Baking system for permanent magnet direct driving mechanism, control method and gate opening and closing mechanism

A permanent magnet direct drive, braking system technology, applied in the control of mechanical energy, fluid pressure actuation system safety, brake actuators, etc. The effect of reducing the probability of accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

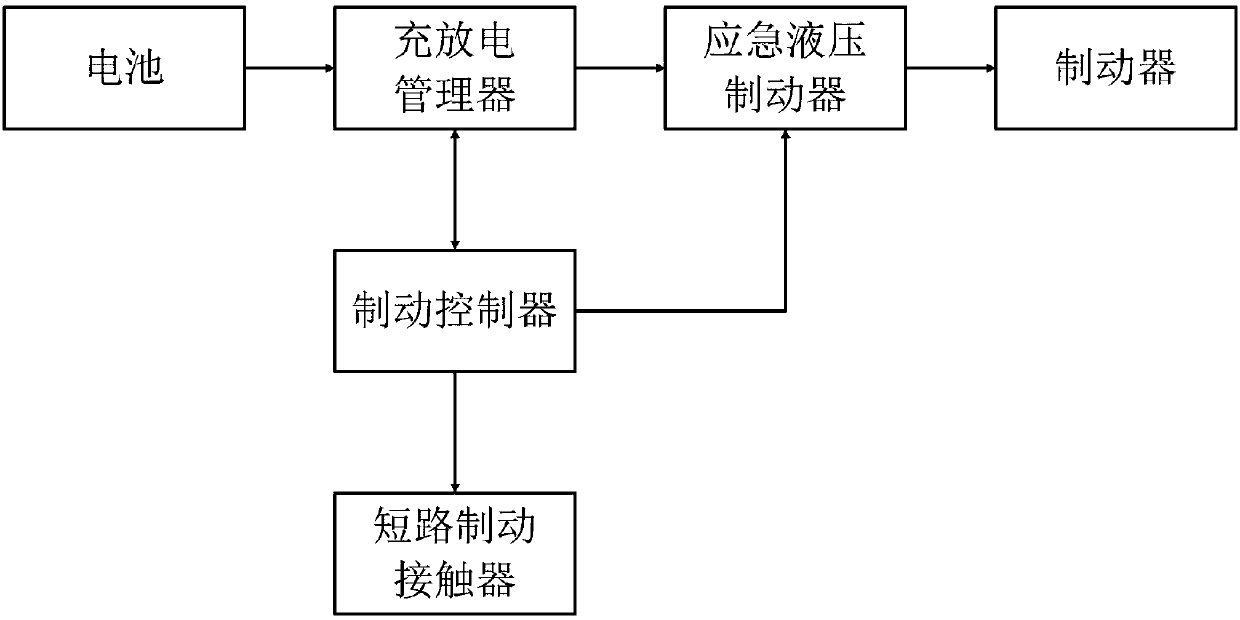

[0037] Such as figure 1 Shown is the functional block diagram of the braking system of the present invention: the braking system for permanent magnet direct drive mechanism provided by the present invention includes a brake, a brake controller, a battery, an emergency hydraulic brake, a short-circuit braking contact controller, charge and discharge manager and speed sensor; the battery is connected to and supplies power to the emergency hydraulic brake; the AC hydraulic station is connected to the brake to provide additional braking power for the brake when the power supply of the brake fails; the brake controller is used to Send a control signal to the AC hydraulic station; the contact of the short-circuit brake contactor is connected to the input end of the permanent magnet synchronous motor in the permanent magnet direct drive mechanism, and the control end of the short-circuit brake contactor is connected to the brake controller and receives The control signal of the brake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com