Improved structure of coppered wire hang stripping recovery groove

A technology of improved structure and recovery tank, which is applied in the direction of electrolysis components, cells, electrolysis process, etc., can solve the problems of polluting the working environment and the health of operators, increasing the cost of waste gas recovery and waste gas treatment, and consuming nitric acid solution, so as to improve the efficiency of electrolysis Efficiency, accelerated permeability, and efficient recovery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

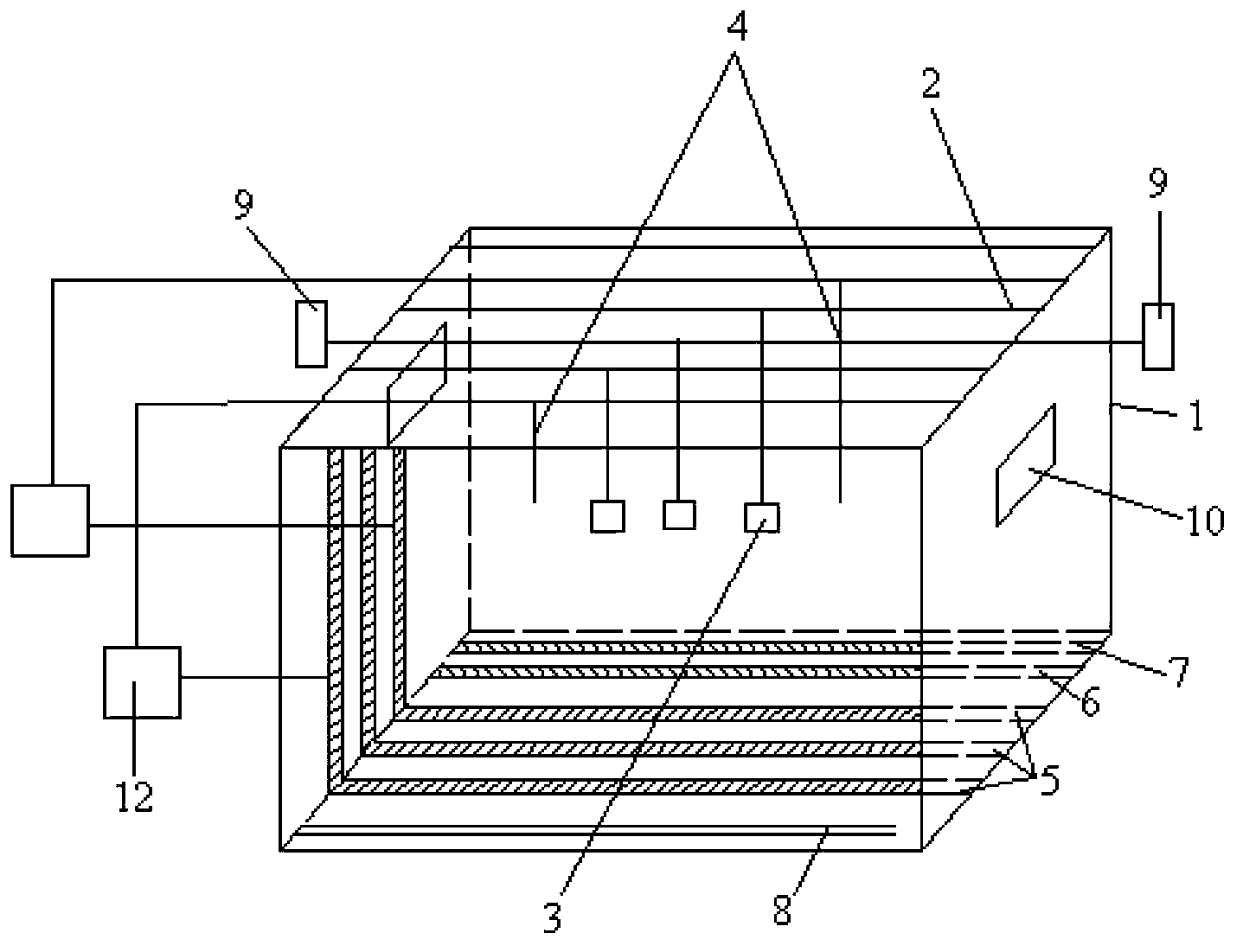

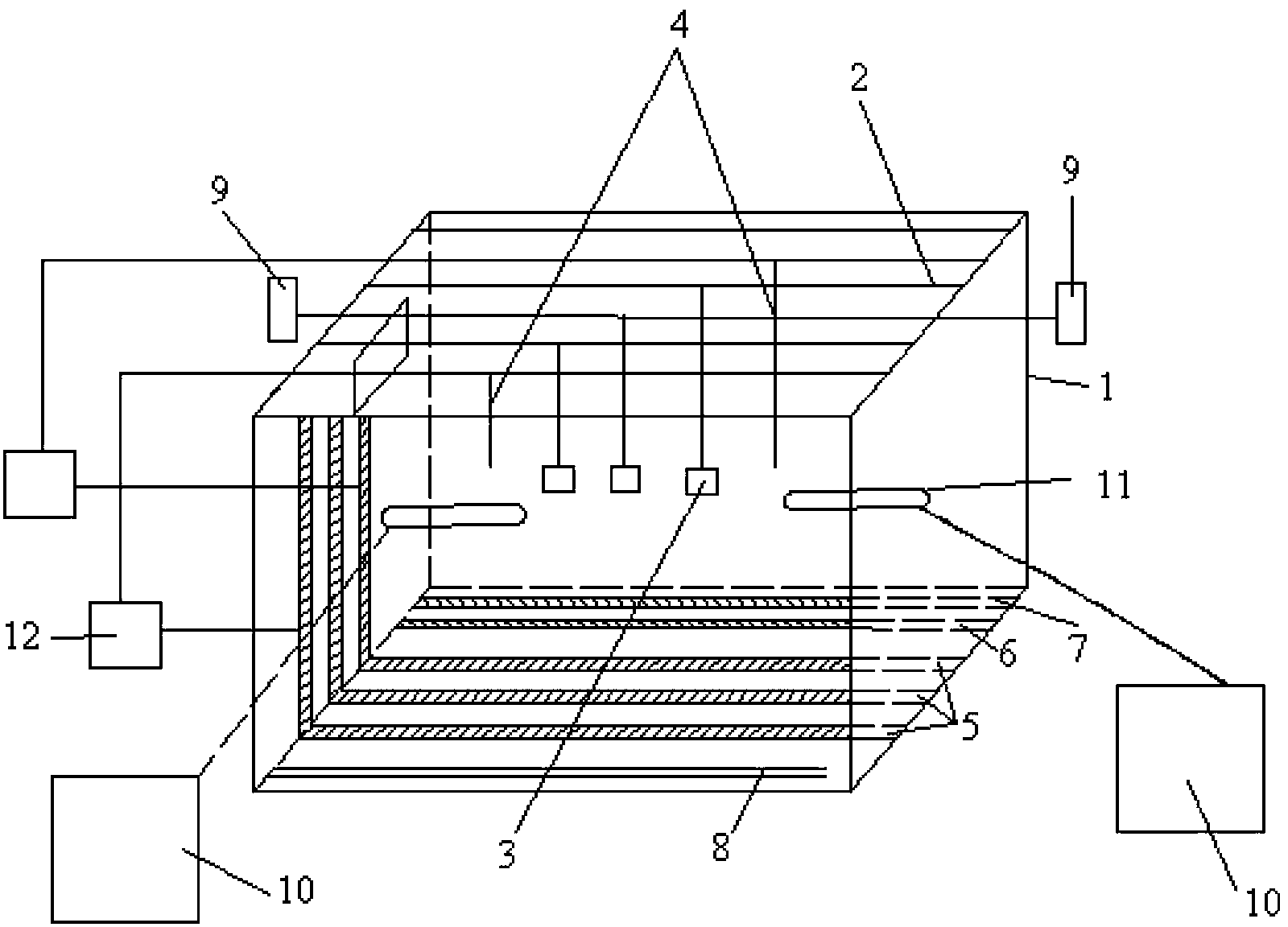

[0023] An embodiment of the improved structure of the copper-plated wire stripping and hanging recovery tank of the present invention will be described in detail below with reference to the accompanying drawings.

[0024] The improved structure of a copper-plated wire stripping and hanging recovery tank of the present invention includes an electrolytic tank 1 equipped with an electrolytic solution, several flying targets 2 and several copper plates 5, and the corresponding two side vertical sides of the electrolytic tank are There are several fixed bases arranged at intervals symmetrically on the top, each flying target is positioned and erected between the two symmetrical fixed bases, and the plurality of flying targets are electrically connected to the positive pole of the power supply The flying target is provided with a copper-plated hanger 3, and the plurality of copper plates are all electrically connected to the negative pole of the power supply and positioned on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com