Ionomer-poly(vinylalcohol) blends and coatings

A vinyl alcohol, ionomer technology, applied in coating, chemical recycling and other directions, can solve the problem of complex ionomer dispersion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

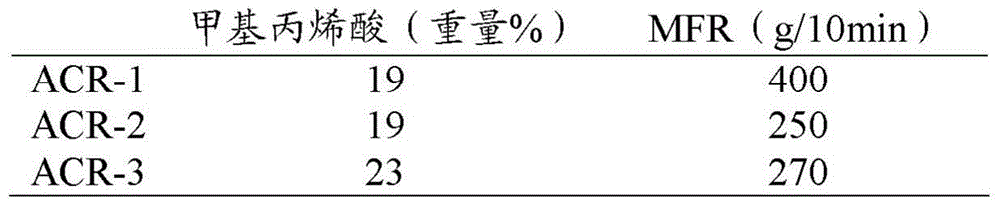

[0188] Table 1 summarizes the ethylene-methacrylic acid dimers used to prepare the ionomers in Table 2 having the indicated weight % of methacrylic acid interpolymerized units based on the total acid copolymer. Ionomers were prepared from acid copolymers using standard conditions. Melt flow rate (MFR) was determined according to ASTM D1238 at 190°C using a 2160 g load; a similar test is ISO1133.

[0189] Table 1

[0190]

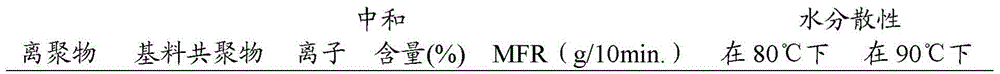

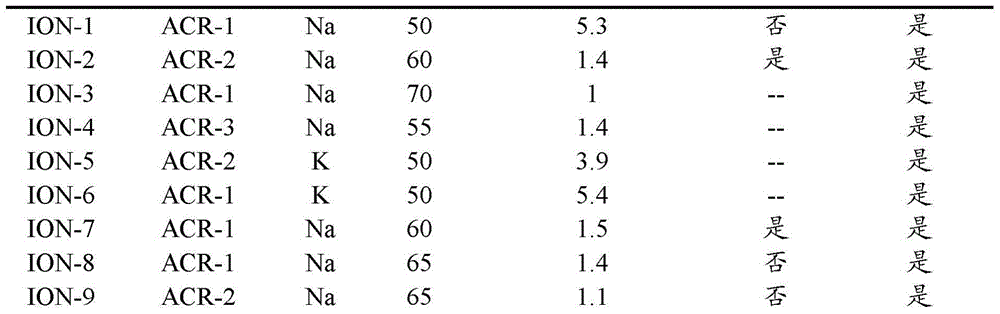

[0191] ionomer

[0192] Table 2 summarizes the ionomers derived from ethylene methacrylic acid dimer, showing the percentage of carboxylic acid groups neutralized with sodium hydroxide to form the sodium salt or with potassium carbonate to form the potassium salt. Water dispersibility was determined according to the following method, which shows the addition of unneutralized acid copolymer or ionomer to hot water. The process yields a mixture of water and a 10% solids loading by weight (weighed before adding to the water). Add 500 mL of distilled ...

example 1-24 and comparative example C1-C7

[0213] The examples summarized in Tables 6 and 7 demonstrate coated paperboard with aqueous dispersions. Aqueous ionomer-PVOH dispersions were formulated according to the general procedure above. The substrate is 0.22 inch thick, nominally 77 lb basis weight, paperboard coated with clay on one side for printing, available under the trade name Bleached Boards were obtained commercially from Rock Tenn Converting Company (Demopolis AL). An 8 inch x 11 inch substrate sample was coated on the side opposite the clay coating by weighing the sample and then attaching it to a flat piece of plywood with a spring clip. Approximately 80 mL of the ionomer-PVOH dispersion prepared above was applied to the clamped end, and the dispersion was spread and smoothed in one stroke with a 0.0036 inch wire wound Meyer rod to cover the remainder of the paper sample. Excess dispersion is removed during the diffusion operation. Due to the difficulty of drying to constant weight, the dry coating we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com