Soil-squeezing hole-forming and pile-forming method for threaded pile

A threaded pile and hole-forming technology, which is applied in the direction of drilling equipment and methods, earth drilling, and sheet pile walls, can solve the problems of reduced shear resistance of the soil around the pile and large fluctuations in the bearing capacity of the threaded pile, and achieve high bearing capacity. , fully squeezed soil, and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Example Threaded piles squeezed soil to form holes and pile-forming methods

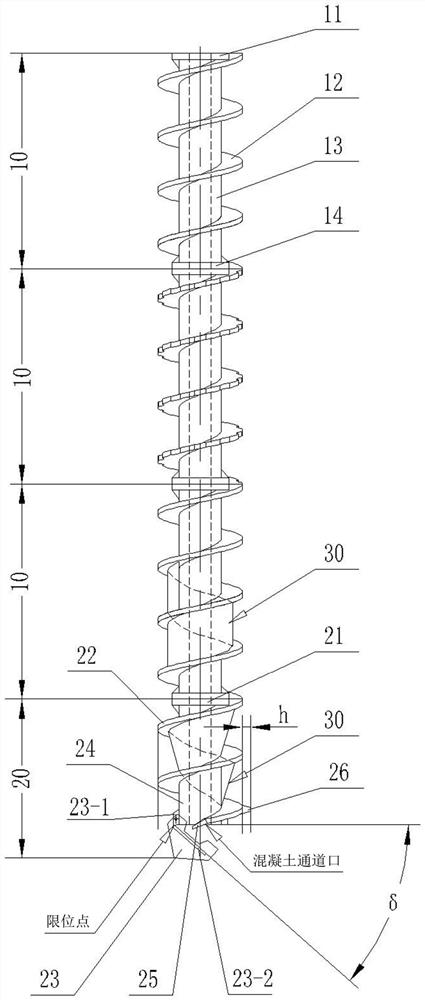

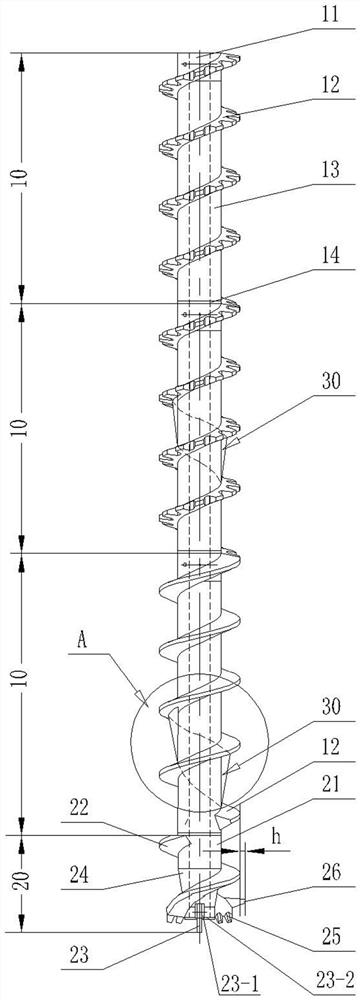

[0032] like Figure 1-Figure 4 As shown, a soil extruding drilling tool with a screw extruding soil body comprises a drill pipe (10) and a drill bit (20).

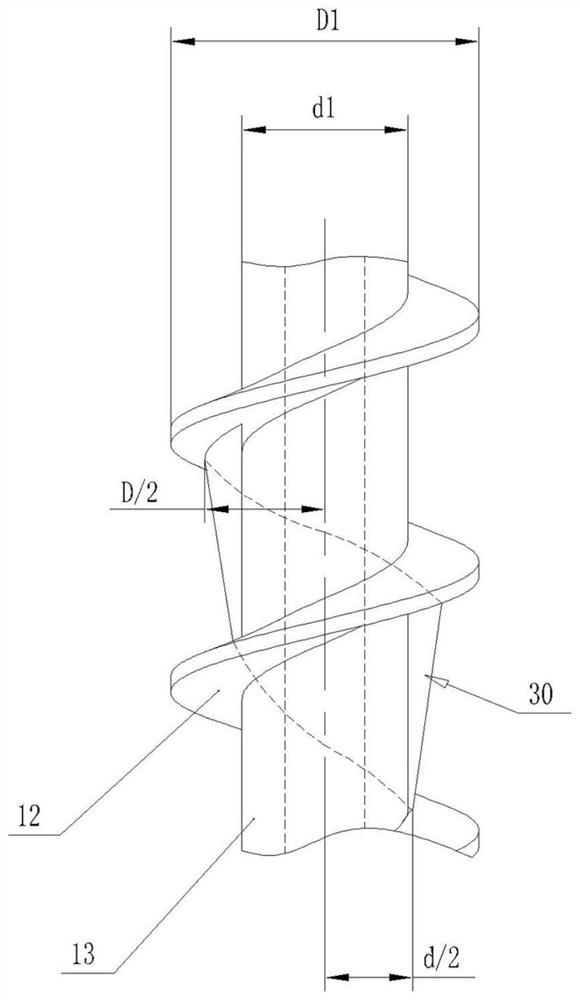

[0033] The drill pipe (10) can be connected in series with one or more sections. The drill pipe (10) includes a joint I (11), a helical blade I (12), a core pipe I (13) and a joint II (14). The joint I (11) and the joint II (14) are respectively coaxially fixed on both ends of the core pipe I (13) and integrated with the core pipe I (13). The helical blade I (12) is helically wound on the outer surfaces of the joint I (11), the core pipe I (13) and the joint II (14). The inner cavity of the drill pipe (10) is a channel for the concrete to pass through. The joint I (11) and the joint II (14) can be hexagonal (or octagonal) joints with internal and external inlay matching, and can also be a combination of flange positioning and matching. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com