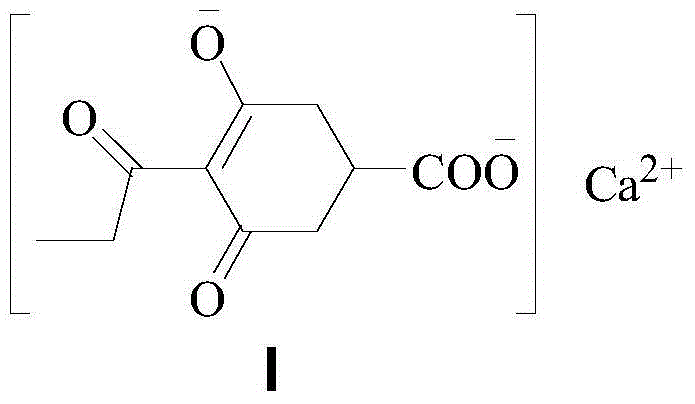

Method for preparing calcium3-oxido-5-oxo-4-propionyl cyclohex-3-enecarboxylate

A technology of propionyl cyclohexane carboxylate calcium and propionyl cyclohexane carboxylate ethyl ester, applied in the field of preparation of 3,5-dioxo-4-propionyl cyclohexane carboxylate calcium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

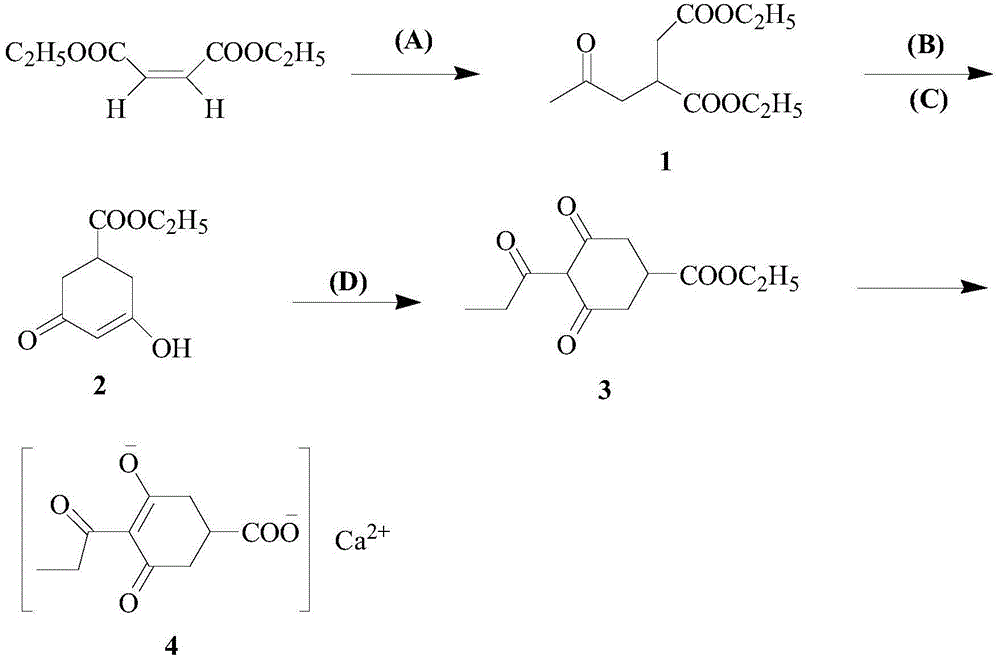

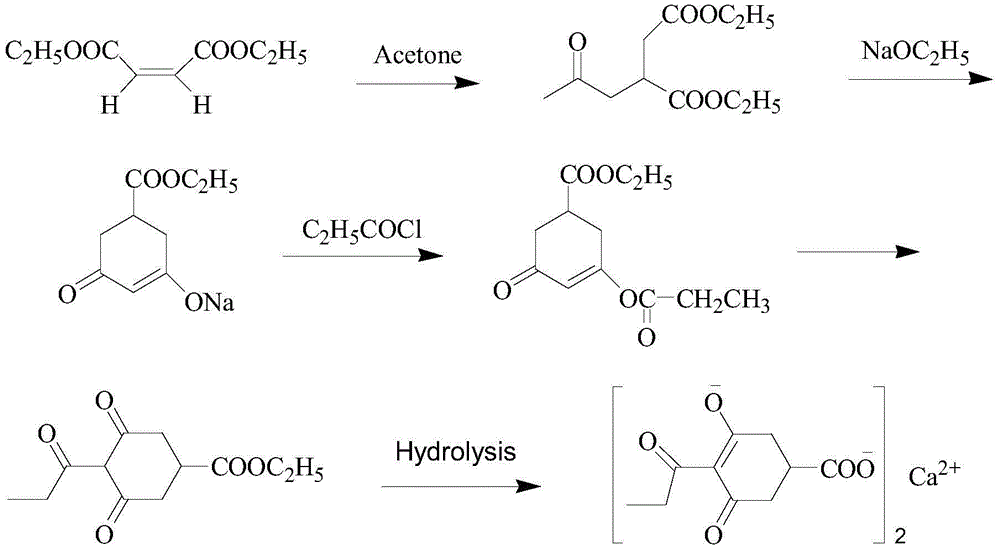

Method used

Image

Examples

Embodiment 1

[0030] Diethyl maleate (500.00 g, 2.91 mol), acetone (253.00 g, 4.37 mol) and diethylamine (21.24 g, 0.291 mol) were placed in a 2 L autoclave and reacted at 150 °C for 24 h, recycle the acetone solvent to obtain the product 1 : Diethyl acetonyl succinate. Transfer diethyl acetonyl succinate to a three-necked round-bottomed flask and add ethanol (520 mL), add sodium ethoxide ethanol solution (1 mol / L, 2.49 mol) dropwise under mechanical stirring and control the reaction temperature After the dropwise addition is completed, continue to stir at 5 °C for 2 h, then rise to room temperature and stir for 12 h; after the solution is cooled below 5 °C, add a certain amount of glacial acetic acid to neutralize the reaction solution, and recover ethanol under reduced pressure , to get the product 2 : Ethyl 3,5-dioxocyclohexanecarboxylate. Add 1,2-dichloroethane (5 L) to a reaction vessel containing ethyl 3,5-dioxocyclohexanecarboxylate, and add propionyl chloride (204.29 g, 2.17 mol)...

Embodiment 2

[0032] Diethyl maleate (500.00 g, 2.91 mol), acetone (253.00 g, 4.37 mol) and diethylamine (21.24 g, 0.291 mol) were placed in a 2 L autoclave and reacted at 150 °C for 28 h, recycle the acetone solvent to obtain the product 1 : Diethyl acetonyl succinate. Transfer