Kriging model based wind turbine gearbox fault diagnosis method

A fault diagnosis and gearbox technology, which is applied in machine gear/transmission mechanism testing, sustainable building, climate sustainability, etc., can solve problems such as poor real-time performance, large amount of calculation, and difficulty in meeting actual engineering needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

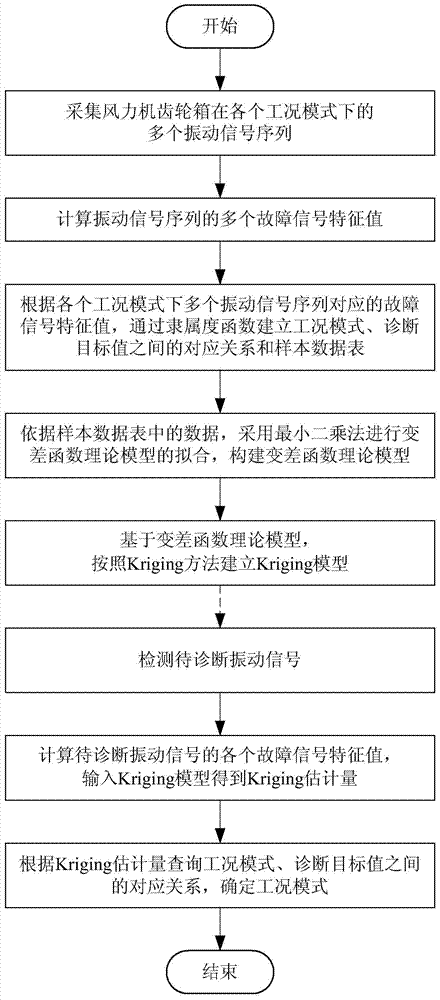

[0059] Such as figure 1 As shown, the implementation steps of the wind turbine gearbox fault diagnosis method based on the Kriging model in this embodiment are as follows:

[0060] 1) Separately collect multiple vibration signal sequences of the wind turbine gearbox in each working mode, each working mode includes the normal state, wear state and broken tooth state of the wind turbine gearbox; The vibration signal sensor at the proper position detection point of the wind turbine gearbox is used to collect the vibration signal of the gearbox, and the fault signal of the gearbox is collected by the vibration acceleration sensor. The sampling frequency is 8192Hz and the effective sampling time is ≥ 2s.

[0061] 2) Calculate a plurality of fault signal eigenvalues of the vibration signal sequence respectively;

[0062] 3) According to the fault signal eigenvalues corresponding to multiple vibration signal sequences in each working mode, the corresponding relationship between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com