Well drilling pressurizing speed-up device

A speed booster and supercharger technology, which is applied to drilling equipment, liquid/gas jet drilling, and driving devices for drilling in boreholes. It can solve the problems of increasing processing difficulty, reducing reliability, and poor safety. Good speed effect, slow solution speed, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

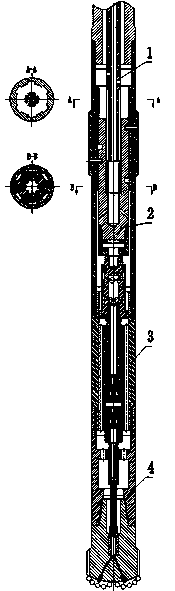

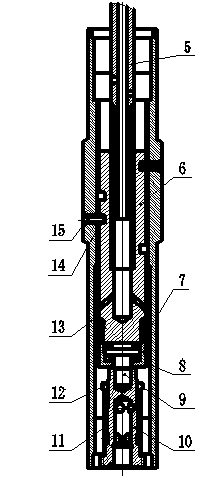

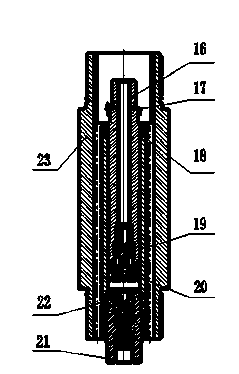

[0016] The structure and implementation of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0017] First, connect the power mechanism, reversing and filtering mechanism, booster system and booster bit system through threads to form the entire drilling booster (see figure 1 ). The outer surface of the rotating mandrel (6) is processed with double helical grooves, one end of the pin shaft (15) slides relatively in the helical groove, and the other end is fixedly installed on the cylinder (13); the screw motor output shaft (5) and the rotating core The shafts are matched by splines, and the rotation of the motor drives the rotating mandrel to rotate together. Since the pin shaft is fixed, the rotating mandrel processed with spiral grooves must also move up and down while rotating; the rotating mandrel and the filter cylinder (10) pass the thrust The bearing (8) and the connecting bolt (9) are connected, and the filter cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com