A smoke machine ignition system

An ignition system and fog machine technology, applied in the field of ignition systems, can solve the problems of easy flameout of negative pressure fuel, cumbersome ignition operation, and low ignition success rate, and achieve high ignition success rate, good atomization effect, and accurate coordination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

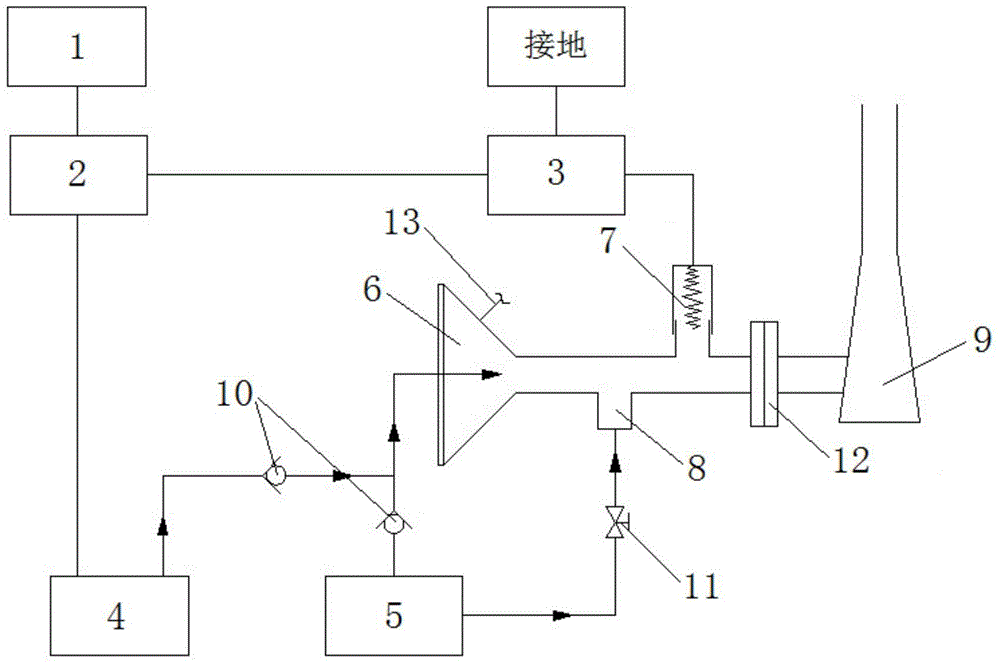

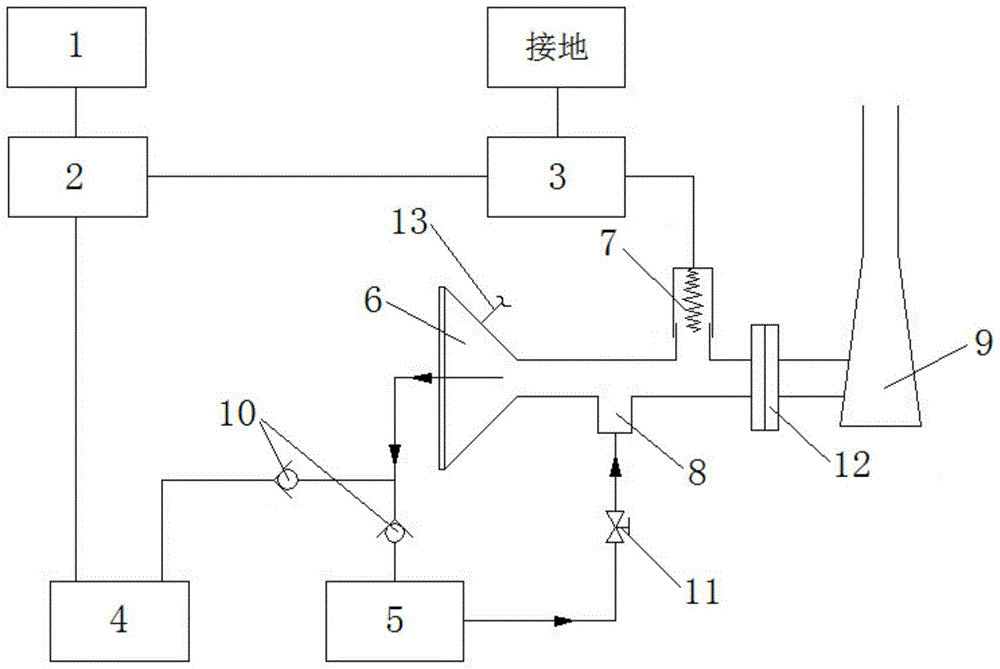

[0027] combine figure 1 and figure 2 , a kind of fog machine ignition system of the present embodiment, comprises power supply 1, ignition switch 2, igniter 3, air pump 4, fuel tank 5, carburetor 6, spark plug 7, fuel injection nozzle 8 and combustion chamber 9, igniter 3 and the air pump 4 are electrically connected to the power supply 1 through the ignition switch 2, and the ignition switch 2 controls the start and stop of the igniter 3 and the air pump 4 at the same time, which reduces the trouble of step-by-step operation, and is beneficial to the mutual cooperation of the ignition of the spark plug 7 and the mixing of fuel. Improve the ignition success rate; the igniter 3 is electrically connected to the spark plug 7, and the igniter 3 needs to be grounded at the same time to ensure that the smoke machine can be ignited normally; the air pump 4 is respectively connected to the fuel tank 5 and the carburetor 6 through the gas pipeline. It consists of two branches separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com