Corrosion-resistant steel for hold of coal carrying vessel or coal/ore carrying vessel

A corrosion-resistant steel and coal technology, applied in the field of steel, can solve the problems of different anti-corrosion mechanisms and the inability to directly switch to corrosion-resistant steel, etc., and achieve the effect of inhibiting corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] First, in order to determine the maximum pitting corrosion depth, the steel sheets shown in Table 1 were used to obtain examples according to the following procedures (this test method is referred to as corrosion test a).

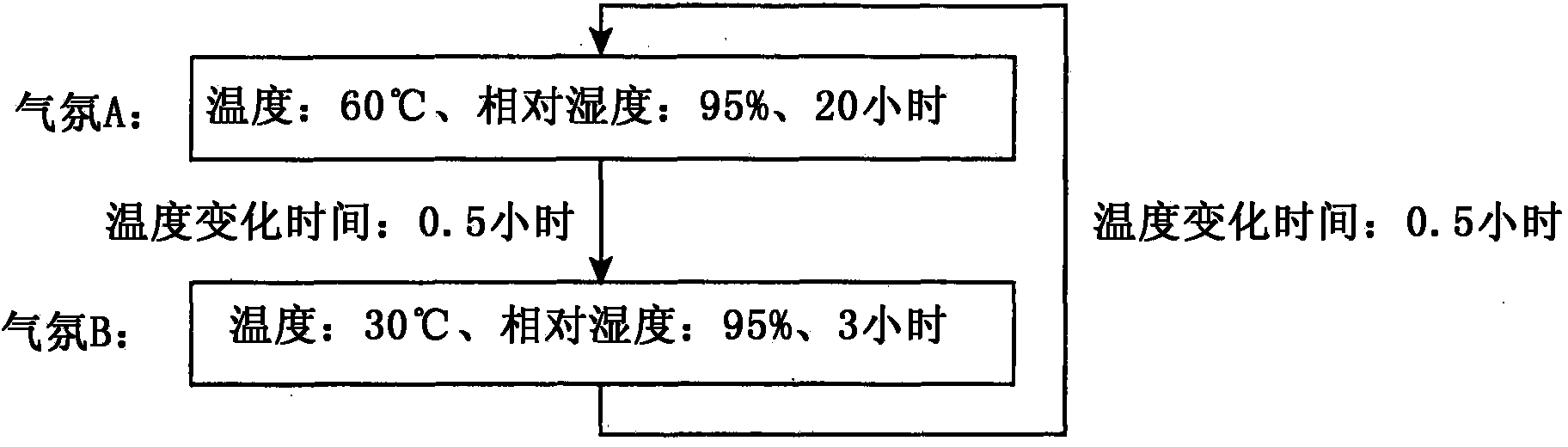

[0092] Cut 5mm from the steel plate with the composition shown in Table 1. t ×50mm W ×75mm L The surface of the test piece is shot blasting to remove the scale and oil content on the surface. Using this surface as a test surface, the corrosion resistance of the steel material after peeling of the coating film was evaluated. After coating the back and end surfaces with a silicon base adhesive tape, it is embedded in an acrylic cell, and 5g coal is spread on it, and passed through a temperature and humidity chamber) for 28 days of temperature and humidity cycle, the temperature and humidity cycle is figure 1 Atmosphere A shown (temperature: 60°C, humidity: 95%, 20 hours) Atmosphere B (temperature: 30°C, humidity: 95%, 3 hours) has a temperature and humid...

