Hydrodynamic performance measuring mechanism in stability testing device for ship model in waves

A technology of test device and measuring mechanism, which is applied in ship construction, ship parts, transportation and packaging, and can solve problems such as side corridor pitch displacement and heave displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

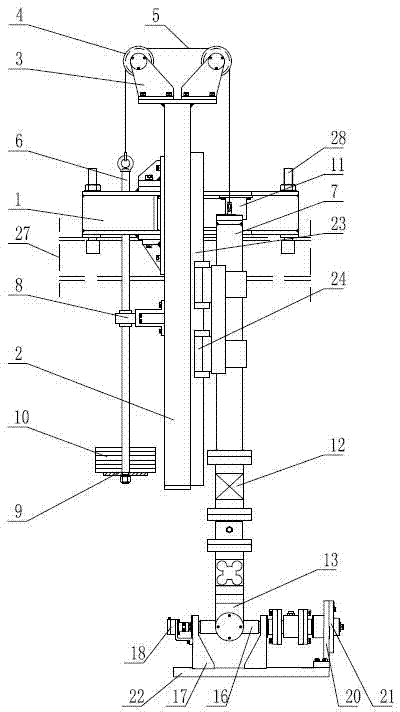

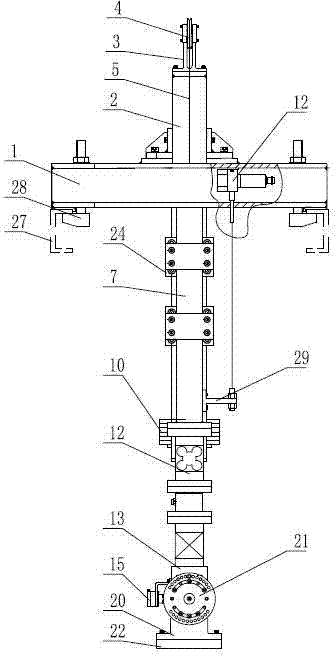

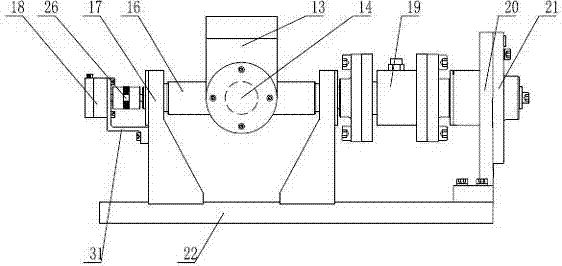

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] See figure 1 , figure 2 , the present invention includes a base 1 straddling and slidably supported on the trailer bridge 27, specifically, the base 1 can be slidably connected to the trailer bridge 27 through a pair of linear guide rails, and the base 1 is provided with a locking The claw 28 is used for locking the base 1 and the trailer measuring bridge 27; the support frame 2 passes through the base 1 and is fixedly connected with the base 1, and the upper end of the base 1 is fixedly provided with a pair of mounting seats-3, and the mounting seat-3 The pulley 4 is installed through the bearing device, and the steel wire rope 5 is wound horizontally on the pulley 4. One end of the steel wire rope 5 is connected with the weight bar 6 through the hook and earring assembly, and the other end of the steel wire rope 5 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com