Transformer secondary winding zero current detection circuit for led drive power supply

A technology of zero current detection and secondary winding, applied in the direction of measuring current/voltage, measuring electrical variables, instruments, etc., can solve the problem of poor output constant current effect of LED drive power supply, change of load adjustment rate and linear adjustment rate of LED drive power supply Poor and other problems, to achieve a good output constant current effect, reduce the effect of delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

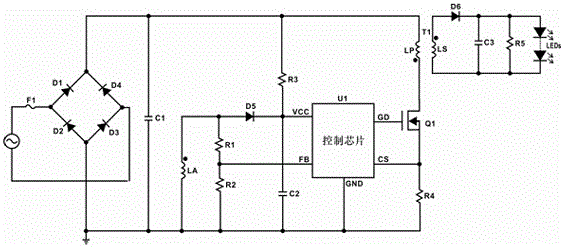

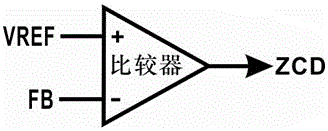

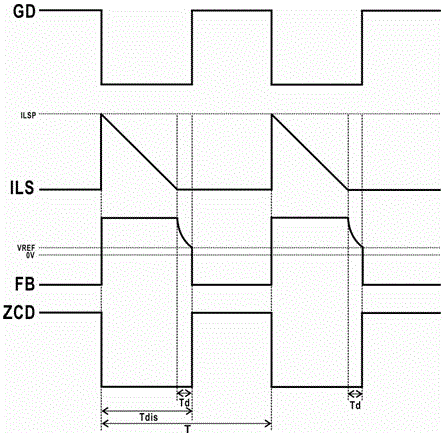

[0023] The invention solves the problem of excessive delay between the zero-crossing moment of the secondary winding current and the zero-current detection signal in the traditional transformer secondary winding zero-current detection technology, and provides a transformer secondary winding zero-current detection which solves the problem circuit. The zero-current detection signal is triggered by detecting the falling edge of the voltage across the secondary winding of the transformer, which greatly reduces the delay between the zero-crossing moment of the secondary winding current and the zero-current detection signal ZCD, effectively solving the traditional In the detection technology, the delay between the secondary winding current zero-crossing moment and the zero-current detection signal is too large, so that the zero-current detection signal ZCD can accurately reflect the information of the transformer secondary winding current zero-crossing moment.

[0024] Such as ima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com