Anti-toppling type glass steel tube connecting piece

A kind of glass steel pipe and connector technology, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, pipe element, etc., can solve the problem of unstable support of the connector, avoid tipping, strengthen anti-slip force, and anti-impact force. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

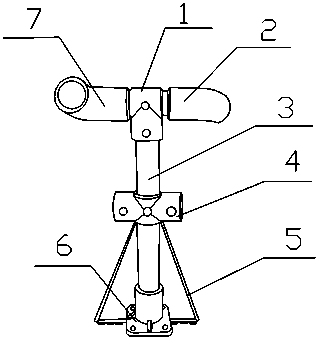

[0017] Such as figure 1 As shown, the present invention includes a first connector 1, a first right-angle elbow 2, a support rod 3, a second connector 4, a tripod 5, a base 6 and a second right-angle elbow 7, and the first connector The two ends of 1 are respectively connected to the first right-angle elbow 2 and the second right-angle elbow 7 by bolts, and the bottom of the first joint 1 is also connected to the support rod 3 by bolts; the bottom of the support rod 3 is connected to the base 6. The middle part of the rod 3 is also sleeved with the second connector 4 ; the top of the tripod 5 is connected to the bottom of the second connector 4 , and the bottom of the tripod 5 is close to the bottom of the base 6 .

[0018] When in use, it is only necessary to connect the glass steel pipes to the corresponding first right-angle elbow and the second right-angle elbow. The first right-angle elbow and the second right-angle elbow are used to connect two glass steel pipes togethe...

Embodiment 2

[0020] In this embodiment, on the basis of Embodiment 1, the preferred specific structure is as follows: the bottom of the triangular support frame 5 is further provided with reinforcing ribs. The setting of reinforcing ribs increases the friction force at the bottom, further enhances its anti-slip force, and avoids dumping.

Embodiment 3

[0022] The preferred specific structure of this embodiment is as follows on the basis of the above-mentioned embodiments: the openings of the first right-angle elbow 2 and the second right-angle elbow 7 are both facing outward.

[0023] The bottom of the base 6 is provided with a groove, and the bottom edge of the tripod 5 is engaged in the groove. Increase the stability of the triangular support frame to prevent it from slipping and affect the supporting effect of the triangular support frame on the support rod.

[0024] Uniform reinforcing ribs are arranged on the bottom of the base 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com