Grippers, twisting heads and twisting devices

A twisting and gripping technology, used in textiles and papermaking, electrical components, cable/conductor manufacturing, etc., can solve the problems of high cost, high weight, unadjustable wire end holding force, and achieve the effect of compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

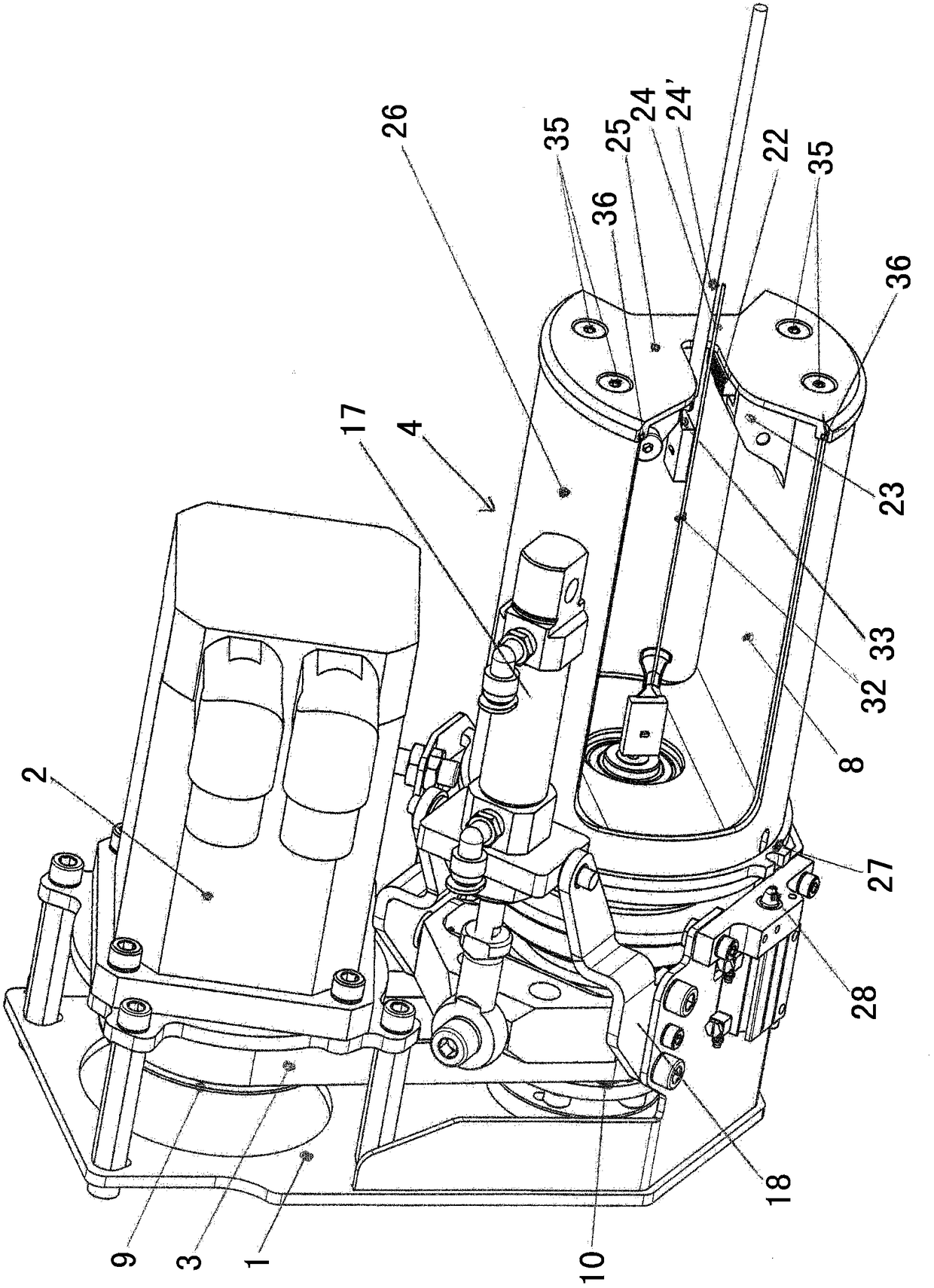

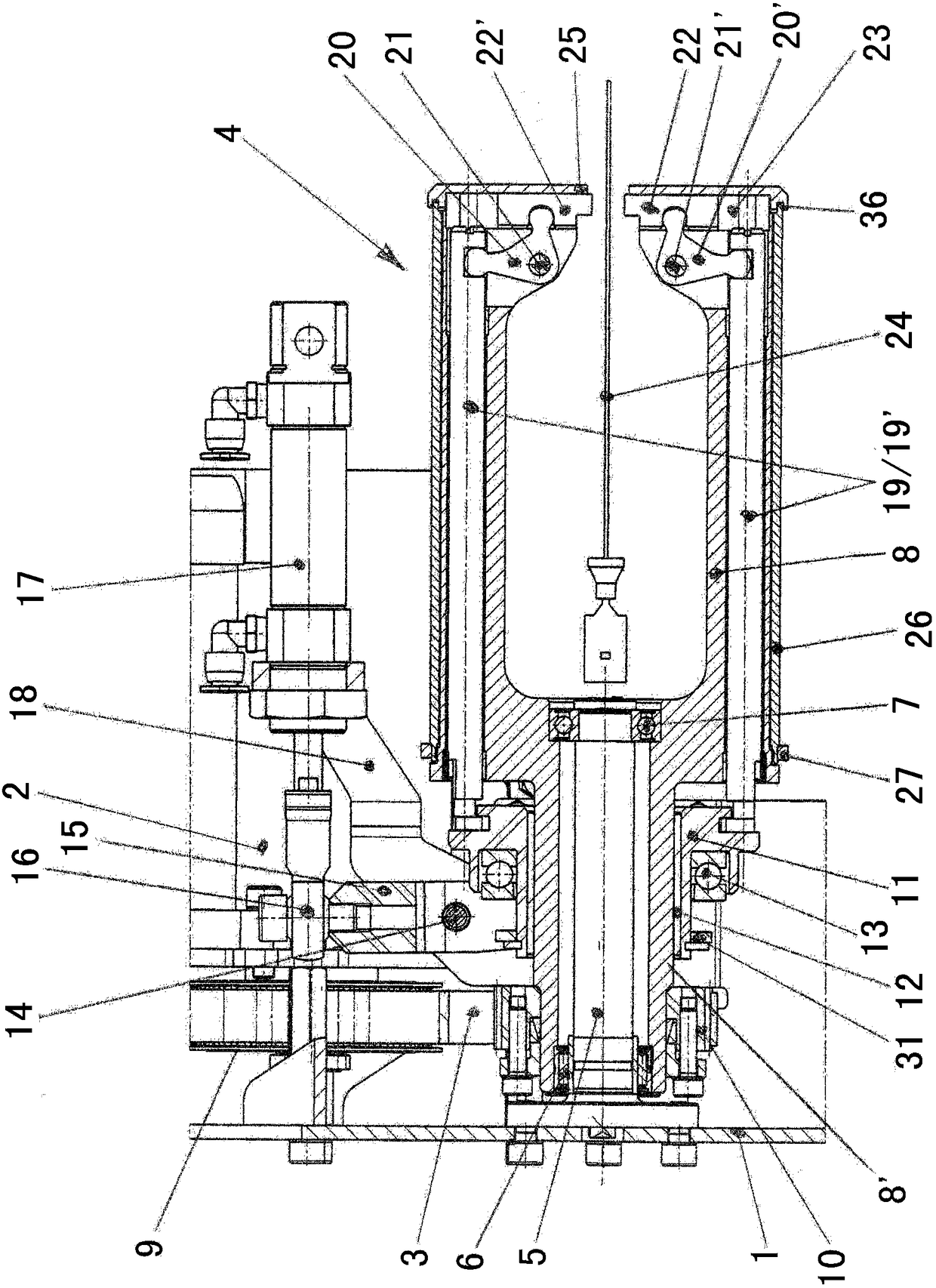

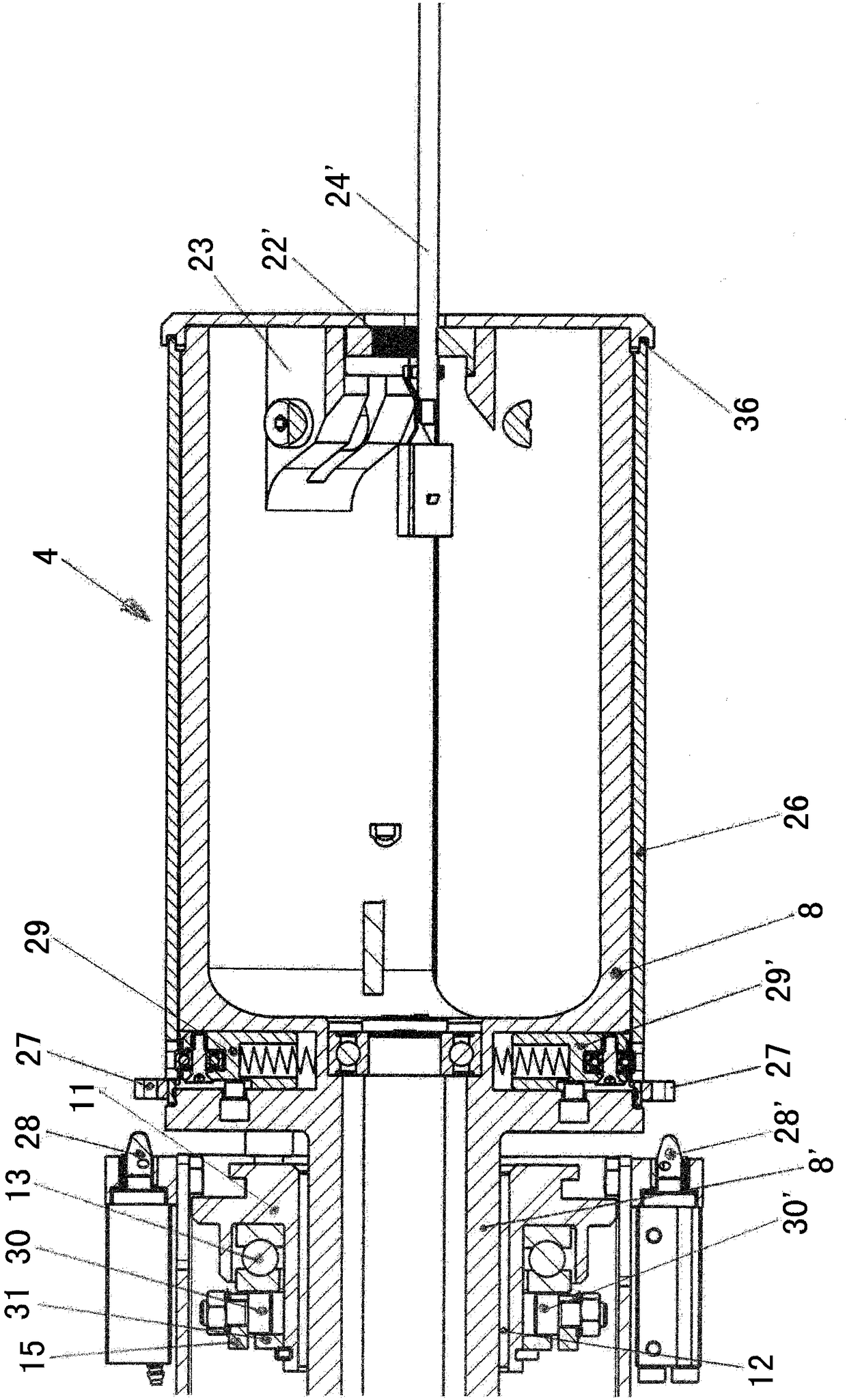

[0034] exist Figure 1 to Figure 4 In the illustrated embodiment shown, the twisting device according to the invention consists of a base 1 on which at least one drive motor 2, preferably a servo drive, for the twisting head 4 is mounted. The drive motor 2 drives the twisting head 4 via, for example, a drive belt 3 (preferably a toothed belt), the twisting head has an actual gripper comprising a plurality of structural components (see in particular for this figure 2 ). Within the scope of the invention, other drives or other transmission elements can also be arranged between the drive motor 2 and the twisting head 4 . Alternatively, a second twisting head can additionally be provided and preferably operated by the same drive motor 2 .

[0035] The first toothed disc 9 fixed on the motor shaft (not shown) of the drive motor 2 transmits the rotational movement via the second toothed disc 10 via the drive toothed belt 3 to the rotatably supported and preferably positioned para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com