Nylon salt solution preparation processes with trim diamine

A nylon salt and solution technology, applied in the field of nylon salt solution preparation, can solve the problems of increasing the amount of equipment, investment cost and energy cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

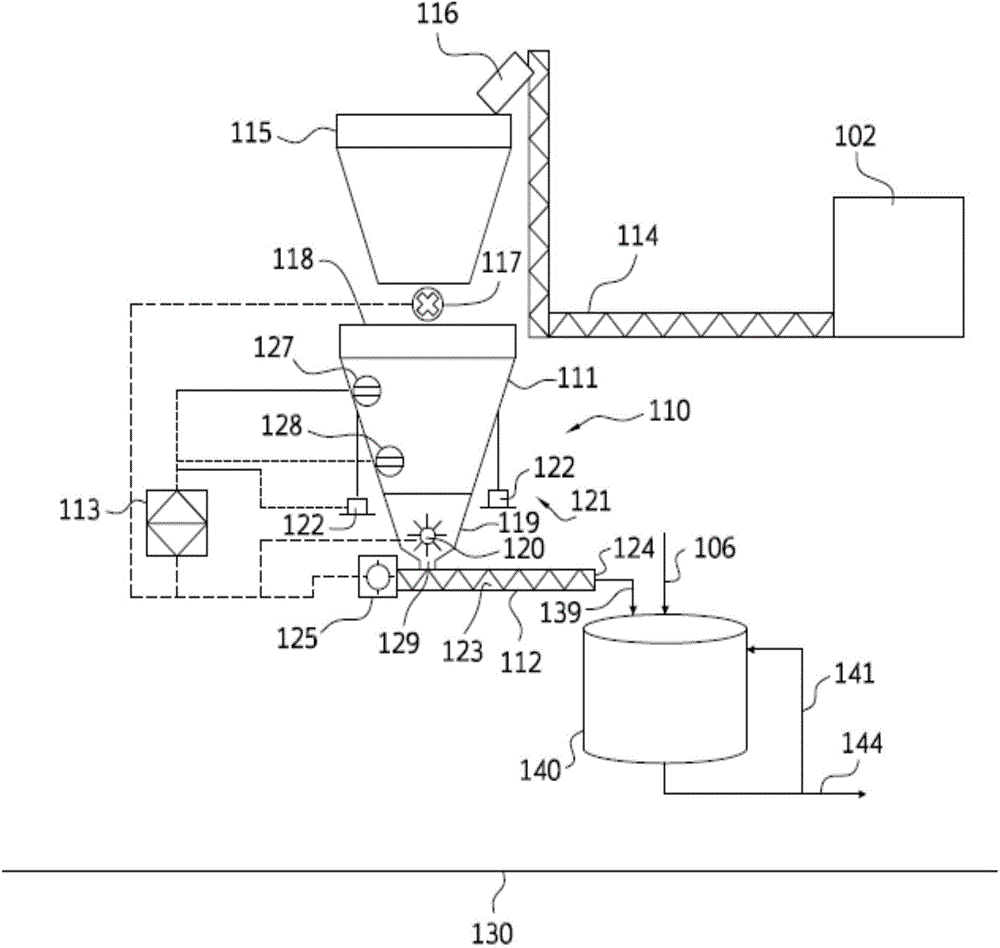

[0139]Using a mechanical conveying system (i.e. screw / haul chain) or pneumatic conveying system (i.e. pressurized air, vacuum air or closed loop nitrogen) via FIBC discharge, lined FIBC discharge, lined box container discharge or hopper The rail car unloading station moves the AA powder from the unloading system to the supply container.

[0140] The supply container moves the desired AA powder into a loss-in-weight (L-I-W) feeder, which uses a PLC to adjust based on the low and high positions of the L-I-W hopper selected. The supply vessel meters the AA powder via a screw conveyor or rotary feeder at a sufficient loading rate such that at a maximum interval equal to, and preferably less than, two times the minimum L-I-W discharge time from the high to low L-I-W bin One-half fills the L-I-W feeder hopper so that a feedback signal of the L-I-W feeder feed rate is received at least 67% of the time.

[0141] The L-I-W feed system adjusts the rate of the L-I-W feed screw, as detec...

