Electric traction rack truck

A technology of rail trucks and electric traction, which is applied in the fields of electronics, hydraulics and machinery, can solve the problems of low transportation efficiency, low traction force and low efficiency, and achieve the effect of improving transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing:

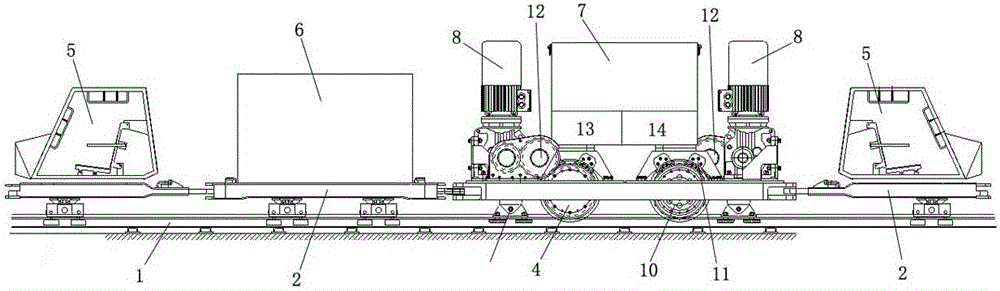

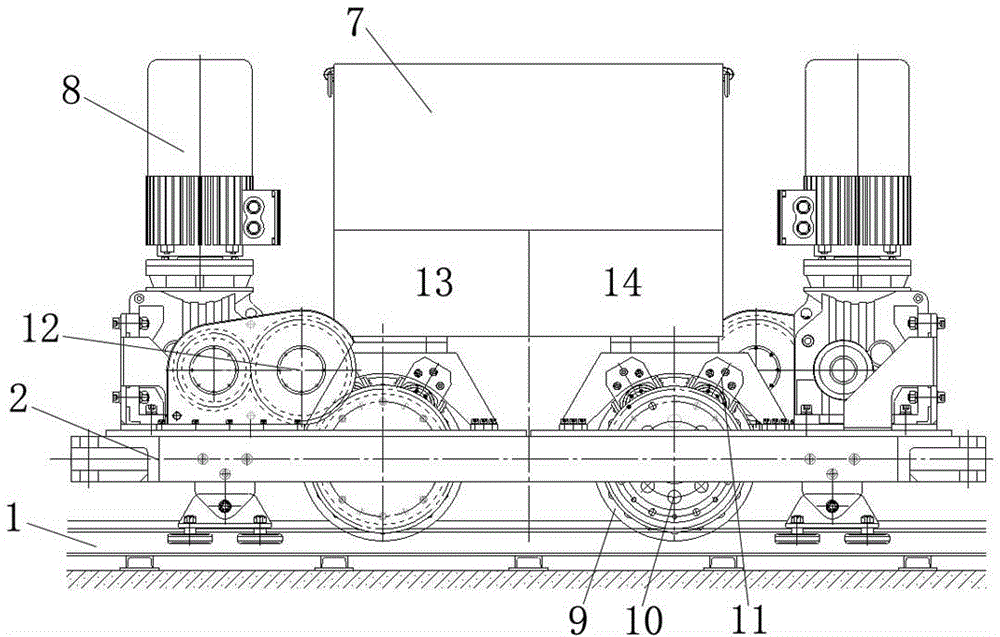

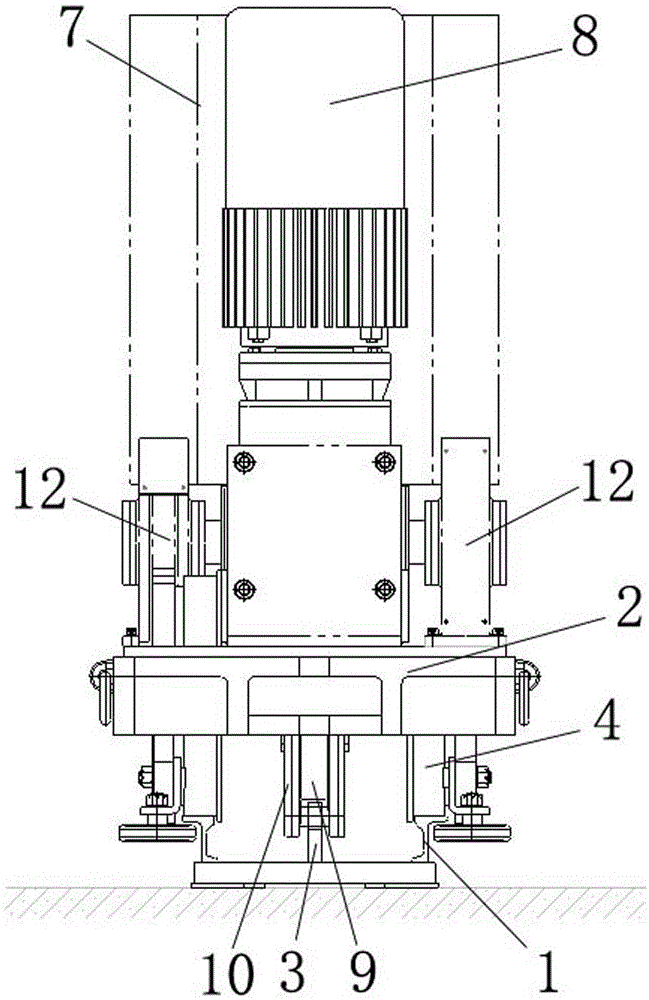

[0030] Such as Figure 1-5As shown, an electric traction rack rail car includes two straight rails 1 and at least four frames 2 hingedly connected to each other. A rack 3 is arranged in the middle of the two straight rails 1 . Two pairs of adhesive wheels 4 clamped on the straight rail 1 are all installed, and a cockpit 5 is provided on the two frames 2 at the beginning and the end, and an explosion-proof diesel generator 6 is installed on one of the frames 2 in the middle. An electric control box 7 and two explosion-proof frequency conversion motors 8 are installed on another frame 2 located in the middle. The two explosion-proof frequency conversion motors 8 are placed at both ends of the frame 2. 8, and the two pairs of adhesive wheels 4 installed on the frame 2 of this section correspond to two explosion-proof variable frequency motors 8 respectively, and pin gears 9 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com