Inner hole protection device and method during long-barrel-shaped part heat treatment carburizing

A technology for protection devices and parts, applied in metal material coating process, coating, solid-state diffusion coating, etc., can solve problems such as difficult operation, uneven copper plating, poor protection effect, etc., to achieve simple operation and guarantee The effect of production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

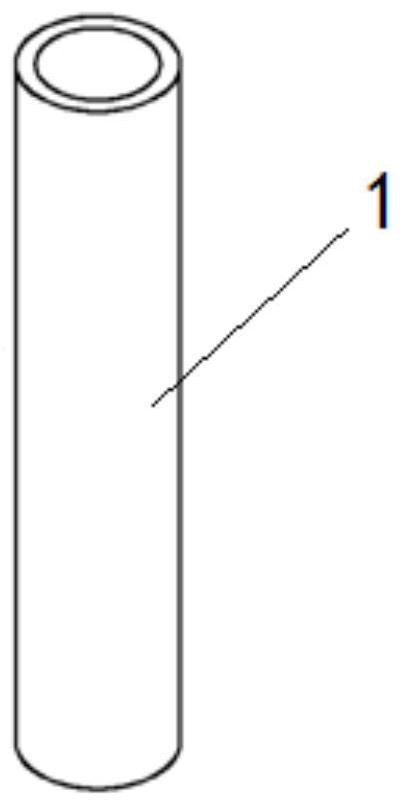

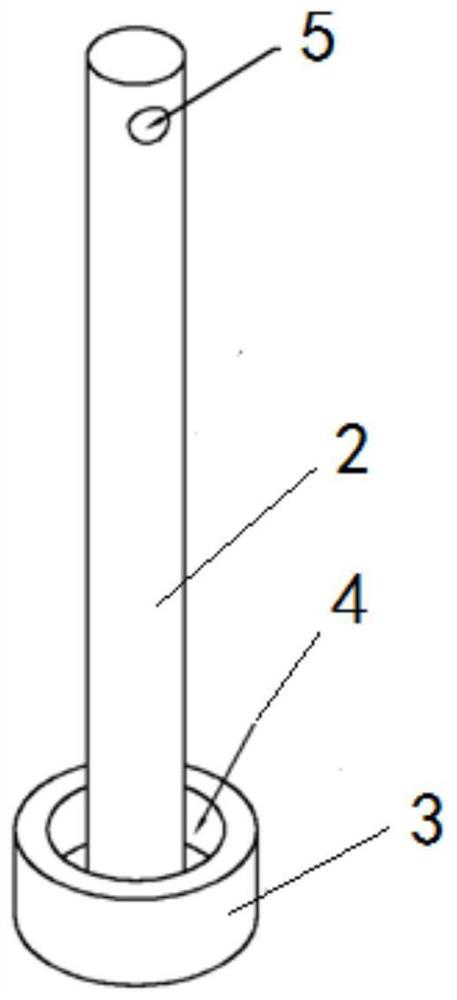

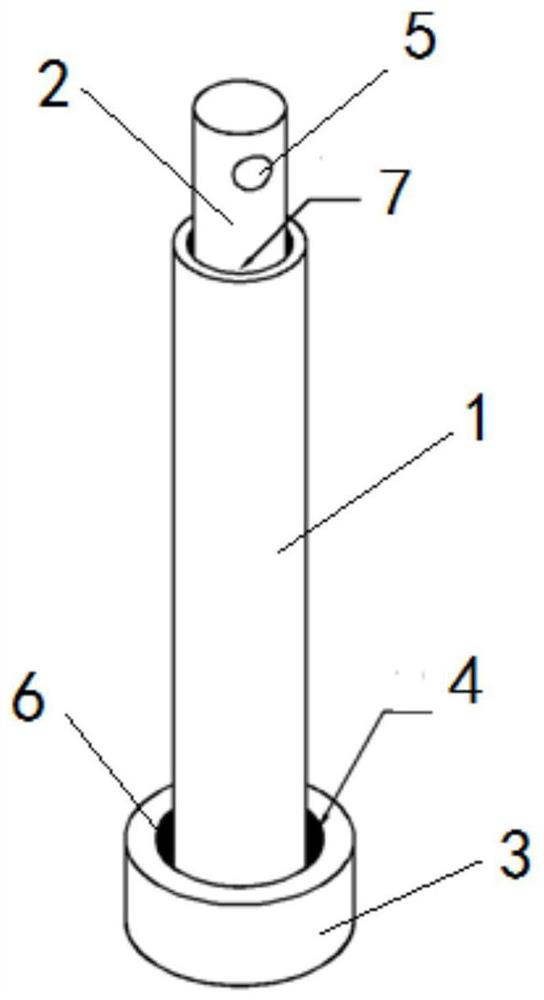

[0013] Referring to the accompanying drawings, the elongated tubular parts involved in the present application are as figure 1 As shown, the part has a deep and thin inner hole, and the heat treatment carburizing inner hole protection of this type of part cannot be realized by using the existing technology. For this reason, the long cylindrical part heat treatment carburizing inner hole protection device proposed by this application is as follows: figure 2 As shown, the device contains a base 3 and a pull rod 2, and the pull rod 2 is fixed on the base 3. The base 3 is a round basin with an open upper end and has a sunken cavity. The lower end of the pull rod 2 is connected to the bottom of the base 3 sunken cavity In the center, an annular groove 4 is formed on the outer side of the lower end of the pull rod 2, the width of the ring groove 4 is greater than the wall thickness of the long cylindrical part 1, the outer diameter of the pull rod 2 is smaller than the inner diamet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com