Embodiment 2

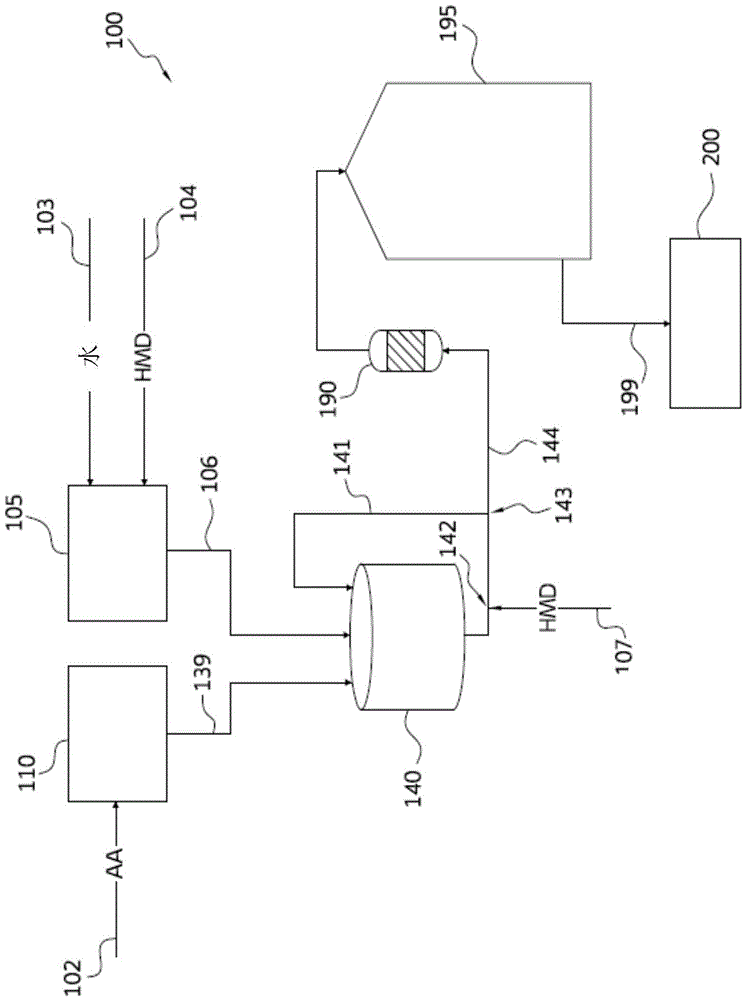

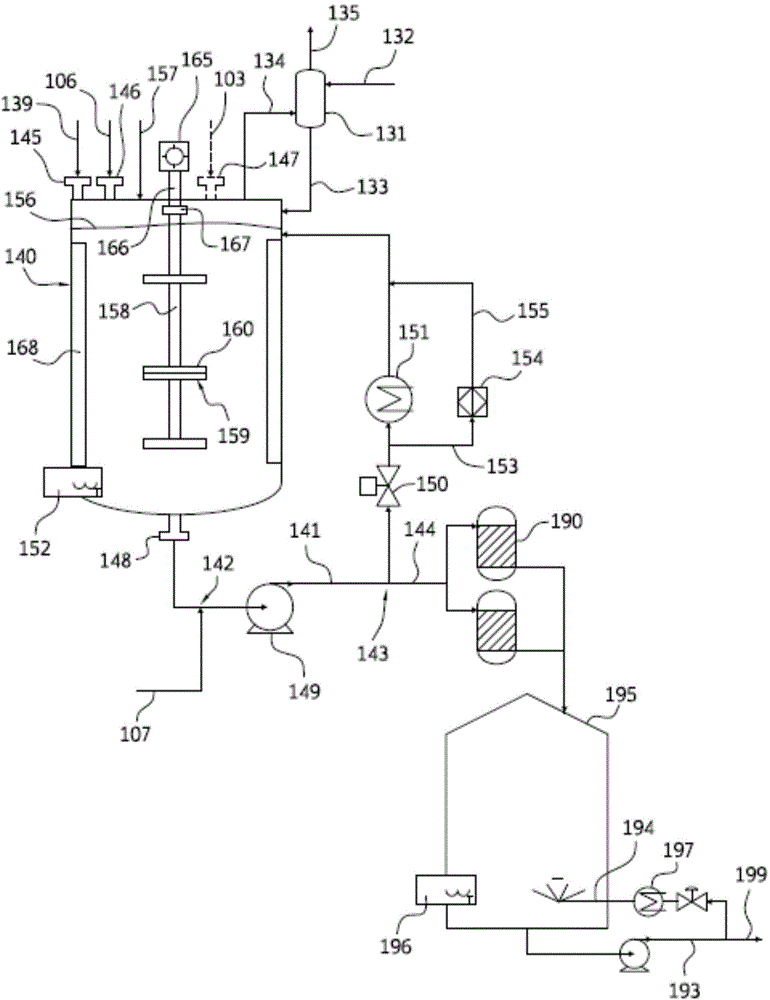

[0144] Modeling for the production of nylon salt solutions according to a continuous process. The nylon salt solution includes water and hexamethylene diamine adipate. The model was set up to achieve a salt concentration of 63% in the nylon salt solution and to achieve a target pH of 7.500. The feed rate of AA was determined based on the desired production of the nylon salt solution. The HMD and water feed rates can be determined based on the desired salt concentration and pH. Adipic acid was moved from the powder discharge system to the loss-in-weight feeder with low variability as described in Example 1.

[0145] The AA powder from the loss-in-weight feeder was directly fed to the continuous stirred tank reactor through a drop trough of nitrogen gas at 20-30 nm 3 / h rate injection to continuously clean the discharge machine and the vapor chute generated in the reactor.

[0146] The DCS set point for the loss-in-weight adipic acid feed rate was determined using a DCS mode...

Embodiment 3

[0161] The nylon salt solution was prepared as in Example 2, except that the on-line pH measurement was carried out under laboratory conditions: at about 25°C, at a concentration of about 9.5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com