A concrete pontoon bridge for a floating pier

A technology of concrete and reinforced concrete slabs, which is applied in the direction of pontoon bridges, bridges, bridge forms, etc., can solve the unsatisfactory performance of concrete pontoon bridges in anti-cracking, shrinkage, corrosion resistance, water resistance, anti-wave stability and anti-wave shock performance of concrete bridge boxes. Poor anti-wave stability, poor anti-aging performance and other problems, to achieve the effect of beautiful appearance, improved service life and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

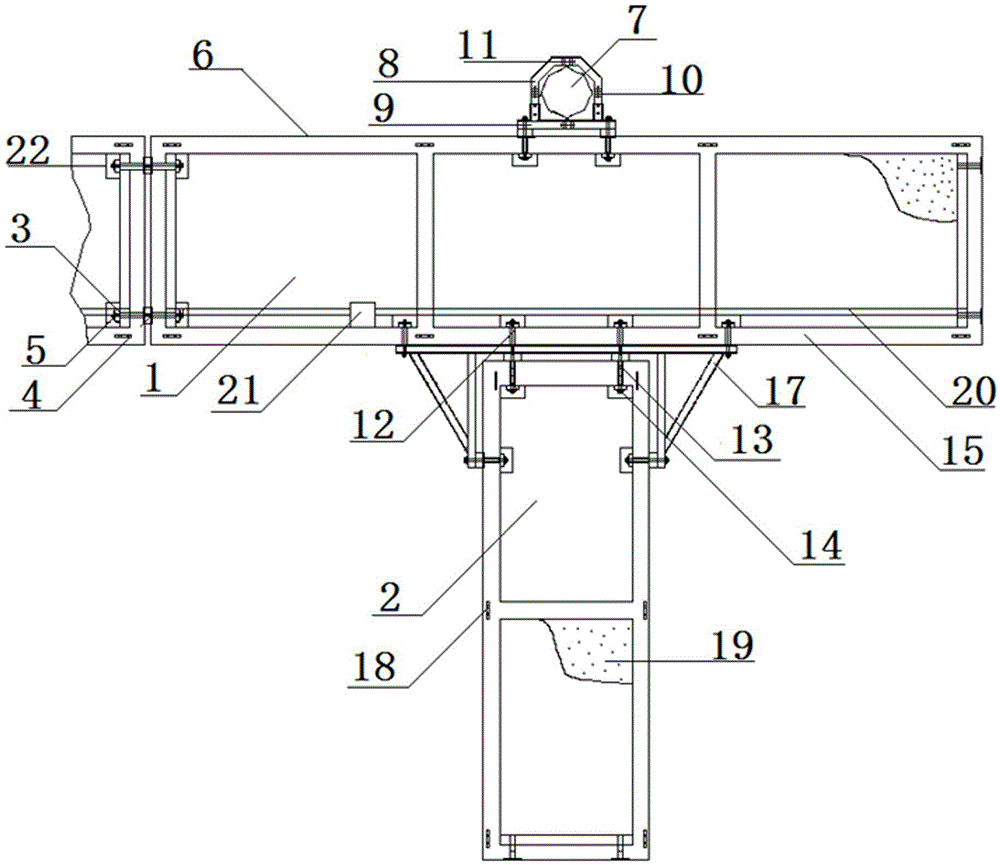

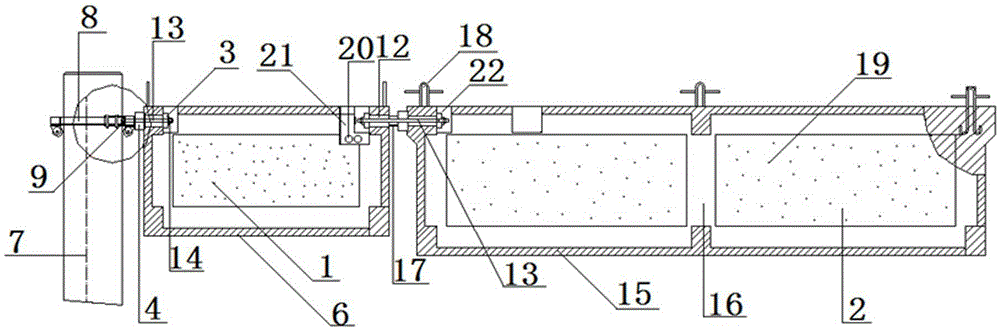

[0030] exist figure 1 , figure 2 , image 3 with Figure 4 Shown in, a kind of concrete pontoon bridge of floating wharf, comprises main bridge bridge box 1, auxiliary bridge bridge box 2, connecting frame 17 and pile-supported bridge frame, auxiliary bridge bridge box 2 and main bridge bridge box 1 are fixed by connecting frame 17 Take on the seabed stake 7. The pile-supported bridge frame includes a pile 7, a pile holder, and a bridge box, and the pile holder is fixed with the pile 7. The pile holder includes a pile holder mother body 9, a pile holder child body 8, a roller 10, and a roller bracket 11. The roller 10 is fixed on the roller bracket 11, and the roller 10 is fixed horizontally on the pile holder. One end of the pile holder is fixed on the pile 7, and the other end is fixed on the bridge box of the floating concrete main bridge. The connecting frame 17 passes through the screw rod 13 , inner buffer pad 3, outer buffer pad 4, stainless steel backing plate 5 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com