Progressive feeding type feed device of cotton long fiber raw materials

A feeding device and long-fiber technology, applied in the direction of transportation and packaging, conveying bulk materials, conveyors, etc., can solve the problems of reduced service life of pulping equipment, failure of material winding screw, uneven feeding, etc., to ensure continuous Effects of normal production, elimination of winding, improvement of feeding efficiency and feeding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

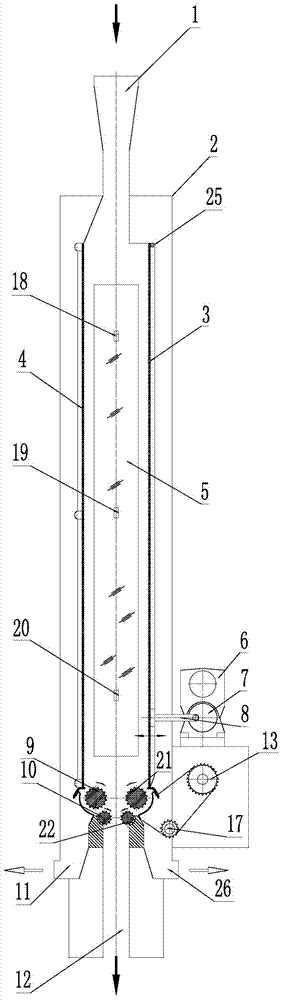

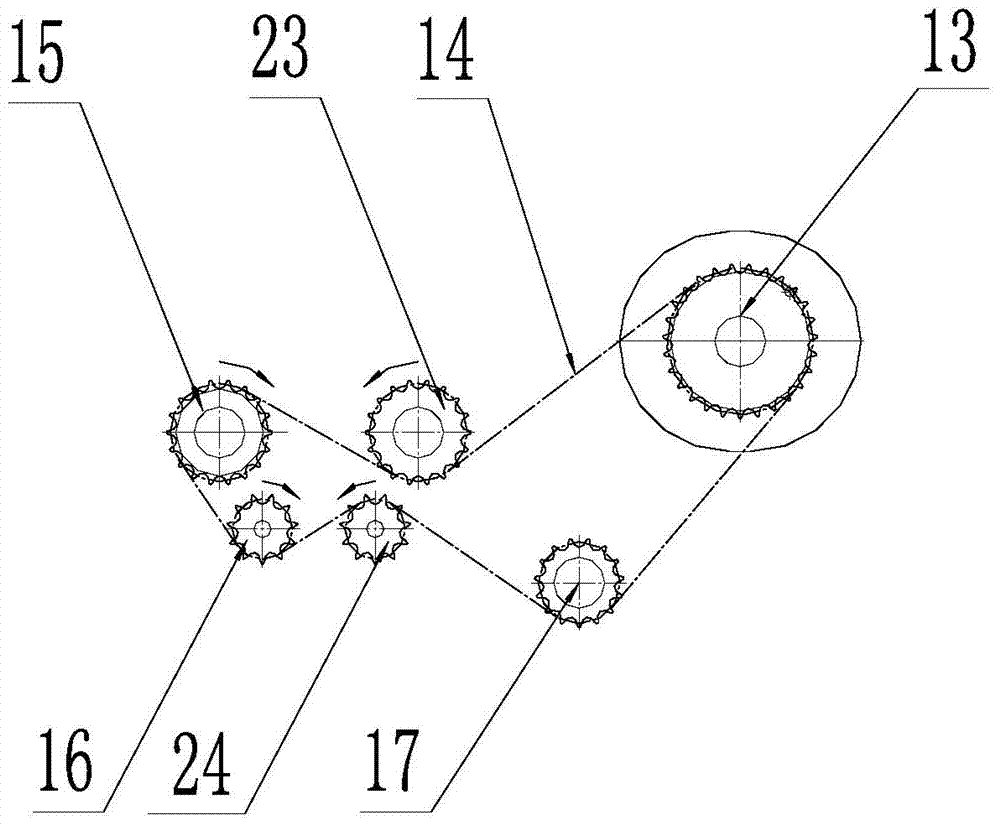

[0026] Example 1: Structural diagram such as figure 1 As shown, the feeding device includes a feed port 1, a housing 2 and a discharge port 12, the feed port 1 is located at the top of the housing 2, and the discharge port 12 is located at the bottom of the housing 2, and the housing 2 is provided with a feeding cavity; the housing 2 includes a first position plate and a third position plate opposite to each other, a second position plate and a fourth position plate opposite to each other, and a top plate and a bottom plate. The first position plate, the second position plate, the third position plate, and the fourth position plate are surrounded in sequence, and the upper connecting top plate and the lower connecting bottom plate together form a feeding cavity; The bucket, of course, can also be directly arranged on the top plate and is positioned at the top of the housing 2 .

[0027] Among them, the first position plate and the third position plate are symmetrically prov...

Embodiment 2

[0038] Example 2: The structure is basically the same as that of Embodiment 1, and the similarities are no longer repeated, but the difference is:

[0039] The first position plate and the third position plate are also provided with 2 pairs of material level sensors, and the transmitter and receiver of each pair of material level sensors are correspondingly arranged on the first mirror and the third mirror; The two pairs of material level sensors are respectively an upper limit material level sensor and a lower limit material level sensor from top to bottom.

[0040] The vibrating orifice plate and the fixed orifice plate are uniformly provided with several cylindrical plate holes.

[0041] The vibrating orifice vibrating device includes an upper pull rod, a lower rod and a pumping drive device. One end of the upper pull rod and the lower rod passes through the fourth position plate to connect to the vibrating orifice plate, and the other end is connected to the pumping driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com