Positioning tool for welding rib plates on cylindrical member

A technology for positioning tooling and cylindrical shapes, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of increasing the difficulty of welding ribs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

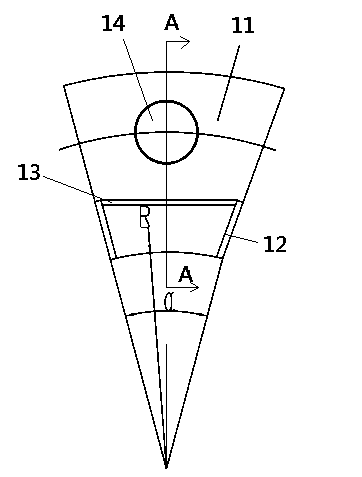

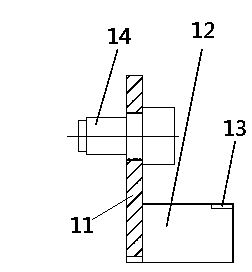

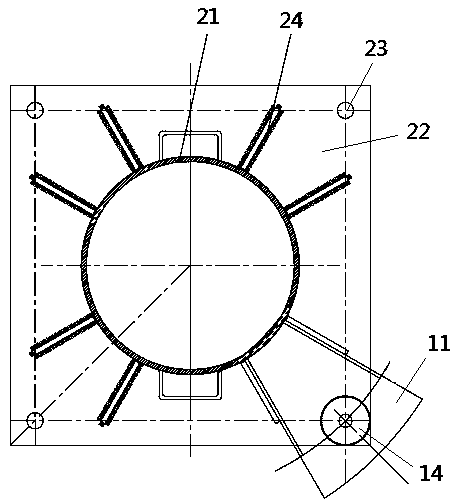

[0017] Embodiments of positioning fixtures for welding ribs to cylindrical objects, such as Figure 1-3 As shown, the tooling includes an indexing base block 11. In this embodiment, the indexing base block 11 is in the shape of a truncated sector, and the section formed after the lower part is truncated is an arc surface. Assume that the radius of the arc surface is R , then when the indexing base block is placed on the cylindrical object to be welded with an outer diameter of R, it can prevent the indexing base block 11 from swinging left and right on the cylindrical object to be welded, that is, the remaining circle at the truncated part The arc surface forms the anti-swing structure of the indexing base block 11; in addition, the left and right sides of the indexing base block 11 form positioning slopes respectively, and the two positioning slopes gradually move away from each other from bottom to top. In order to position and fit the corresponding ribs to be welded, in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com