Coating solution, modified silicon dioxide film and preparation method thereof

A technology of silicon dioxide film and coating liquid, applied in coating, instrument, optics, etc., can solve the problems of not being generally available, expensive optical film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

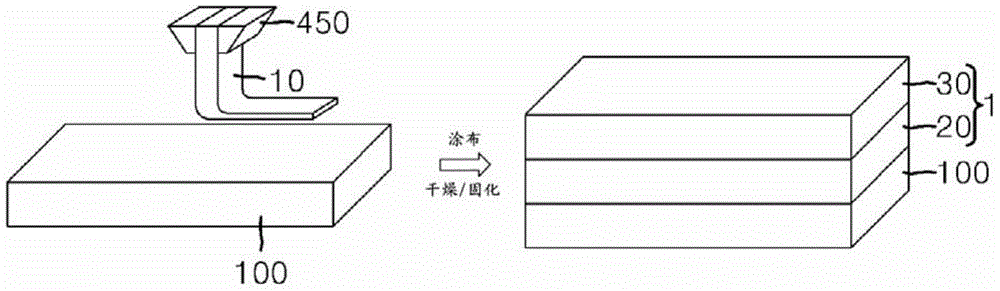

[0097] Next, an embodiment of the present invention will be described. In Example 1, a modified silica film was prepared by the following preparation method.

[0098] As an undiluted solution of polysilazane solution, NAX120-20 (AZ Electronic Materials Co., Ltd.) was prepared. Hereinafter, the undiluted solution is also referred to as "undiluted polysilazane solution". The undiluted polysilazane solution contained 20 wt% polysilazane. In addition, the solvent of the undiluted polysilazane solution was dibutyl ether (surface tension of 22.4) and contained an amine catalyst.

[0099] Next, a predetermined amount of dibutyl ether was added to 9.9 parts by weight of the undiluted polysilazane solution, followed by stirring slowly for 10 minutes, thereby preparing a polysilazane solution. Here, the amount of dibutyl ether added to the undiluted polysilazane solution was determined so that the content of the solid (polysilazane+reactive fluoropolymer) in the coating liquid was 2 ...

Embodiment 2 to 14 and comparative example 1 to 4

[0106] In Examples 2 to 14 and Comparative Examples 1 to 4, in addition to changing the weight ratio of polysilazane to reactive fluoropolymer, the type of reactive fluoropolymer, the type of fluorinated solvent, the The same process as in Example 1 was followed except for the presence and concentration of the reactive fluoropolymer solution. Table 1 shows the amount (parts by weight) of solid, the weight ratio of polysilazane to reactive fluoropolymer, the presence of fluorine-containing solvent and the reactive content according to Examples 1 to 14 and Comparative Examples 1 to 4, respectively. Concentration of Fluoropolymer Solution.

[0107] Table 1

[0108]

[0109] Among reactive fluoropolymers (fluoropolymers), ※1 indicates KY-108 (surface tension of 16.5, Shin-Etsu Chemical Co., Ltd.), and ※2 indicates OPTOOL DSX (surface tension of 15.9, Daikin Industries Co., Ltd. ). Unmarked cases indicate KY-164 (Shin-Etsu Chemical Co., Ltd.).

[0110] In the column of the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com