Device and method for detecting internal initial stress of steel structure components based on ultrasonic method

A technology of initial stress and ultrasonic method, which is applied to measuring devices, using sound waves/ultrasonic waves/infrasonic waves to analyze solids, measure forces, etc., can solve problems such as single, undetectable stress, and inability to measure the initial stress of steel structural members, etc., to achieve installation Convenience, low cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

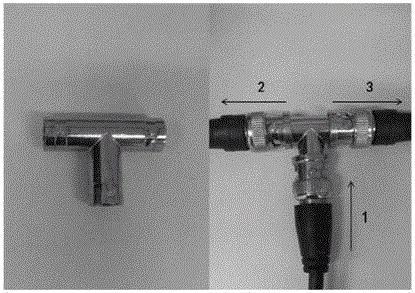

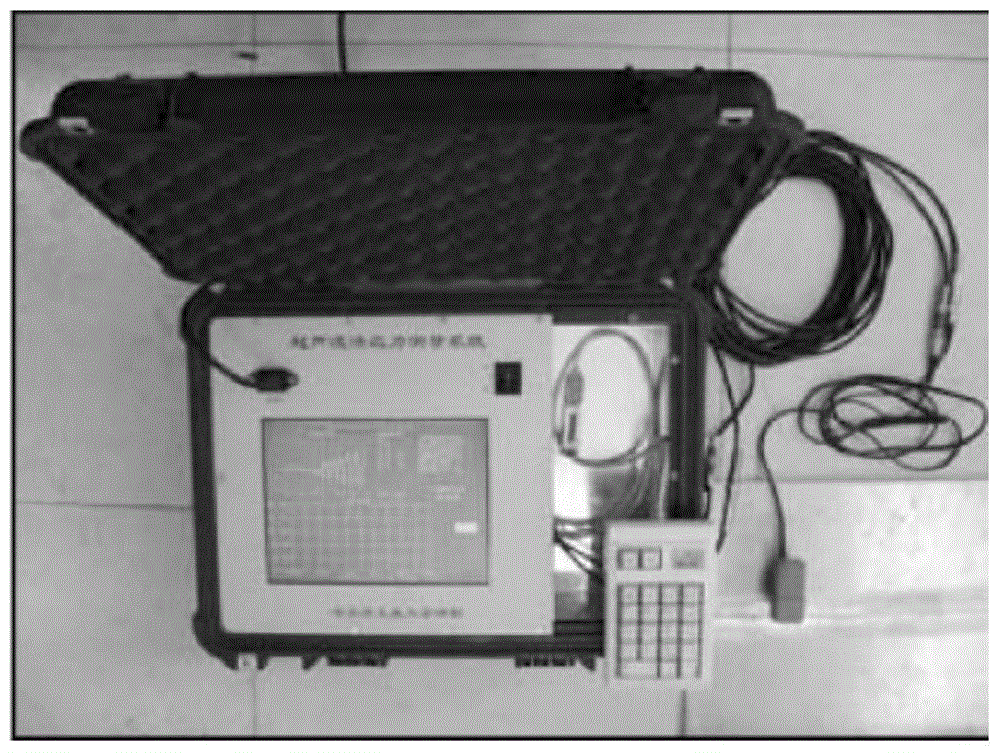

[0069] Embodiment 1 The present invention is based on ultrasonic non-destructive testing of internal initial stress device composition testing method of steel structural members and explanation of related principles

[0070] The principle of the non-destructive testing method for the internal initial stress of steel structural members based on the ultrasonic method is as follows.

[0071] In the elastic range, the relationship between the stress and strain inside the material is generally considered to be a linear relationship, which is the familiar Hooke's law. As measurement techniques developed, it was discovered that elastic "constants" such as Young's modulus were not fixed but varied slightly according to the magnitude of the strain. Experiments have shown that when the atoms inside the material are compressed by compressive stress, the elastic modulus becomes larger, and when the atoms are pulled apart by tensile stress, the elastic modulus becomes smaller. These situat...

Embodiment 2

[0117] Embodiment 2 The present invention is based on the ultrasonic method for non-destructive detection of the internal initial stress device of the steel structural member for the test of the internal initial stress of the steel plate

[0118] In order to verify the accuracy of the method of the present invention for detecting the internal stress of the steel structural member, the following test and comparative test for detecting the internal initial stress of the steel structural member were done.

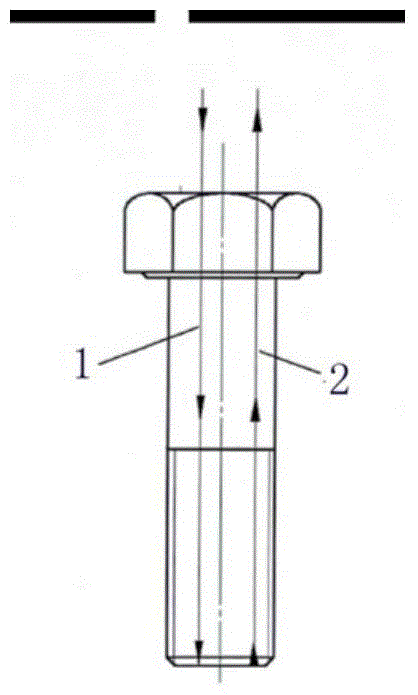

[0119] Select the type of steel structural member as a representative and relatively simple steel structural member—steel plate. The size of the steel plate is 600mm long, 40mm wide, and 8mm thick. The physical schematic diagram of the steel plate is as follows Figure 23 shown. In this test, the center frequency of the ultrasonic transmitting probe and receiving probe is selected as 5 MHz, that is, the axial stress value at a depth of 1.5 mm from the surface of the component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com