Telescopic cylinder guide rail in automobile crane

A telescopic oil cylinder and truck crane technology, applied in cranes and other directions, can solve the problems of increased overall investment, large workshop space, and difficult processing, and achieve the effects of less processing difficulty, good strength and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

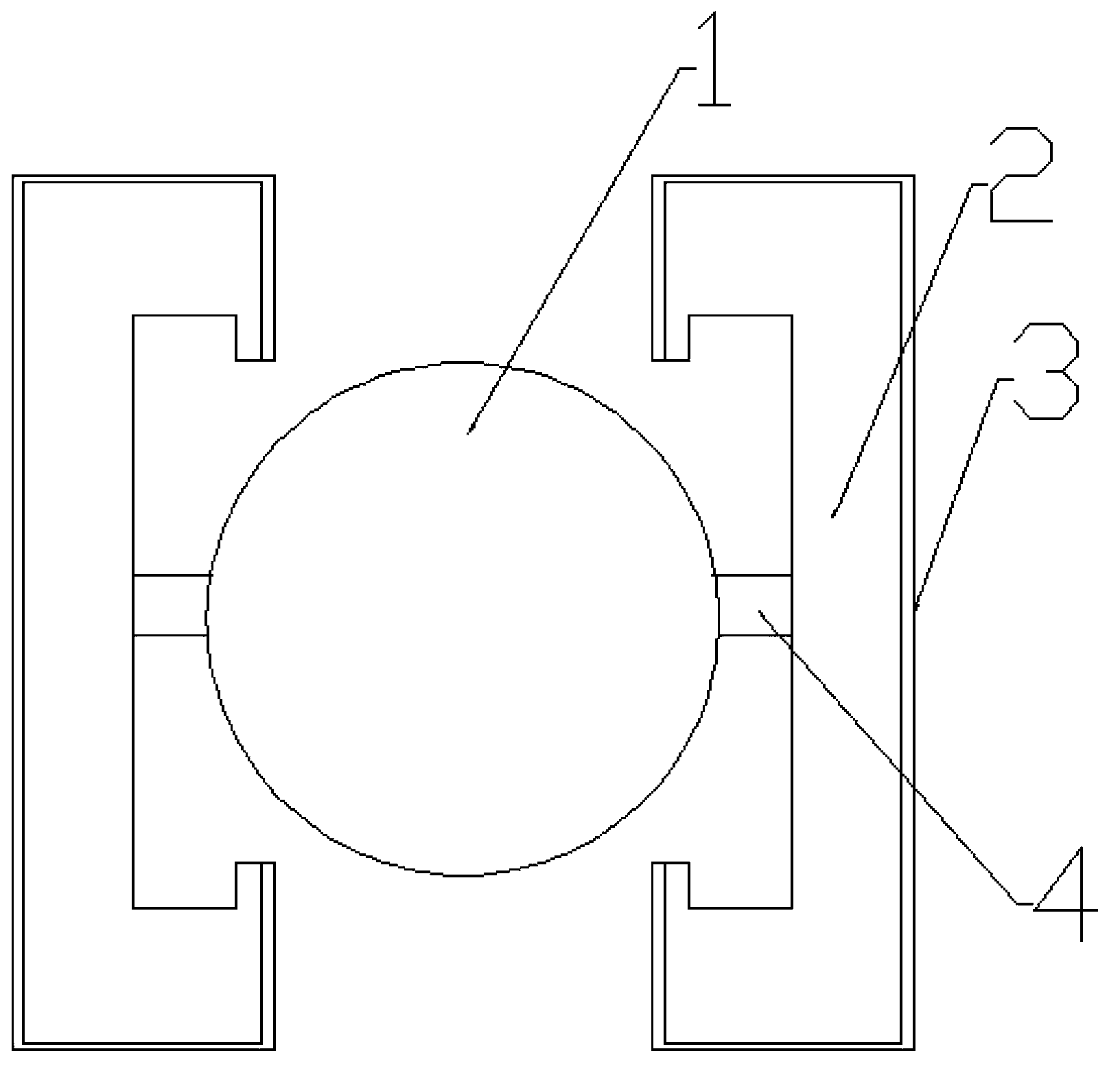

[0012] Such as figure 1 As shown, the present invention provides a telescopic oil cylinder guide rail of a car crane, which is arranged on the lifting arm of the car crane, and includes a guide rail 2 body, the guide rail 2 body is fixedly arranged on the oil cylinder 1, and the guide rail 2 body is connected to the The axis of the oil cylinder 1 is arranged in parallel, and the number of the guide rail 2 bodies is two, which are mirror-symmetrically arranged on both sides of the oil cylinder 1. The body of the guide rail 2 is C-like, and the body of the guide rail 2 is A self-lubricating guide plate 3 is arranged on the outer surface, and the self-lubricating guide plate 3 is connected with the lifting arm of the automobile crane.

[0013] The body of the guide rail 2 is a sheet metal structure bent into a C-like shape. C-shaped sheet metal structure, light in weight, less difficult to process, small space occupied by machine tools, low cost, and good strength.

[0014] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com