A combined hanging device for a double-deck ring header

An annular header and hanging device technology, applied in the chemical industry, can solve the problems of unsatisfactory support effect, uncompact structure, and many consumables, etc., and achieve the effect of reasonable and reliable force, safe structure, and reduction of overall gravity load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

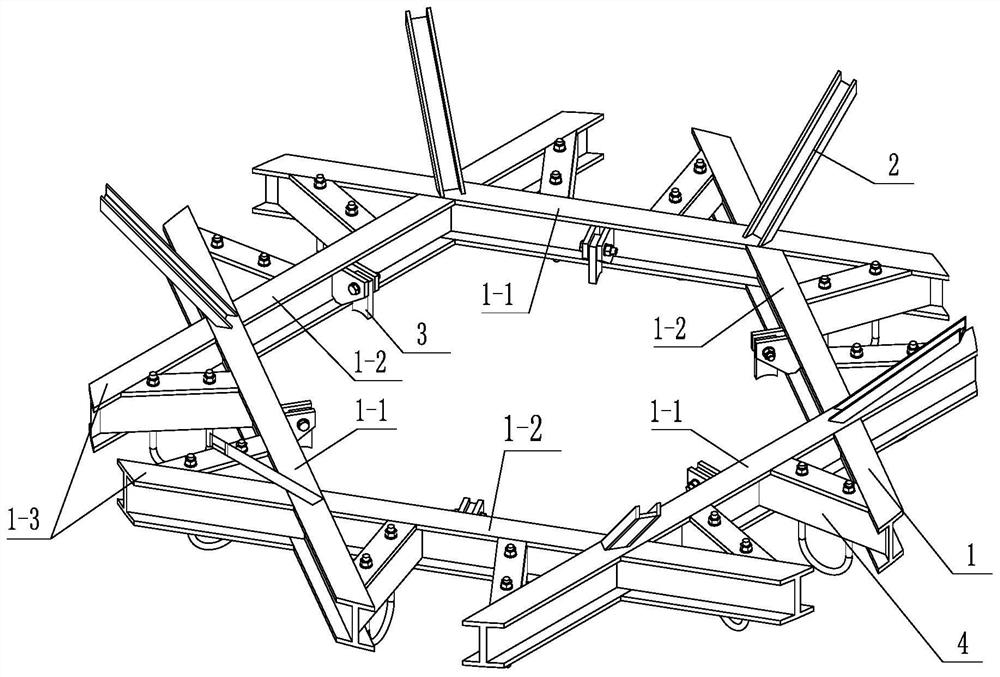

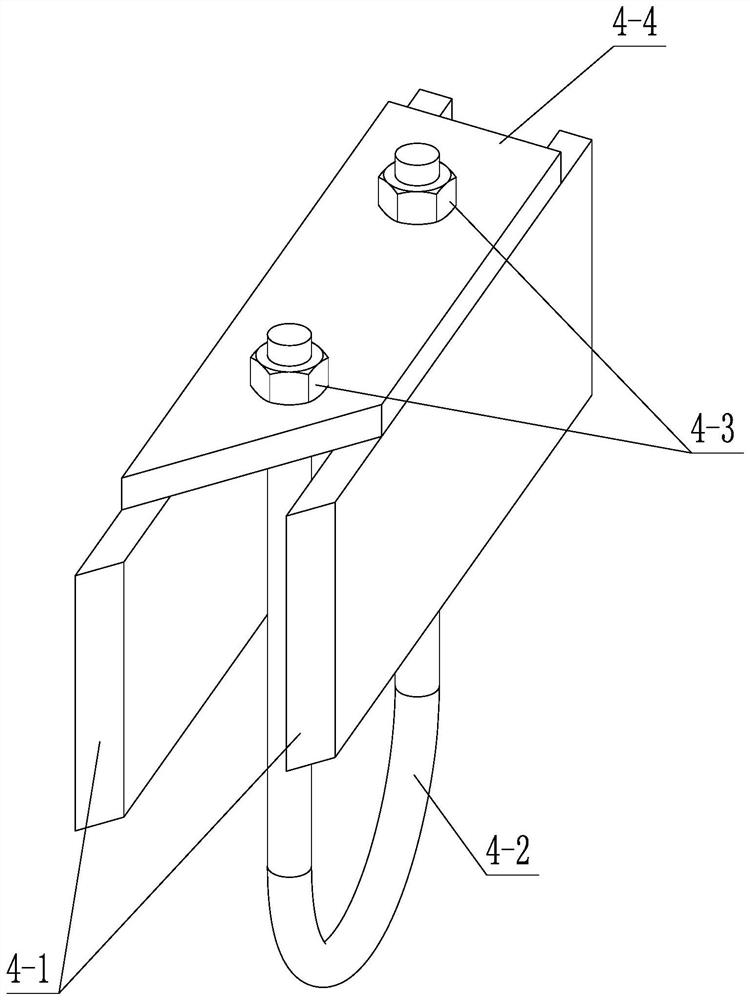

[0025] Specific implementation mode one: combine figure 1 and Figure 4 Describe this embodiment mode, a kind of combined suspension device for double-layer annular header of this embodiment mode, it comprises hexagonal star structure beam (1), six oblique tie bars (2), six cantilever lifting lugs of inner ring header component (3) and twelve outer ring header hanging beam components (4), the hexagonal star structure beam (1) includes three main beams (1-1), three middle short beams (1-2) and six Two end short beams (1-3), three main beams (1-1) are horizontally arranged on the same plane in a circular array, and an intermediate short beam is arranged between two adjacent main beams (1-1). Beams (1-2), the three intermediate short beams (1-2) are horizontally arranged on the same plane in a circular array, and the two adjacent main beams (1-1) are far away from the intermediate short beams (1- One side of 2) is respectively provided with an end short beam (1-3), and the two ...