diethyl acetonyl succinate to a three-necked round-bottomed flask and add ethanol (520 mL), add sodium ethoxide ethanol solution (1 mol / L, 2.49 mol) dropwise under mechanical stirring and control the reaction temperature After the dropwise addition is completed, continue to stir at 5 °C for 2 h, then rise to room temperature and stir for 12 h; after the solution is cooled below 5 °C, add a certain amount of glacial acetic acid to neutralize the reaction solution, and recover ethanol under reduced pressure , to get the product 2 : Ethyl 3,5-dioxocyclohexanecarboxylate. Add 1,2-dichloroethane (5 L) into a reaction vessel containing ethyl 3,5-dioxocyclohexanecarboxylate, and add propionyl chloride (204.29 g, 2.17 mo...

Embodiment 3

[0034]Diethyl maleate (500.00 g, 2.91 mol), acetone (253.00 g, 4.37 mol) and diethylamine (21.24 g, 0.291 mol) were placed in a 2 L autoclave and reacted at 150 °C for 32 h, recycle the acetone solvent to obtain the product 1 : Diethyl acetonyl succinate. Transfer diethyl acetonyl succinate to a three-necked round-bottomed flask and add ethanol (520 mL), add sodium ethoxide ethanol solution (1 mol / L, 2.49 mol) dropwise under mechanical stirring and control the reaction temperature After the dropwise addition is completed, continue to stir at 5 °C for 2 h, then rise to room temperature and stir for 12 h; after the solution is cooled below 5 °C, add a certain amount of glacial acetic acid to neutralize the reaction solution, and recover ethanol under reduced pressure , to get the product 2 : Ethyl 3,5-dioxocyclohexanecarboxylate. Add 1,2-dichloroethane (5 L) to a reaction vessel containing ethyl 3,5-dioxocyclohexanecarboxylate, and add propionyl chloride (204.29 g, 2.17 mol) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com