Piston-type minisize filter pump

A technology of piston type and filter pump, which is applied in the direction of fixed filter element filter, filter separation, semi-permeable membrane separation, etc. It can solve the problems of inconvenient use, large volume, unsuitable for sterile filtration, etc., and achieves convenient transportation and placement, The effect of small size and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] 1. Filtration is completed during the one-way transfer of piston pump liquid to reduce the volume of the device and facilitate direct packaging.

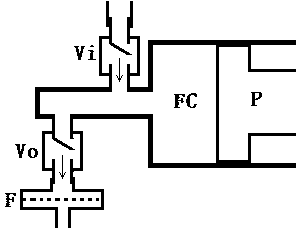

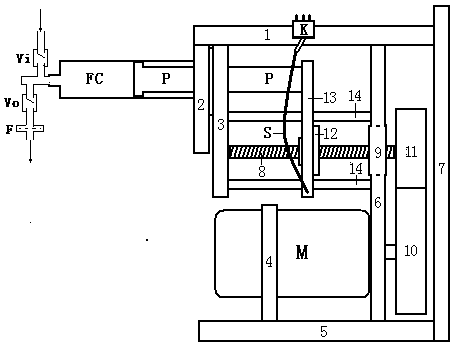

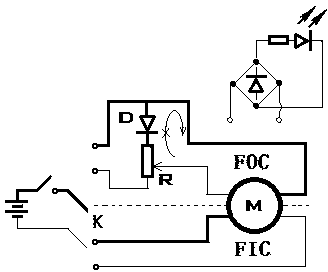

[0015] In order to reduce the volume, the device designed by the present invention does not fully load the liquid to be filtered when it is working, but constructs an open-circuit one-way transfer process that is carried out in a cycle: the guide tube, the filter F, the one-way valves Vi and Vo , small liquid container such as figure 1 Connect, the Vi conduction flow direction points to the inside of the liquid containing cylinder, and the Vo conduction flow direction points to the outside of the liquid containing cylinder. Therefore, the use of two one-way valves enables the inflow (also known as sample injection, liquid suction) and discharge of liquid to be completed in two pipelines. When the piston P moves upwards, under the action of high pressure in the FC, the liquid is discharged out of the FC through Vo, F and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com