Additive for fracturing proppant, fracturing proppant and preparation method

A fracturing proppant and additive technology, used in chemical instruments and methods, earthwork drilling, and fluid production, can solve the problems of low cost performance and high production costs, and achieve the advantages of low cost, reduced preparation cost, and reduced firing temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

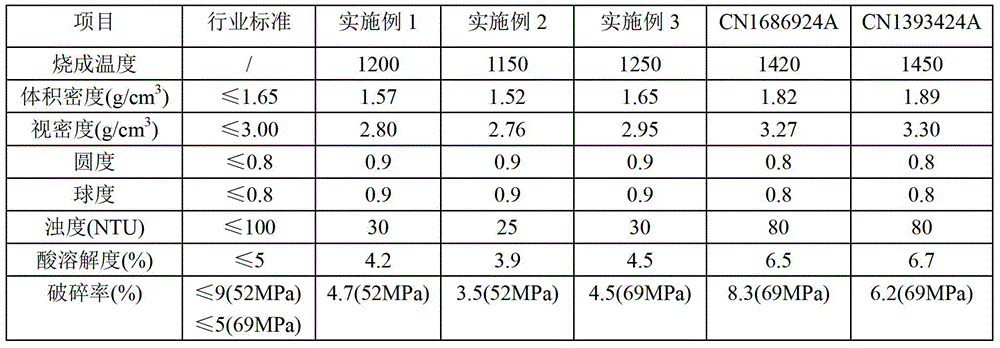

Embodiment 1

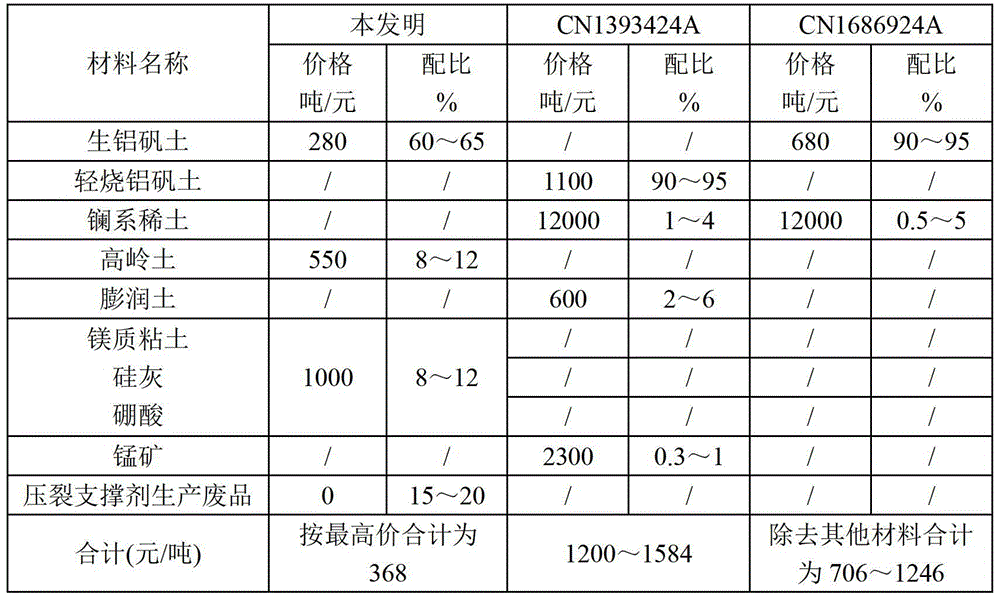

[0029] The additive for fracturing proppant in this embodiment is composed of the following components in weight percent: 16% of industrial boric acid, 68% of magnesia clay, and 16% of silica fume.

[0030] The pressure proppant in this example is composed of the following components in weight percentage: 60% of low-grade bauxite, 12% of calcined kaolin, 20% of fracturing proppant production waste, and 8% of additives for fracturing proppant.

[0031] The preparation of pressure proppant in this embodiment comprises the following steps:

[0032] (1) The low-grade bauxite, fracturing proppant production waste, and calcined kaolin are respectively crushed into 30mm particles by a jaw crusher, and then loaded into the batching bin, and the ratio (weight percentage) is set for each bin. Then put the additive for fracturing proppant into the batching bin and set the ratio, each bin is fed according to the set ratio to the ball mill to be ground into a fine powder with a particle si...

Embodiment 2

[0035] The additive for fracturing proppant in this embodiment is composed of the following components in weight percent: 18% industrial boric acid, 65% magnesia clay, and 17% silica fume.

[0036] The pressure proppant in this example is composed of the following components in weight percentage: 55% of low-grade bauxite, 15% of calcined kaolin, 25% of fracturing proppant production waste, and 5% of additives for fracturing proppant.

[0037] The preparation of pressure proppant in this embodiment comprises the following steps:

[0038] (1) The low-grade bauxite, fracturing proppant production waste, and calcined kaolin are respectively crushed into 30mm particles by a jaw crusher, and then loaded into the batching bin, and the ratio (weight percentage) is set for each bin. Then put the additive for fracturing proppant into the batching bin and set the ratio, each bin is fed according to the set ratio to the ball mill to be ground into a fine powder with a particle size of 400...

Embodiment 3

[0041]The additive for fracturing proppant in this embodiment is composed of the following components in weight percent: 17.5% boric acid, 70% magnesia clay, and 12.5% silica fume.

[0042] The pressure proppant in this example is composed of the following components in weight percentage: 65% of low-grade bauxite, 8% of calcined kaolin, 15% of fracturing proppant production waste, and 15% of additives for fracturing proppant.

[0043] The preparation of pressure proppant in this embodiment comprises the following steps:

[0044] (1) The low-grade bauxite, fracturing proppant production waste, and calcined kaolin are respectively crushed into 30mm particles by a jaw crusher, and then loaded into the batching bin, and the ratio (weight percentage) is set for each bin. Then put the additive for fracturing proppant into the batching bin and set the ratio, each bin is fed according to the set ratio to the ball mill to be ground into a fine powder with a particle size of 400 mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com