specific Embodiment approach 2

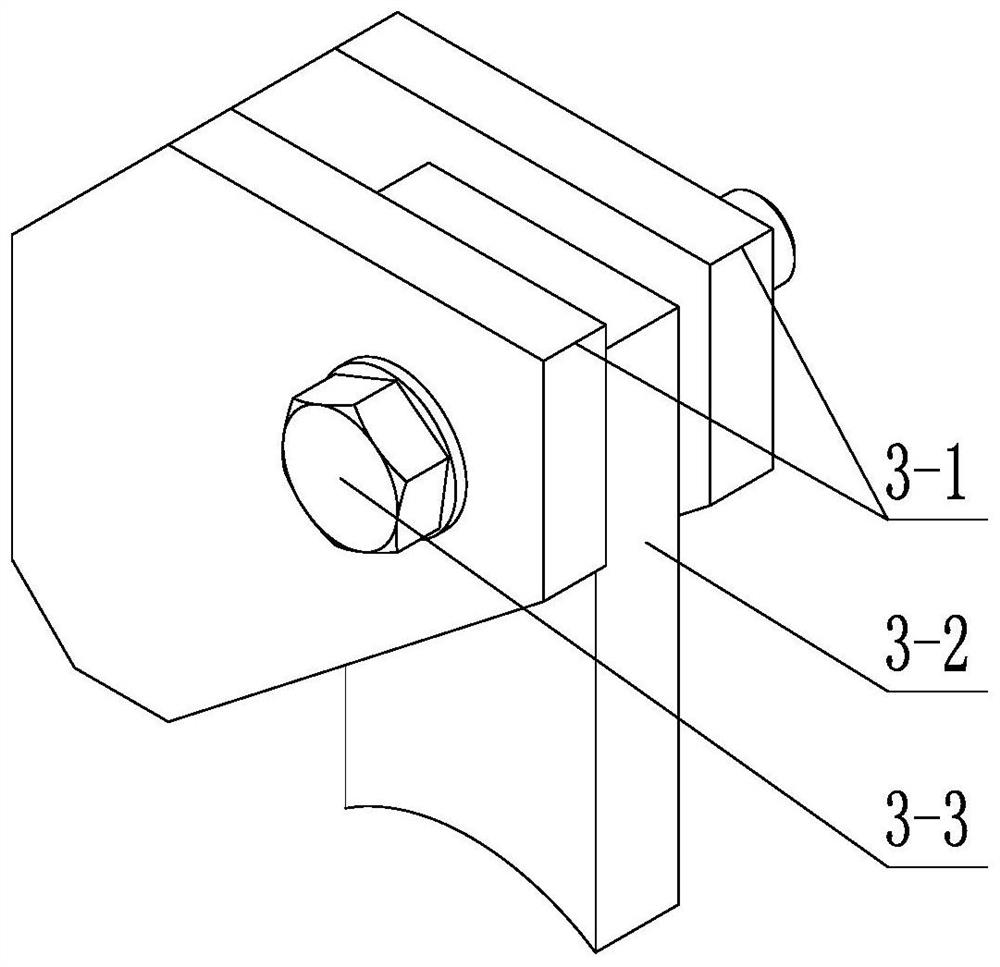

[0028] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, each inner ring header cantilever lug assembly 3 of this embodiment includes a hanging plate 3-2, a connecting element 3-3 and two lugs 3-1, and the two lugs 3-1 are vertically The vertical direction is arranged parallel to the inner end surface of the main beam 1-1 or the inner end surface of the intermediate short beam 1-2, the hanging plate 3-2 is located between the two ear plates 3-1, and the hanging plate 3-2 is connected by The element 3-3 is fixedly connected with the two ear plates 3-1, and the lower end surface of the hanging plate 3-2 is provided with an arc surface matching the outer cylindrical surface of the inner ring header 5. With such arrangement, the reliable bearing of the inner ring header 5 can be realized through the six inner ring header cantilever lug assemblies 3, and the number of the inner ring header cantilever eye assemblies 3 can also be fl...

specific Embodiment approach 3

[0032] Specific implementation mode three: combination figure 1 and figure 2To illustrate this embodiment, the straight lines formed between all the centrally symmetrical two suspension plates 3-2 among the six suspension plates 3-2 of this embodiment converge at one point, and this point coincides with the center of circle of the inner ring header 5. Other compositions and connections are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com