A clamping method for anodic oxidation of large wallboard parts

A large-scale wallboard and anodizing technology, which is applied in the direction of anodizing, can solve the problems of falling parts, easily scratching the substrate of parts, and large printing of fixtures, etc., and achieve the effect of improving electrical conductivity, optimizing electrical conductivity, and facilitating fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

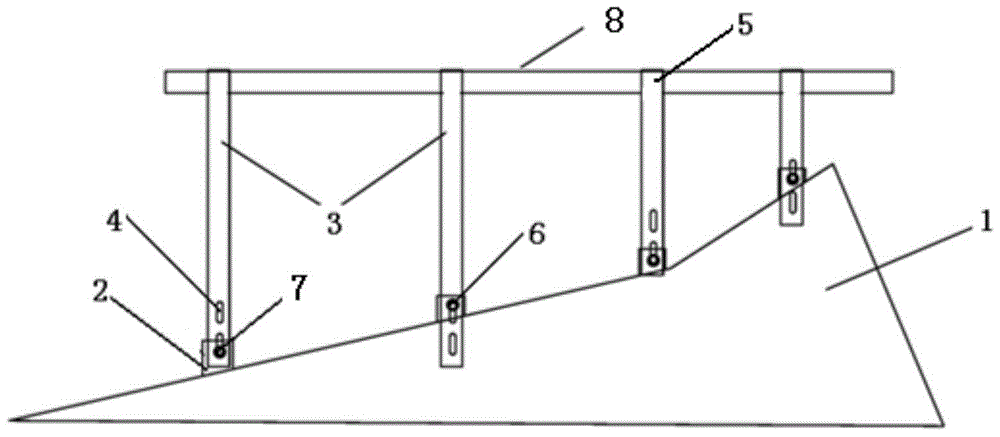

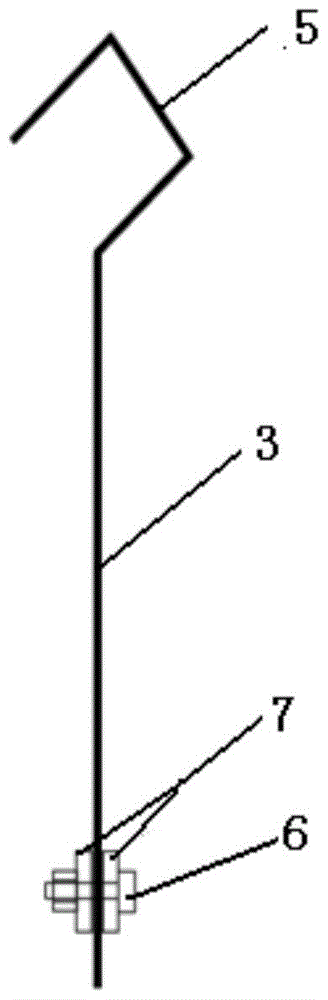

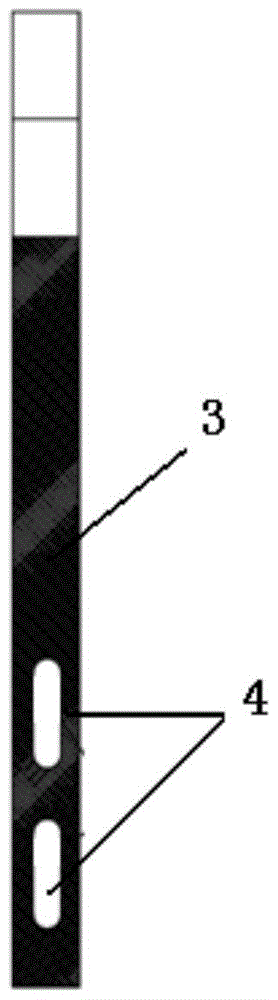

[0010] Referring to the attached figure, part 1 is a wall panel of a large aircraft wing, which needs to be anodized during the manufacturing process. The wall panel part is more than thirteen meters long and weighs more than 200 kilograms. The size and weight of the wing wall plate are provided with four clamping lugs 2 on the hanging side of the part, and each clamping lug is provided with a circular connection hole; the hanging fixture is composed of four clamping lugs matching The metal hanging belt 3 is composed of 2024T3 aluminum alloy plates with a thickness of 6mm and a width of 70mm. The upper end of each metal hanging belt is provided with an elbow hook 5, and the other end is provided with an oblong limit hole. 4. The metal sling is made of wide aluminum plate to ensure that it can bear the weight of the wall parts. At the same time, the contact area between the metal sling 3 and the part 1 is increased to facilitate the smooth passage of the current, while the conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com