Electric cylinder with buffer

A technology of electric cylinders and buffers, which is applied in the direction of electric components, shock absorbers, shock absorbers, etc., to achieve the effects of easy installation and use, reduction of transmission errors, and reduction of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described below based on the illustrated embodiments.

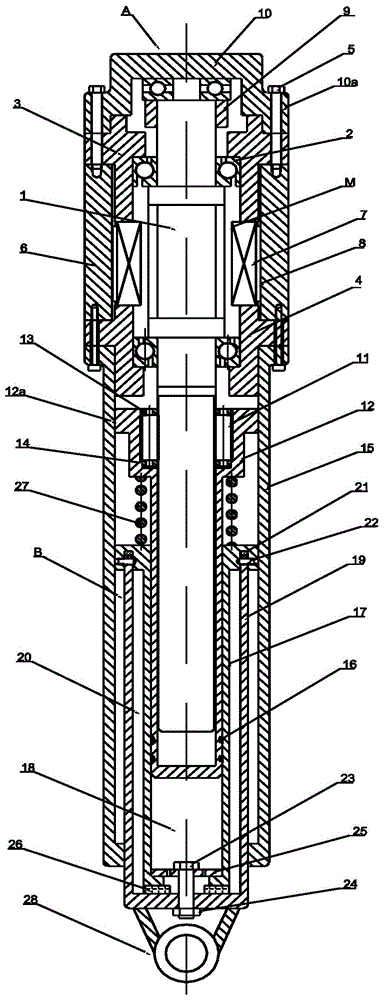

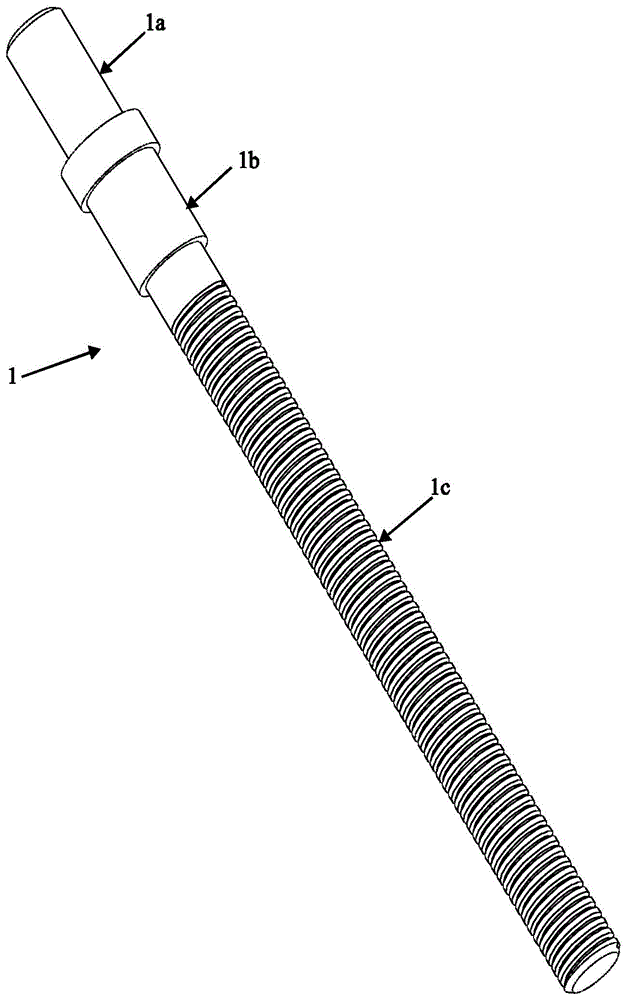

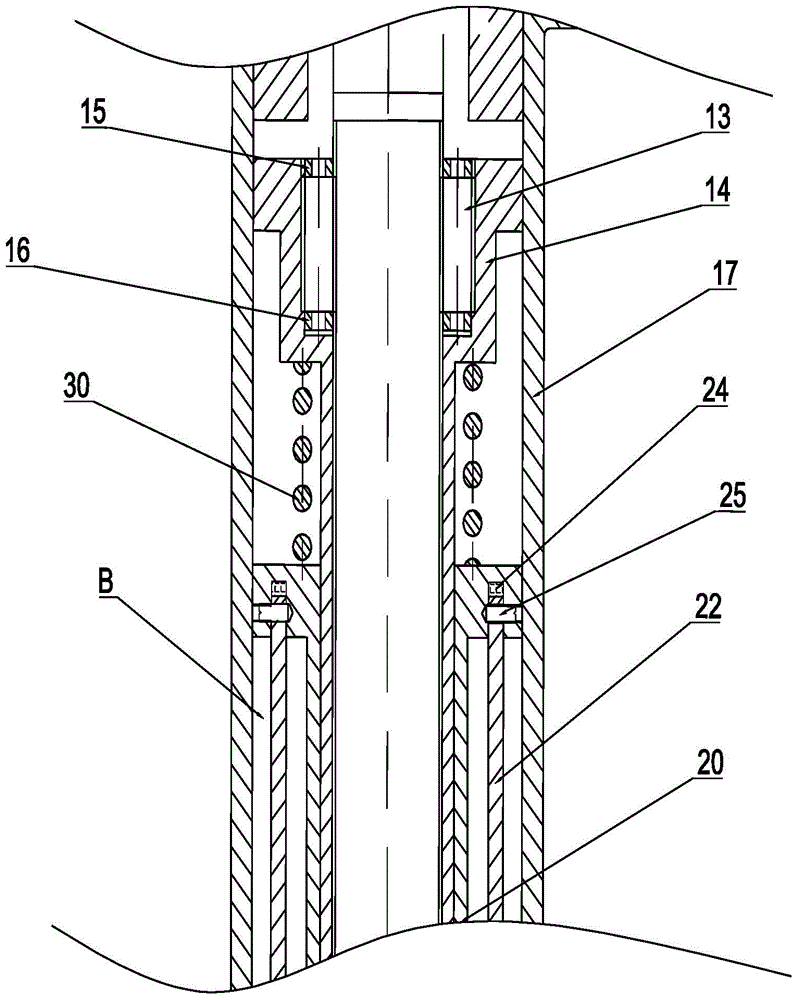

[0040] See figure 1 — image 3 , the present invention has an electric cylinder with a buffer, which is composed of a screw 1, a motor rotor 1b, an angular contact ball bearing 2, an annular thrust pad 13, an annular thrust pad 24, a long bolt 5, and an electric cylinder cylinder 6, motor stator 7, spline 8, encoder 9, end cover 10, threaded roller 11, nut cylinder 12, retaining ring 13, 14, electric cylinder cylinder 15, piston ring 16, buffer inner cylinder 17, Buffer outer cylinder 19, sealing washer 21, retaining ring 25, ring spacer 26, rigid spring 27, bracket 28 and connector stud 22, bolt 23, nut 24 are composed, and the position connection relationship between them is:

[0041] Such as figure 1 The electric cylinder A shown has: a drive motor M, a lead screw 1 integrated with the motor stator, and a nut barrel 12 as a buffer B for the piston rod. Angular contact ball beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com