Composite-type powerful deep-loosening soil pulverizer

A combined and crusher technology, applied in clod crushers, tillage equipment, agricultural machinery and equipment, etc., can solve the problems of long front and rear span, high fuel consumption, large resistance and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

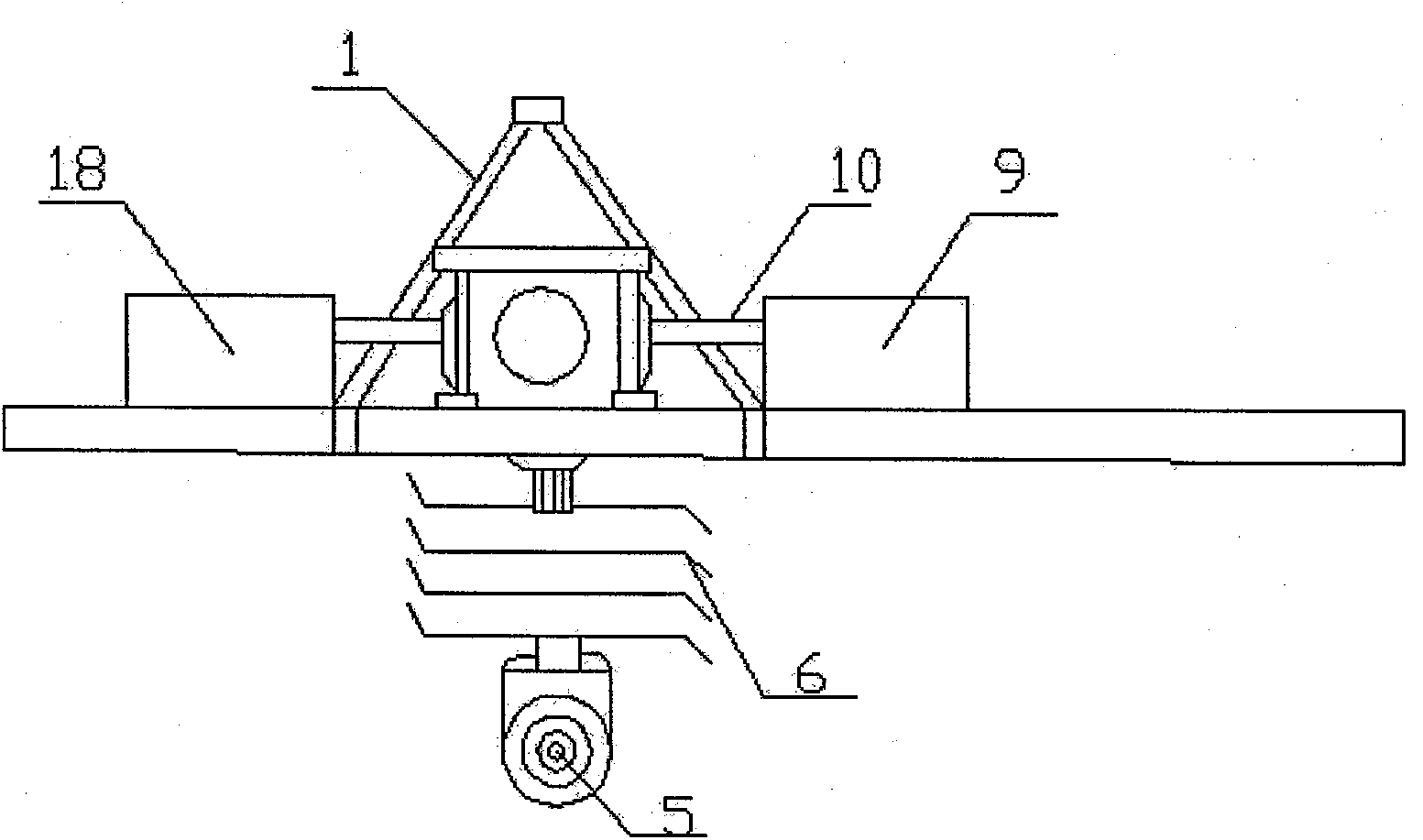

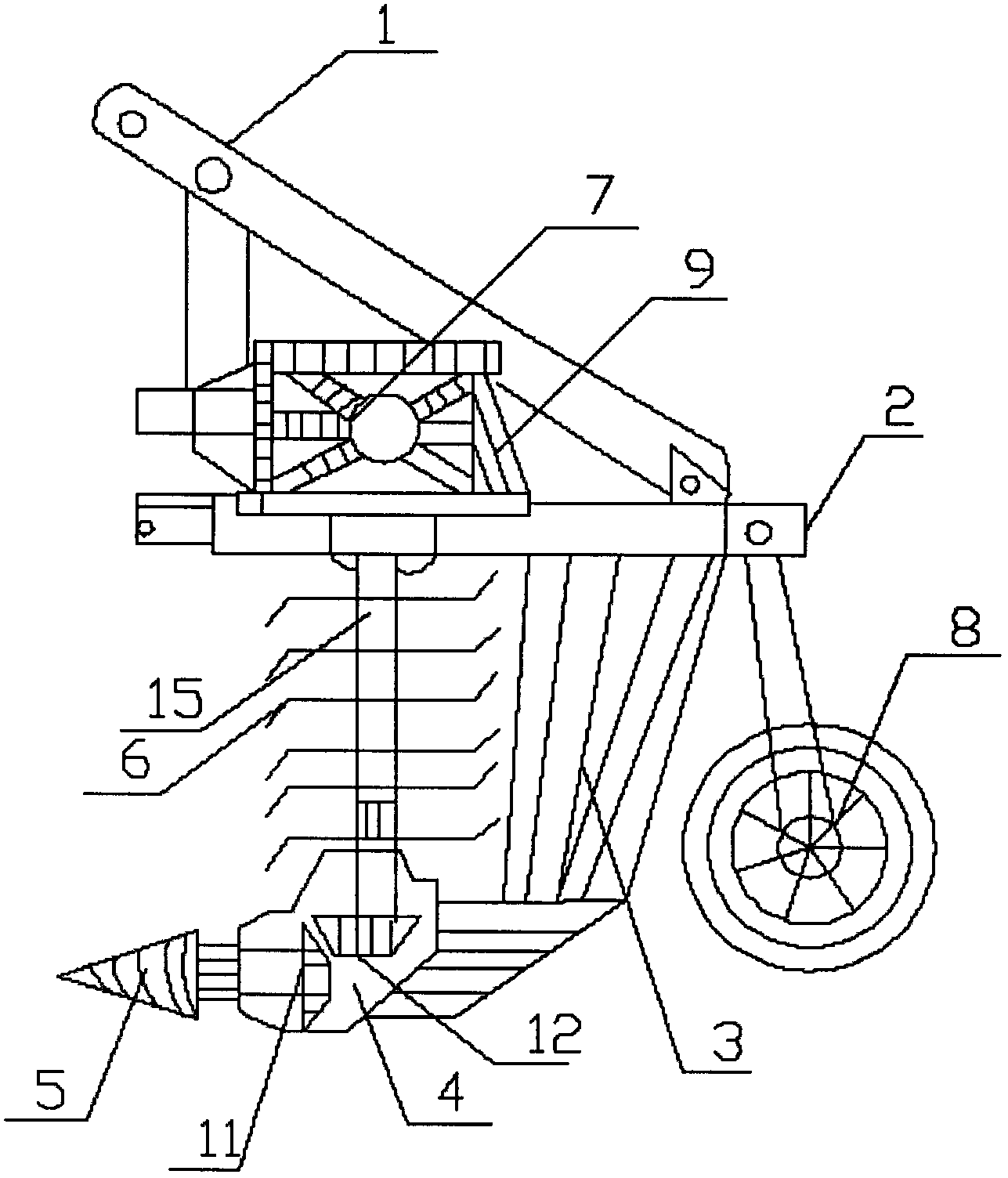

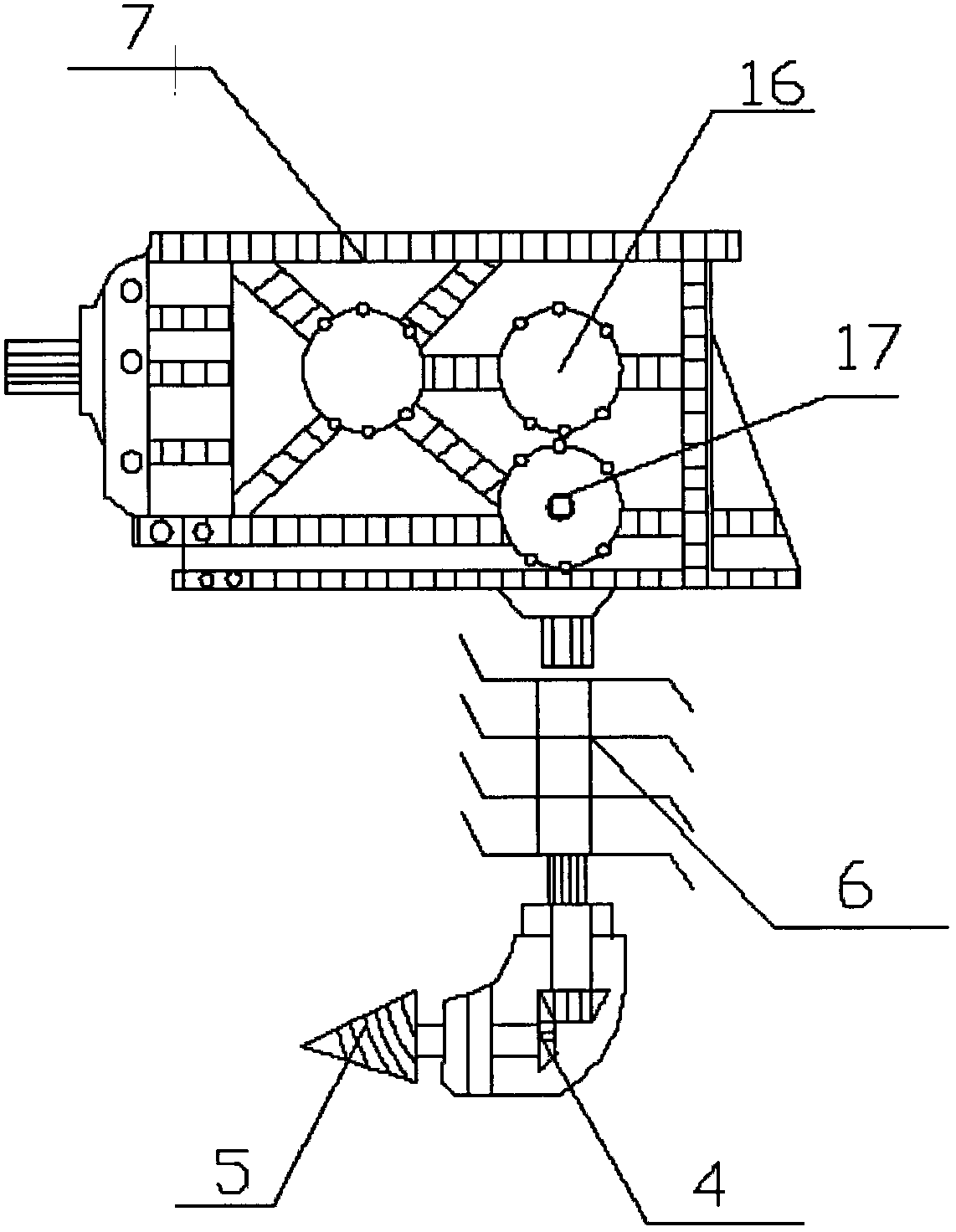

[0021] Such as figure 1 and figure 2 As shown, a combined powerful subsoil breaker of the present invention includes a frame assembly 2, a tripod 1 arranged on the upper end of the frame assembly 2, and an active box 7 arranged between the tripods 1, so One side of the active box 7 is connected with a side transmission shaft 10, the other end of the side transmission shaft 10 is connected with a first side auxiliary transmission box 9 and a second side auxiliary transmission box 18, and the lower end of the active box 7 is connected with a transmission knife shaft 15, the upper end of the transmission knife shaft 15 is equipped with a horizontal soil breaking knife 6, the lower end of the transmission knife shaft 15 is connected with a spiral box 4, and the outer end of the spiral box 4 is connected with an auger bit 5 arranged parallel to the horizontal plane. The auger bit 5 is arranged in the helical box 4, and one end is connected with the first helical gear 11, the end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com