Method for forming a complete anti-seepage curtain in two mediums of rock and soil

A technology of anti-seepage curtain and medium, which is applied in the direction of construction, sheet pile wall, foundation structure engineering, etc. It can solve the problems of low consolidation strength, use, and construction technology of anti-seepage curtain that cannot be used in rock mass, and achieve the applicable stratum Wide, Regular Aperture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further describe the present invention, the method for forming a complete anti-seepage curtain in two media of rock and soil of the present invention will be further described in detail below with reference to the accompanying drawings and examples.

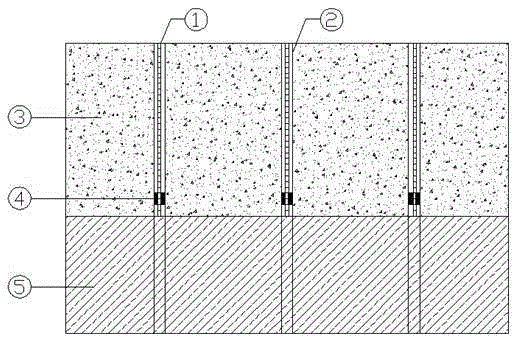

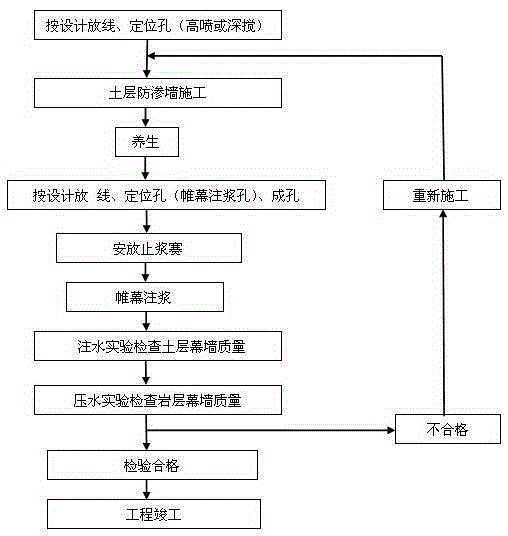

[0029] Depend on figure 1 The typical cross-sectional view of the complete vertical anti-seepage curtain wall constructed by the method of the present invention is shown in combination with figure 2 It can be seen that the method of the present invention to form a complete anti-seepage curtain in two media of rock and soil adopts the following process steps:

[0030] 1) In the upper soil layer, according to the design requirements, lay out lines, fixed-height spray piles or deep stirring pile holes in the area where vertical anti-seepage curtain walls are required.

[0031] 2) According to the design and in accordance with the corresponding specifications, the construction of high-spray piles or deep-stirred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com