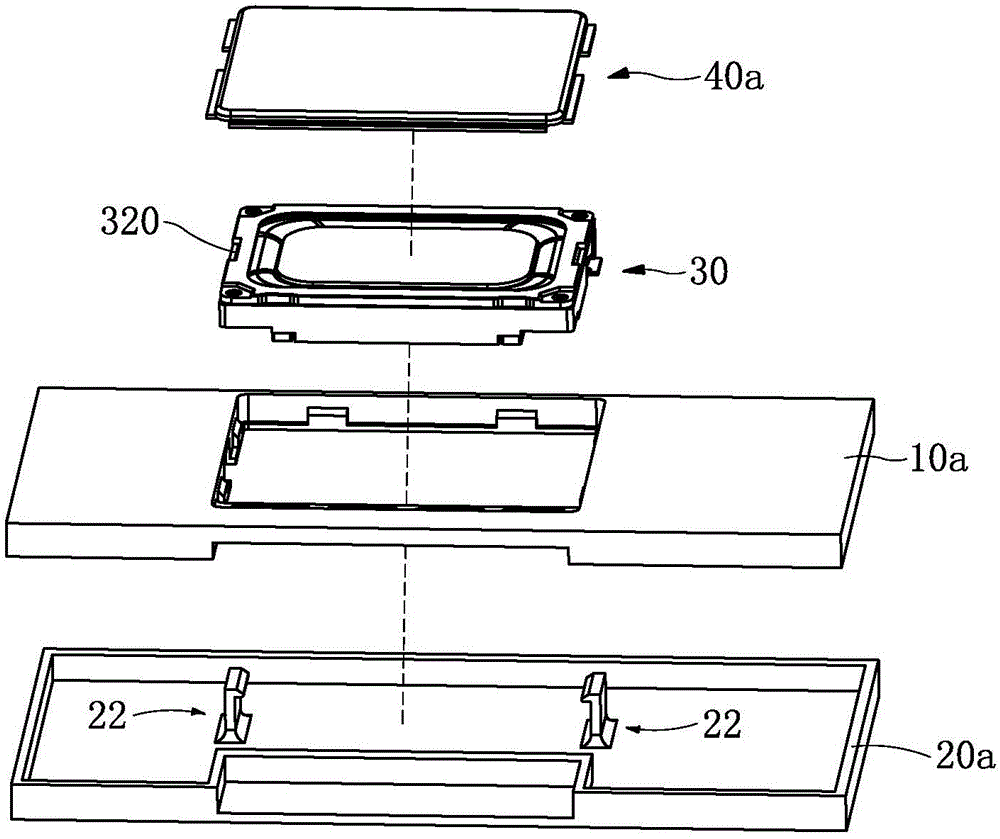

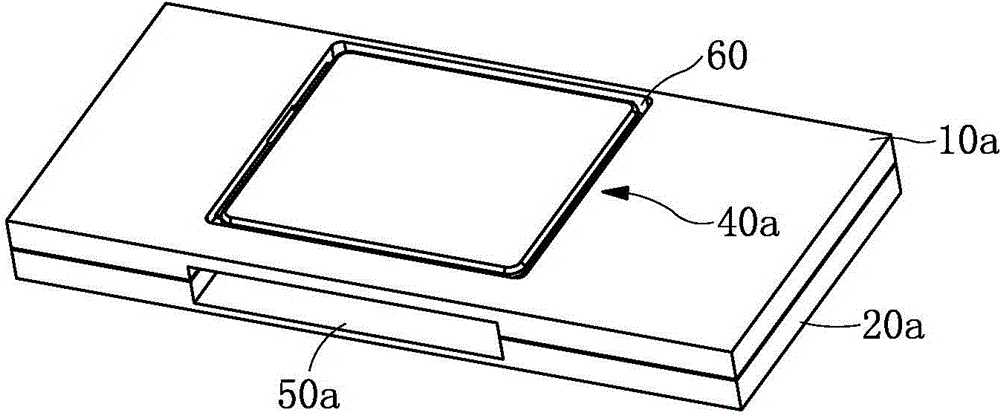

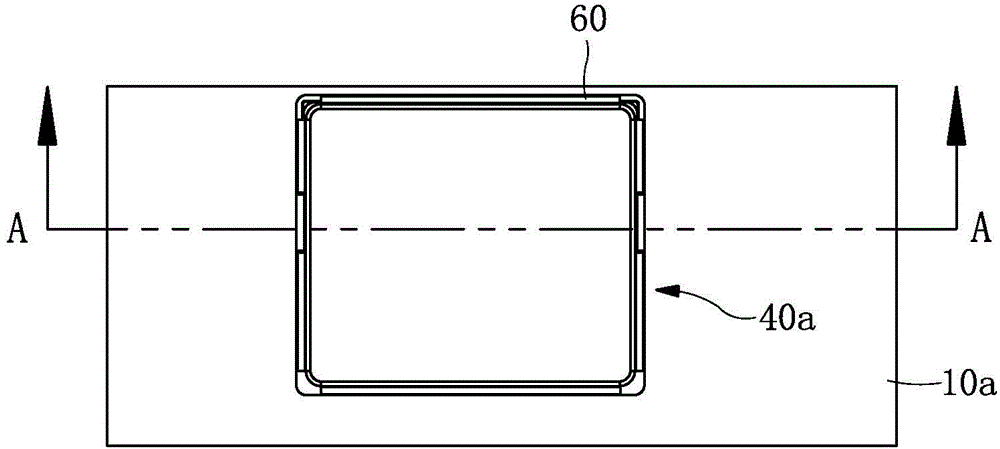

[0044] Such as figure 1 and figure 2Commonly shown, a loudspeaker module includes a third shell, a first shell 10a and a second shell 20a that are sequentially combined, wherein the third shell is a steel sheet 40a, the steel sheet 40a, the first shell The speaker unit 30 is housed in the space enclosed by the body 10a and the second casing 20a. The module has a side sound output structure, and the sound output hole 50a is located on the side of the speaker unit 30 and is jointly surrounded by the first casing 10a and the second casing 20a. First housing 10a, steel sheet 40a and loudspeaker unit 30 jointly surround the front acoustic cavity 70 of the module (such as Figure 4 As shown), the first housing 10a, the second housing 20a and the speaker unit 30 jointly form the rear acoustic cavity 72 of the module (as shown in FIG. Figure 4 shown). The first shell 10a and the second shell 20a are fixed and sealed by an ultrasonic welding process, and the steel sheet 40a and t...

Embodiment 2

[0051] Such as Figure 13 , Figure 14 and Figure 15 Commonly shown, this embodiment is basically the same as Embodiment 1, the difference is:

[0052] The space surrounded by the steel sheet 40b, the first casing 10b and the second casing 20b contains a speaker unit, the module is a positive sound output structure, and the sound outlet 50b is arranged in the middle of the steel sheet body 42b, and the sound output The hole 50b is located within the range of the orthographic projection of the speaker unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com