Reversed filtration block prepared from coal slag or mineral slag and preparation method thereof

A technology for coal slag and slag, which is applied in the field of reverse filter block and its preparation, can solve the problems of difficult control of construction quality, slow construction affecting progress, deformation and damage of inclusions, etc. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

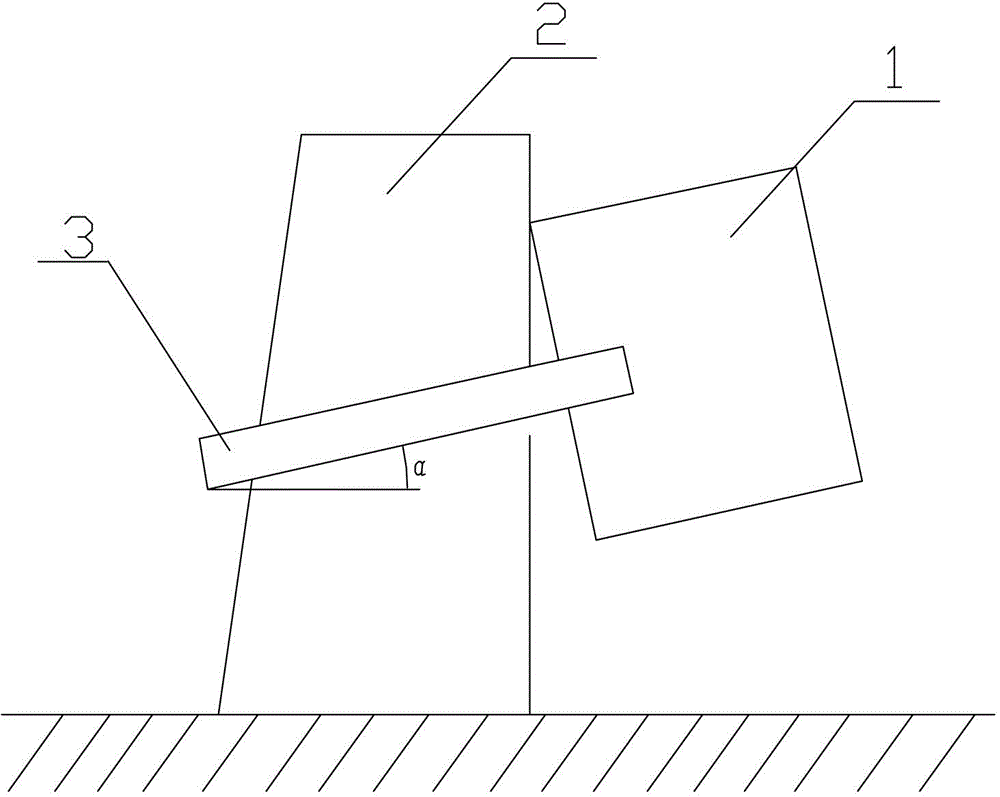

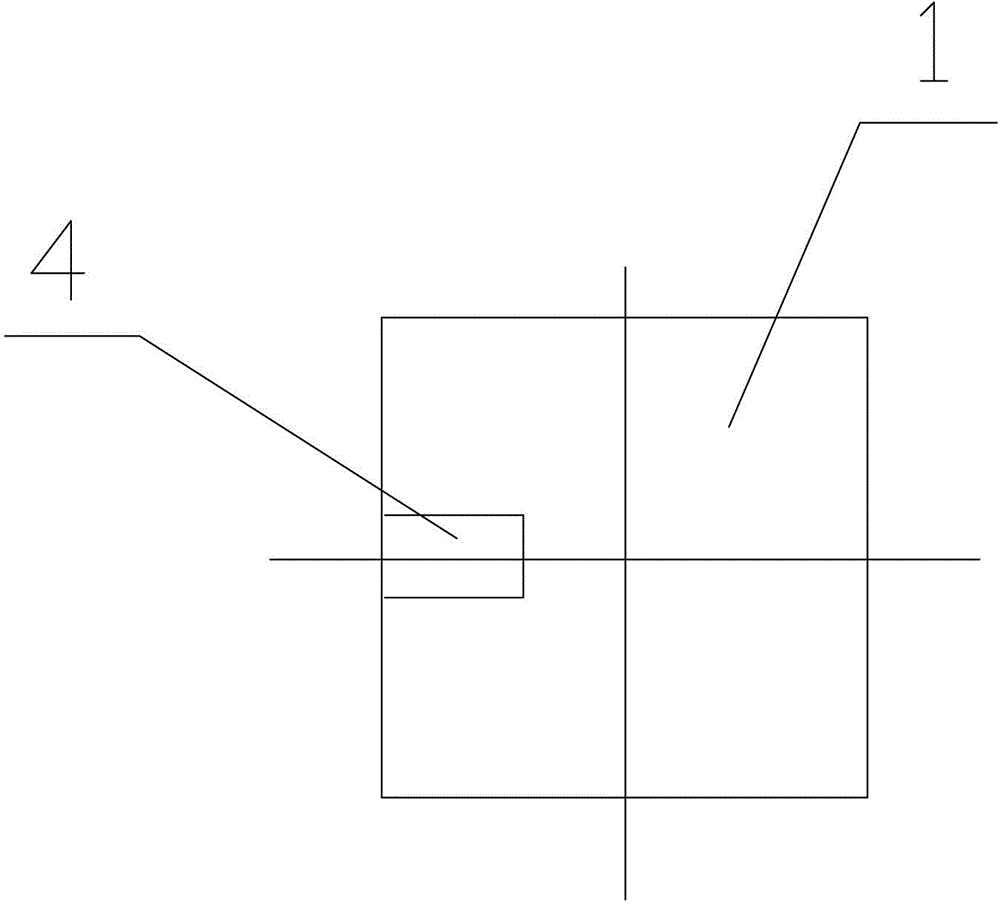

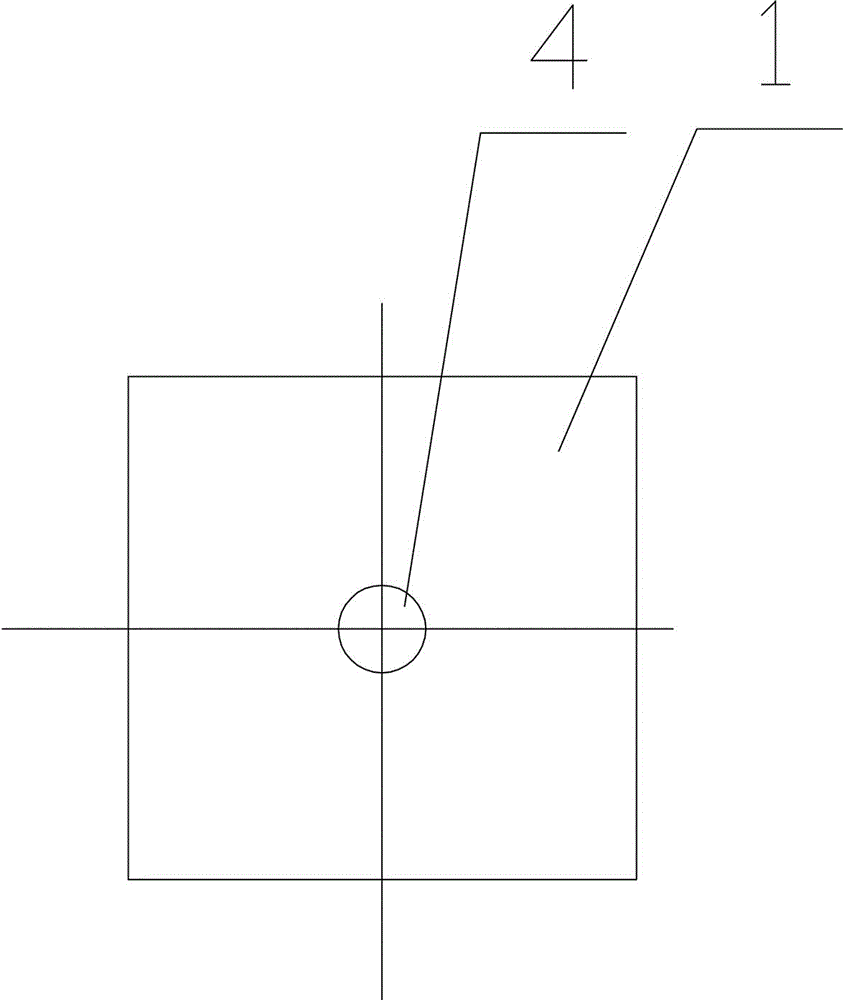

Method used

Image

Examples

Embodiment 1

[0036] Ingredients of the present invention: get 100 parts of cement and 700 parts of coal slag in parts by weight, wherein the coal slag is broken into 10-100mm slag blocks, and the content of <10mm slag blocks is less than 15%; the compressive strength of the obtained reverse filter block Reach above 0.4Mpa, its production method is the same as above.

Embodiment 2

[0038] Ingredients of the present invention: take 100 parts of cement and 720 parts of slag by weight, wherein the slag is broken into 10-100mm slag blocks, and the content of <10mm slag blocks is less than 15%; the compressive strength of the prepared reverse filter block reaches 0.35 Above Mpa, its production method is the same as above.

Embodiment 3

[0040] Ingredients of the present invention: get 100 parts of cement and 740 parts of coal slag in parts by weight, wherein the coal slag is broken into 10-100mm slag blocks, and the content of <10mm slag blocks is less than 15%; the compressive strength of the prepared reverse filter block Reach above 0.3Mpa, its production method is the same as above.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com