Embodiment 2

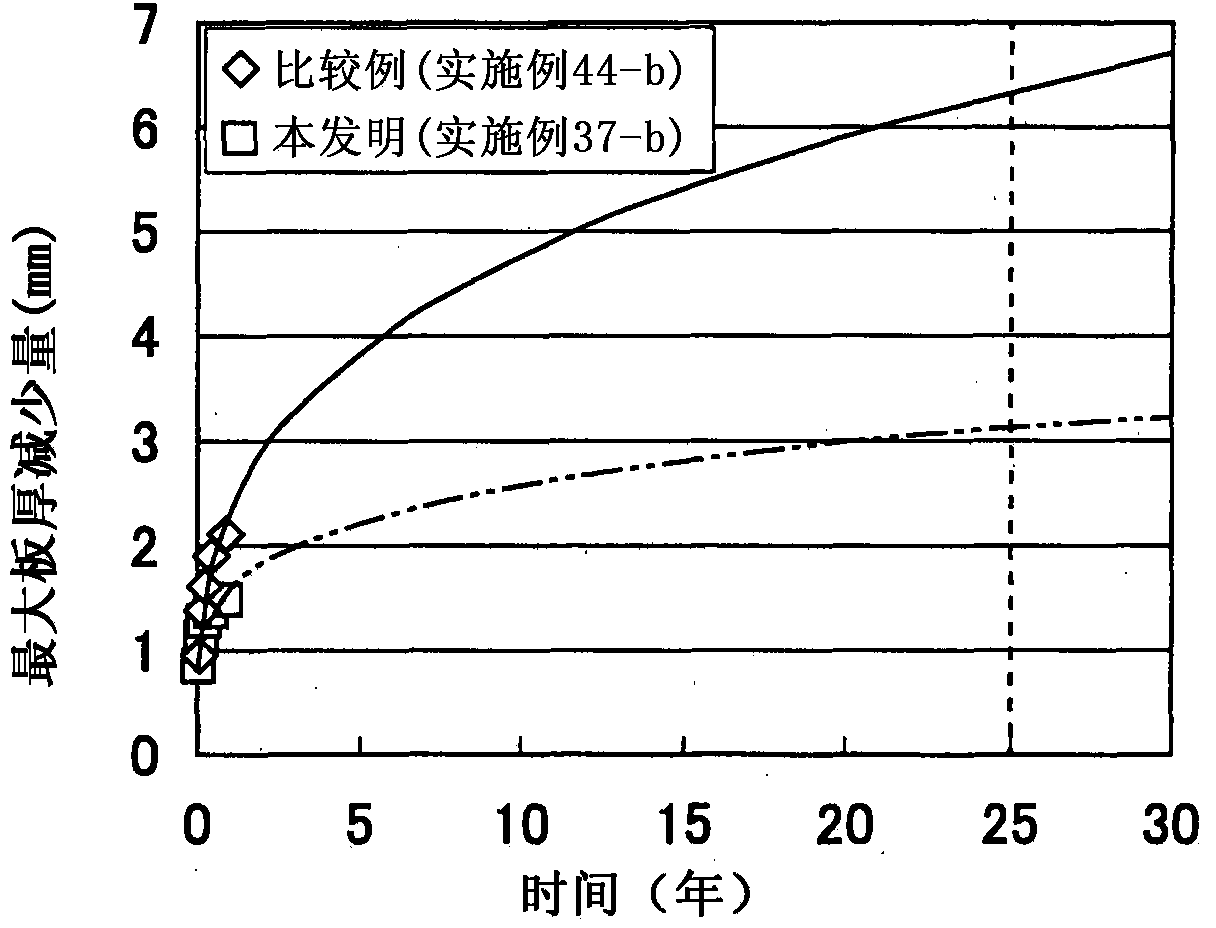

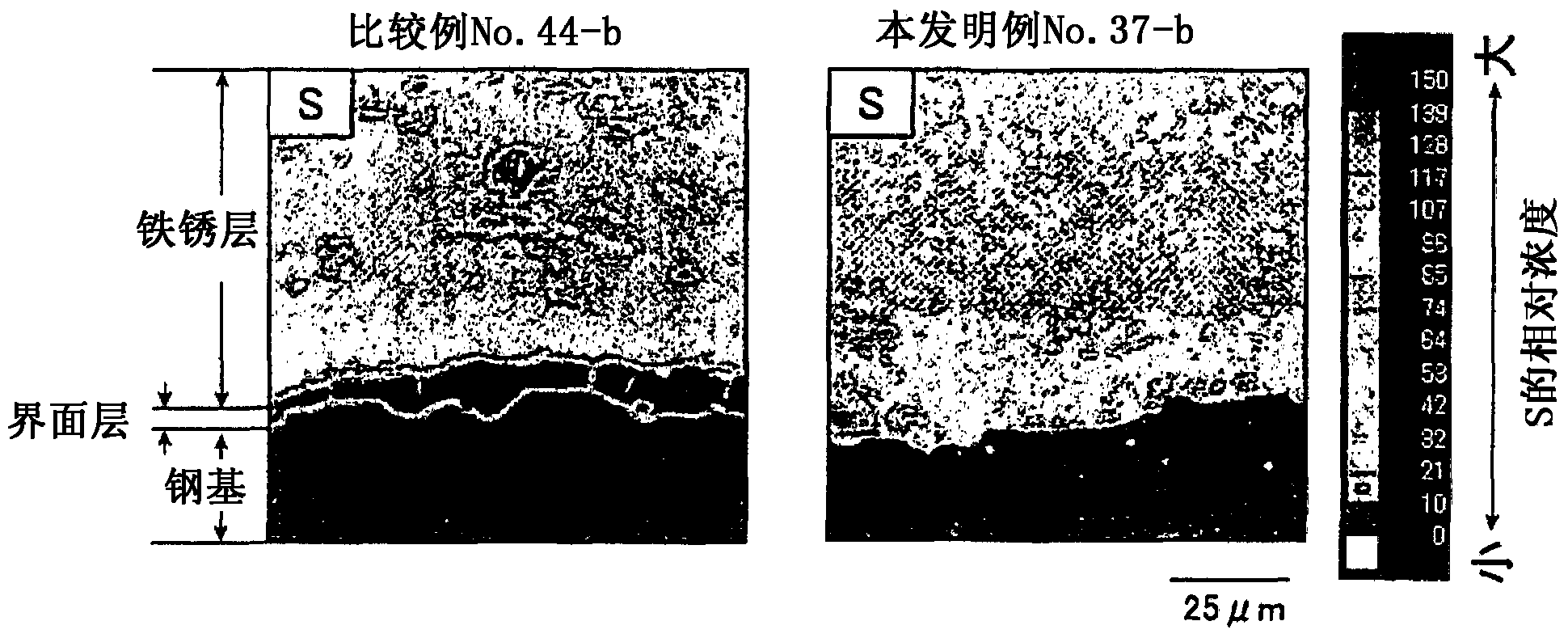

[0095] Next, an example for estimating the maximum plate thickness reduction after 25 years is shown. As in Example 1, cut 5mm from the steel plate shown in Table 1. t ×50mm W ×75mm L Test piece. The surface of the test piece was sandblasted to remove oxide scale and oil on the surface, and the surface was used as a test surface to evaluate the corrosion resistance of the steel material after peeling of the coating film. After coating the back and end faces with silicone sealant, insert them into acrylic jigs, spread 5g coal on them, and perform temperature and humidity for 28, 56, 84, 168, 336 days with a low temperature, constant temperature and humidity chamber Cycle, the temperature and humidity cycle is figure 1 Atmosphere A shown (temperature: 60°C, humidity: 95%, 20 hours) Atmosphere B (temperature: 30°C, humidity: 95%, 3 hours) has a temperature and humidity cycle with a change time of 0.5 hours (this test method is referred to as corrosion test b).

[0096] It should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com