A premixing nozzle for a gas turbine combustor

A gas turbine, pre-mixing technology, applied in combustion chambers, continuous combustion chambers, combustion methods, etc., can solve limited problems, achieve the effects of reducing low-speed areas, preventing backfire, and suppressing the existence of local high temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The principle, structure and specific implementation of the present invention will be further described below in conjunction with the accompanying drawings.

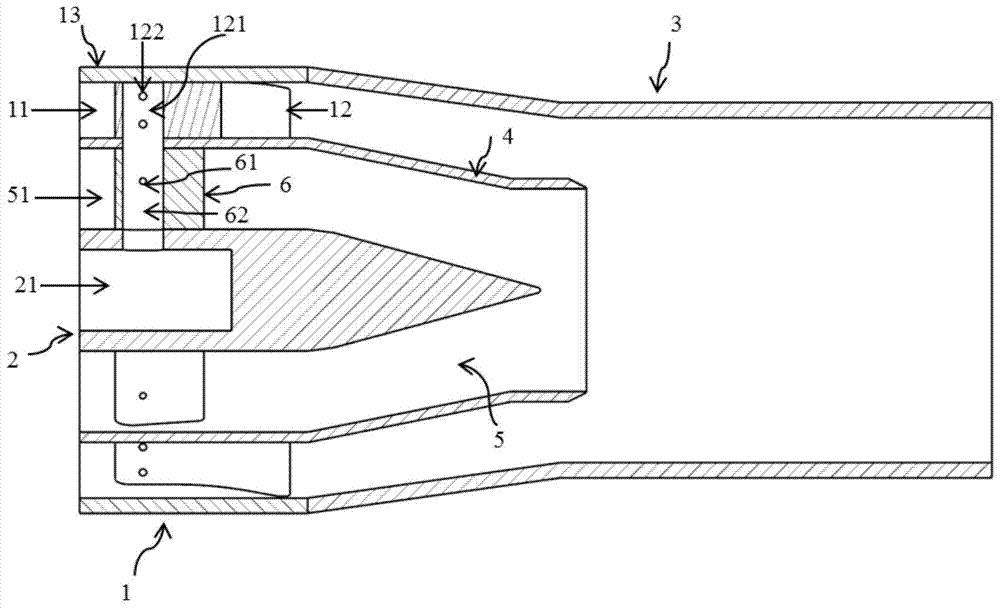

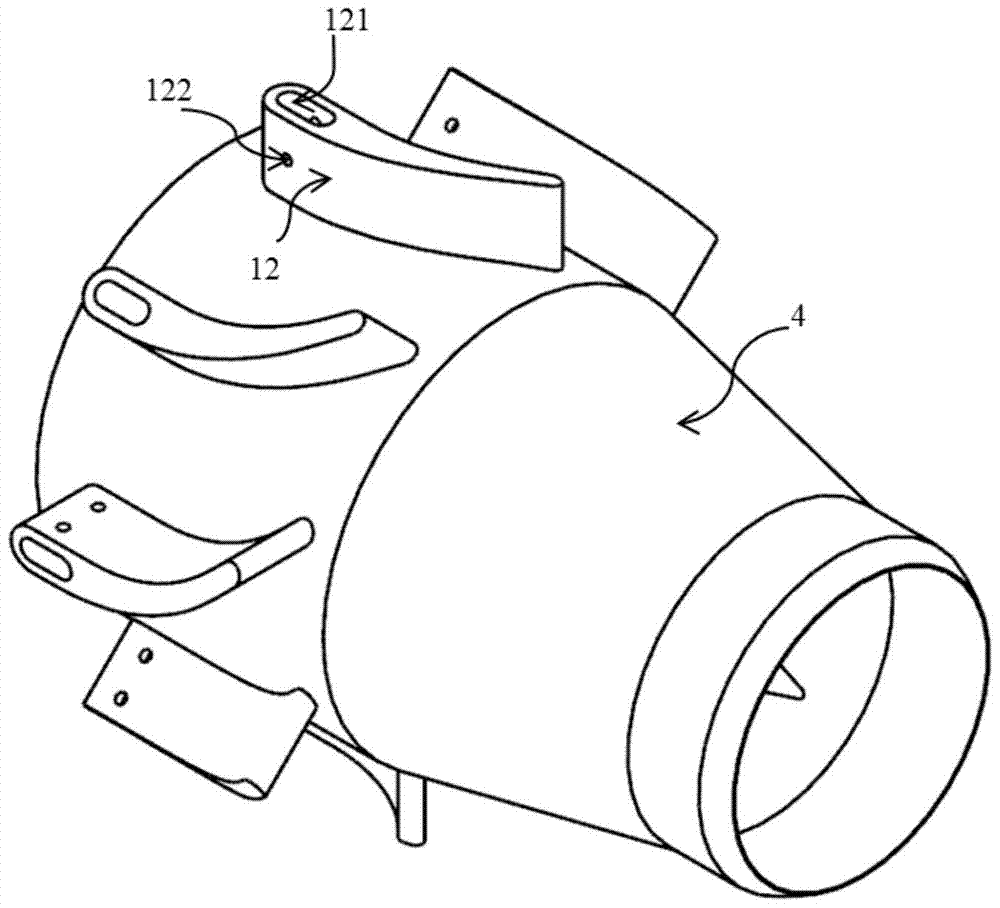

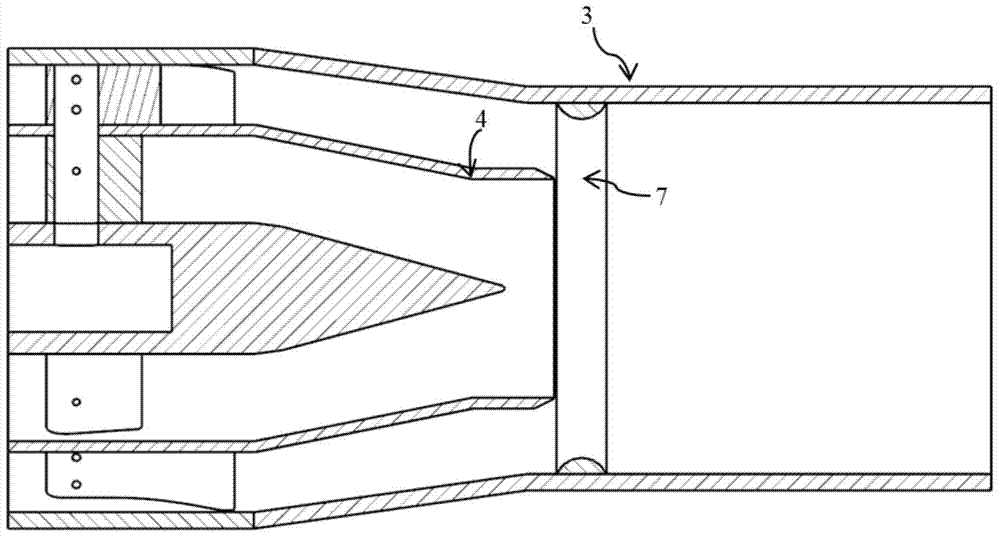

[0018] figure 1 , figure 2 It is a schematic diagram of the structure and principle of a premixing nozzle of a gas turbine combustor provided by the present invention. The nozzle includes an axial swirler 1, a tapered central body 2, and a mixing section 3, wherein the axial swirler 1 is provided with an outer layer air inlet 11, swirl vanes 12 and a swirler outer wall 13, The outer layer fuel outlet 122 and the outer layer fuel passage 121 are arranged on the swirl blade 12, and the central gas fuel inlet 21 is arranged on the tapered central body 2, and on the outside of the tapered central body 2, the axial swirler 1 is provided with a tapered annular tube 4 arranged coaxially with the tapered central body 2, the inner wall of the tapered annular tube and the outer wall of the tapered central body 2 form an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com