Novel aluminum-composite-wood energy-saving door window system

An aluminum-wood composite, door and window technology, applied in the field of doors and windows, can solve the problems of poor water tightness, high technical requirements, poor sealing performance of doors and windows, achieve good sealing performance and thermal insulation performance, reduce technical requirements, and improve the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

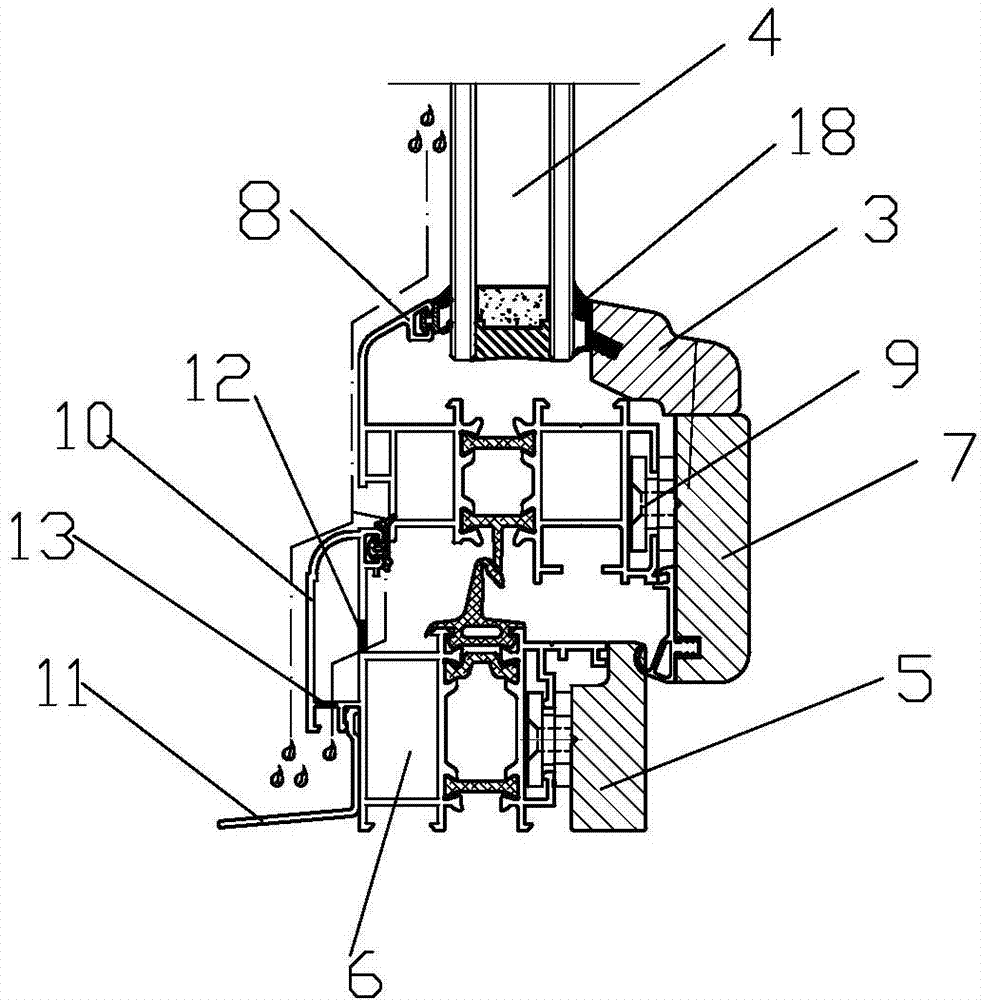

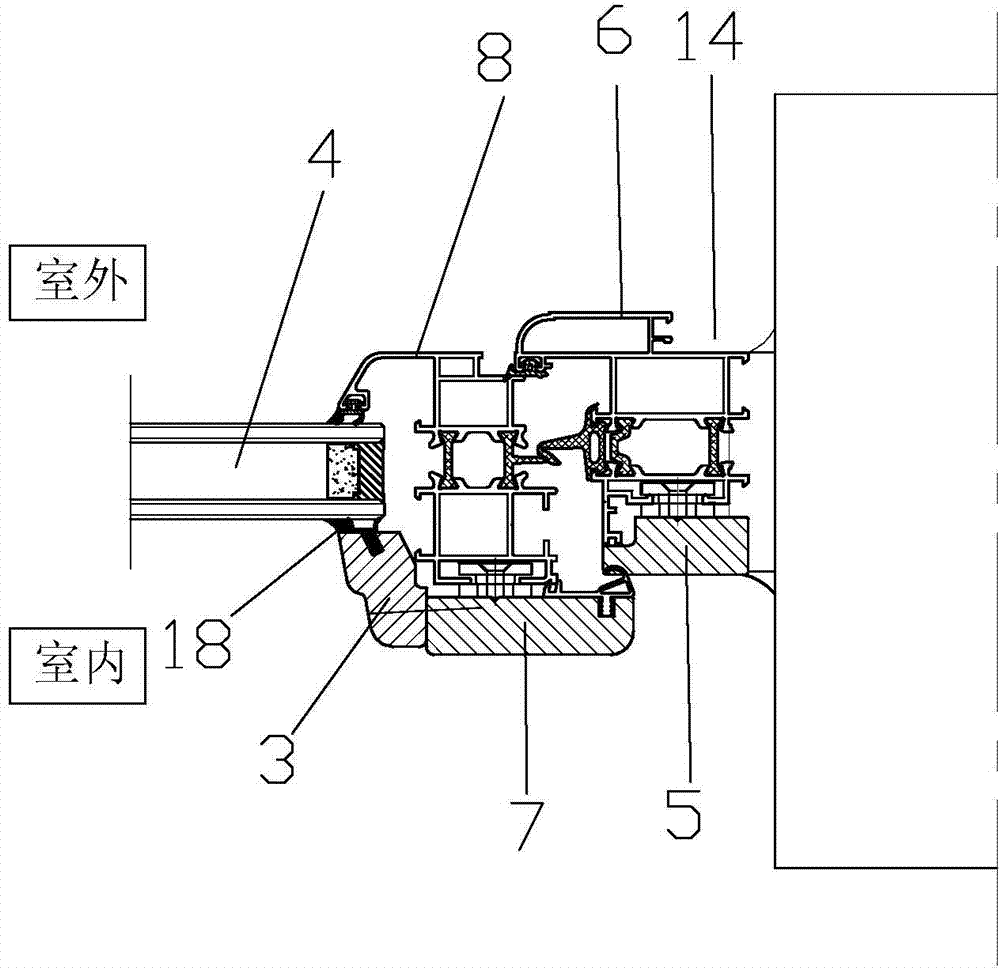

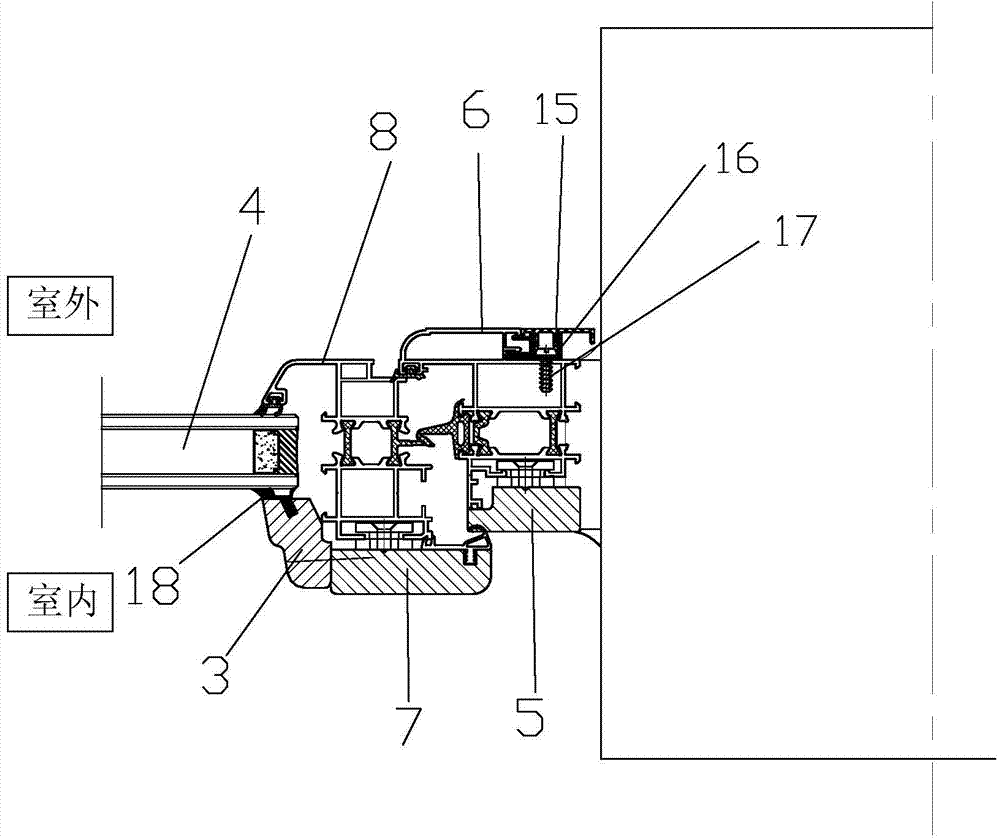

[0018] Embodiment: A new aluminum-wood composite energy-saving door and window system, including:

[0019] Window frames, fan frames, wooden crimping lines 3 and insulating glass 4 that are set in coordination with each other, such as figure 1 As shown, the window frame includes a wooden window frame 5 arranged on the indoor side and an aluminum window frame 6 arranged on the outdoor side, and the fan frame includes a wooden fan frame 7 arranged on the indoor side and an aluminum fan frame 8 arranged on the outdoor side, so The hollow glass 4 is embedded between the aluminum fan frame 6 and the wooden pressure wire 3, and the sealant 18 is applied at the external contact between the hollow glass 4, the aluminum fan frame 8 and the wooden pressure wire 3, so as to improve the sealing performance and Firmness; the wooden window frame 5 and the aluminum window frame 6, the wooden fan frame 7 and the aluminum fan frame 8 are all connected and fixed by the aluminum-wood connector 9...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap