Tension-force synchronous controller of coiler for square double-needle power lithium ion battery

A synchronous controller, lithium-ion technology, applied in battery assembly, secondary battery manufacturing, secondary battery and other directions, can solve problems such as increased equipment cost, low real-time performance, and inability to customize, and reduce costs , Improve the effect of winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

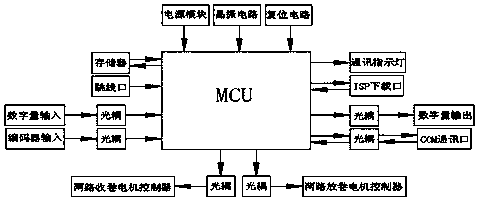

[0022] Such as figure 1 As shown, the tension synchronous controller of the power lithium-ion square double-needle battery winding machine of the present invention includes an MCU arranged in the center, and a memory, jumper port, digital input and encoder input arranged on the left side of the MCU. And the communication indicator light, ISP download port, digital output and COM communication port set on the right side of the MCU, and the power module, crystal oscillator circuit and reset circuit set in front of the MCU in turn, and the two winding motors set behind the MCU Controller and two-way unwinding motor controller; the connection between the digital input, encoder input, digital output, COM communication port, two-way rewinding motor controller and two-way unwinding motor controller and MCU are respectively set There are optocouplers.

[0023] Wherein, the working process of the tension synchronous controller of the battery winding machine is as follows:

[0024] 1)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com