Compounding side stream for polyamide synthesis

A technology of main polyamide flow, polyamide, applied in the field of side flow of polyamide synthesis, which can solve the problems of insufficient mixing, fouling of by-product forming equipment, introduction of pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

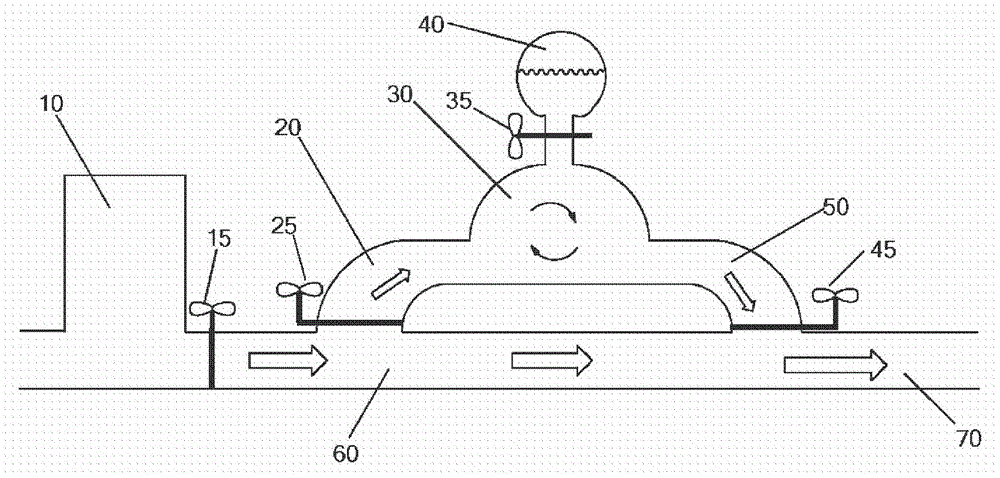

Image

Examples

preparation example Construction

[0083] The preparation of fiber-forming polyamides from diamine-dicarboxylates can be carried out in several ways. The salt can be heated to the reaction temperature (180°C-300°C) in the absence of solvent or diluent under conditions that allow the removal of water formed in the reaction.

[0084] Polyamide polymerization reactions may be subjected to reduced pressure, eg, equal to 50 to 300 mm Hg (67 to 400 mbar) absolute, to facilitate substantially complete polymerization. For example, the reaction vessel in which the polyamide is prepared can be evacuated, after which the polymer is allowed to cure.

[0085] In general, no catalyst needs to be added in the polyamide formation process described above. However, certain phosphorous-containing materials can perform a certain degree of catalytic function. Phosphorus-containing materials may include metal phosphonates. The use of additional catalysts can facilitate the production of high molecular weight materials.

[0086] ...

Embodiment 1a

[0100] Example 1a: Addition of Additives to Partially Polymerized Nylon

[0101]A 10% aqueous suspension of titanium dioxide anatase additive preheated to 130° C. was pumped to the partially formed polyamide solution leaving the evaporator with a time interval of not more than 30 seconds from heating to injection. The polyamide stream leaving the evaporator had a flow rate of about 75 L / min and the 10% additive stream (steam) had a flow rate of about 1.7 L / min. These combined streams flow into the reactor. The polymer leaving the finisher at 59 L / min had an intrinsic viscosity of 0.9 and contained 0.3% by weight additive.

[0102] The system was shut down after 12 weeks of operation. Significant additive deposition was observed in the flasher and other downstream components. The titania reagent coats the heat transfer surface with an average thickness of about 0.2 mm, reducing the efficiency of heat transfer in this process.

Embodiment 1b

[0103] Example 1b: Addition of additives to partially polymerized nylon in the extruder

[0104] A side stream additive unit is placed downstream of the flasher. The inlet valve was opened to divert about 5% by weight of substantially polymerized nylon from the main flow of nylon into the mixing chamber of the side stream additive unit. The mixing chamber was uniformly heated to a temperature equal to that of the substantially polymerized nylon in the main flow (about 280°C). The mixing chamber mixes the titanium dioxide anatase additive with the split stream of substantially polymerized nylon to form a uniform additive stream having a water content of about 0.1-0.2% by weight and a temperature of about 280°C. The polymer mixture flowed through the mixing chamber at about 3 L / min, had an average total residence time in the mixing chamber of about 10 minutes, and achieved a titanium dioxide concentration of about 6% by weight. A uniform nylon-additive flow was passed through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com